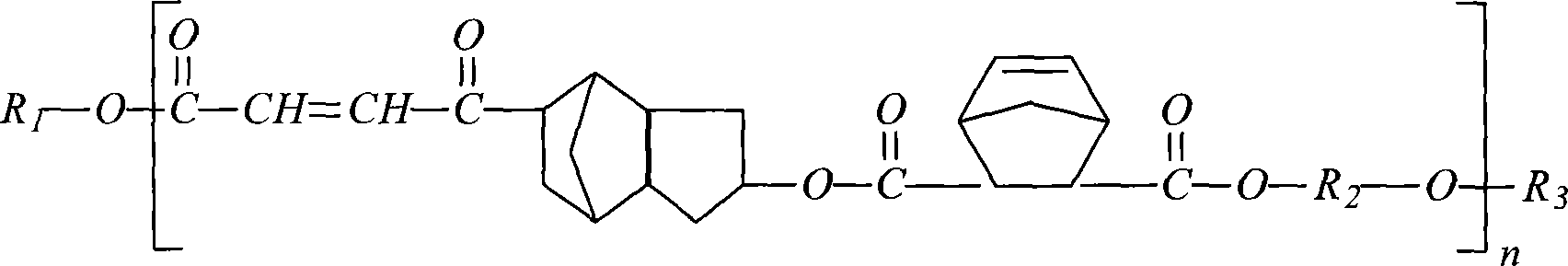

Method for preparing thickenable dicyclopentadiene unsaturated polyester resin

A technology of dicyclopentadiene and polyester resin, which is applied in the field of preparation of polymer compounds, can solve the problems of inability to meet the use requirements of unsaturated polyester molding compounds, poor thickening properties, etc., and achieves easy industrial expansion of production, low cost, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

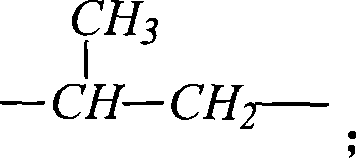

Embodiment 1

[0032] A kind of preparation method that can thicken dicyclopentadiene type unsaturated polyester resin is in the 1000mL four-necked flask that is equipped with stirrer, thermometer, reflux condenser, dropping funnel, adds 150g (1.530mol) cis-butyl Dicyclopentadiene, 27.5g (1.530mol) deionized water, start stirring, heat up to 100°C-140°C and keep it for 1h for hydrolysis reaction; add 130g (0.902mol) dicyclopentadiene dropwise at 110°C-180°C, add dropwise Time 1h; dropwise reaction at this temperature for 1h; add 45g (0.789mol) ethylene glycol, catalyst sodium acetate 0.25g (0.00305mol), polymerization inhibitor p-benzoquinone 0.12g (0.00111mol), and gradually increase the temperature Carry out dehydration polycondensation reaction at 200℃~210℃; when the acid value of the reactant reaches 65mgKOH / g, vacuum dehydration; when the acid value of the reactant reaches 30mgKOH / g~35mgKOH / g, release the vacuum and cool down; when the temperature of the reactant drops When the temperat...

Embodiment 2

[0034] The addition of dicyclopentadiene is increased to 176g (1.224mol), the addition of ethylene glycol is reduced to 28g (0.459mol), and the others are the same as in Example 1 (omitted). The viscosity of the product is 1075mPa·s (25°C), the gel time is 2.8min (126°C), and the acid value is 19.7mgKOH / g. After the resin thickening test, the viscosity of the resin paste increased to 9700Pa·s (25°C).

Embodiment 3

[0036] Dicyclopentadiene add-on is reduced to 88g (0.612), ethylene glycol add-on increases to 66g (1.071mol), other is the same as embodiment 1 (omitted). The viscosity of the product is 1138mPa·s (25°C), the gel time is 3.4min (126°C), and the acid value is 22.3mgKOH / g. After the resin thickening test, the viscosity of the resin paste increased to 11800Pa·s (25°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com