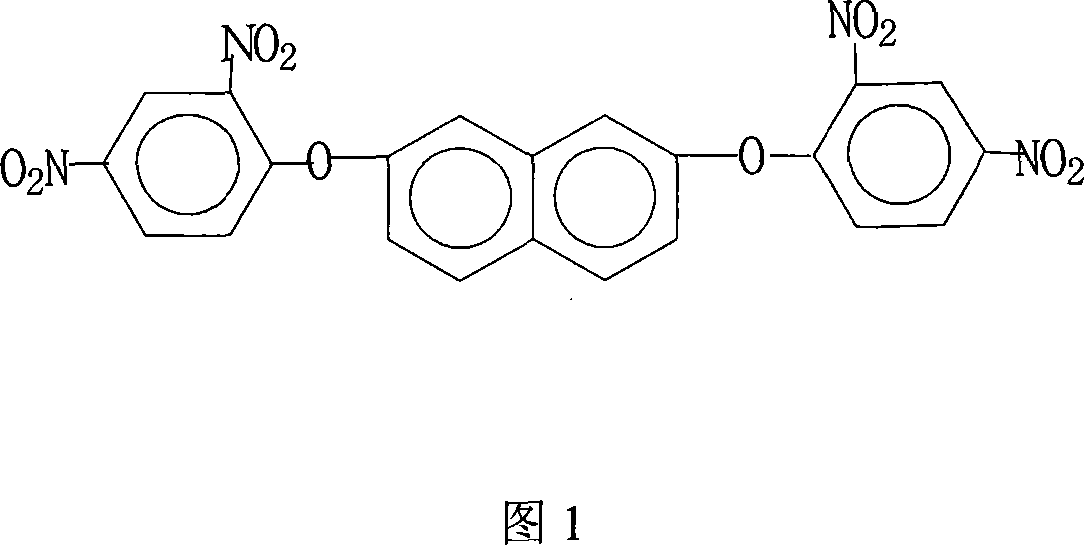

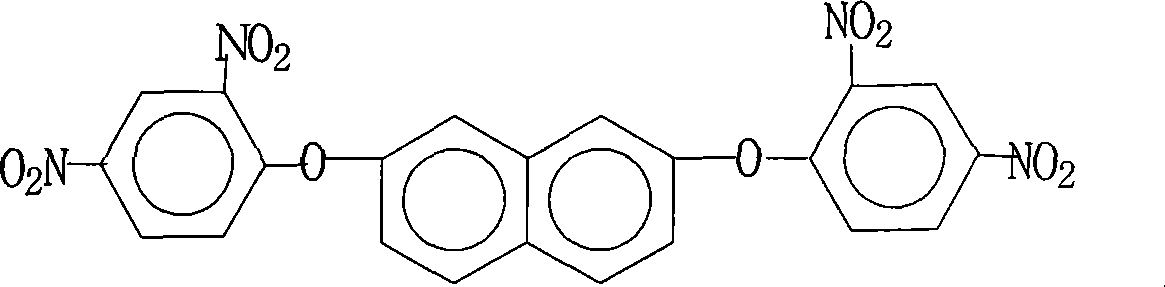

Method for preparing 2,7-di(2,4-dinitrophenoxy) naphthalene

A technology of dinitrophenoxy and dinitro, which is applied in 2 fields to achieve the effects of high product yield and purity, fewer types of use, and convenient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

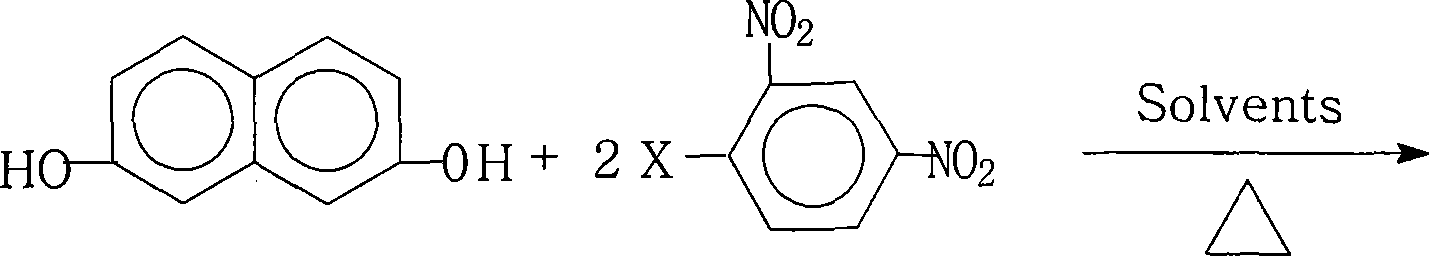

Method used

Image

Examples

Embodiment 1

[0028] 16.0 grams (0.10 moles) of 2,7-naphthalenediol, 44.6 grams (0.22 moles) of 2,4-dinitrochlorobenzene, 110.4 grams (0.80 moles) of potassium carbonate, 700 milliliters of N,N-dimethyl Formamide and 180 milliliters of toluene were put into a reaction kettle, stirred, heated to reflux and separated from water for 18 hours, concentrated the reaction liquid, recovered the solvent for recycling, cooled the reactant system, added water, precipitated a solid product, washed, and dried to obtain 46.7 The 2,7-two (2,4-dinitrophenoxy) naphthalene crystal product of gram, purity is 99.6%, obtain 2,7-bis (2,4-dinitrophenoxy) naphthalene according to actual amount and theoretical amount (49.2 grams), the calculated yield of 2,7-bis(2,4-dinitrophenoxy)naphthalene is 95.1%.

Embodiment 2

[0030] 16.0 grams (0.10 moles) of 2,7-naphthalenediol, 54.4 grams (0.22 moles) of 2,4-dinitrobromobenzene, 55.2 grams (0.40 moles) of potassium carbonate, 150 milliliters of N,N-dimethyl Acetamide and 15 milliliters of xylene were put into a reaction kettle, stirred, heated to reflux and separated from water for 6 hours, concentrated the reaction liquid, recovered the solvent for recycling, cooled the reactant system, added water, precipitated a solid product, washed, dried, and obtained 30.1 grams of 2,7-bis(2,4-dinitrophenoxy)naphthalene crystal product, the purity is 99.2%, according to the actual obtained 2,7-bis(2,4-dinitrophenoxy)naphthalene amount and theoretical amount (49.2 grams), the calculated yield of 2,7-bis(2,4-dinitrophenoxy)naphthalene is 61.3%.

Embodiment 3

[0032] 16.0 grams (0.10 moles) of 2,7-naphthalenediol, 40.5 grams (0.20 moles) of 2,4-dinitrochlorobenzene, 10.6 grams (0.10 moles) of sodium carbonate, 80 milliliters of N-methyl-2- Pyrrolidone and 30 milliliters of dichlorobenzene were put into the reaction kettle, stirred, heated to reflux and separated from water for 16 hours, concentrated the reaction solution, recovered the solvent for recycling, cooled the reactant system, added water, precipitated a solid product, washed, dried, Obtain 38.0 grams of 2,7-bis(2,4-dinitrophenoxy)naphthalene crystal product with a purity of 97.9%, according to the actual obtained 2,7-bis(2,4-dinitrophenoxy) The amount of naphthalene and the theoretical yield (49.2 g), the calculated yield of 2,7-bis(2,4-dinitrophenoxy)naphthalene was 77.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com