Garbage percolate treatment technique

A technology for landfill leachate and treatment process, applied in the field of landfill leachate treatment technology, can solve the problems of high leachate treatment cost, high treatment cost, application limitation, etc., achieve great practical value and social value, optimize process parameters, and treat cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

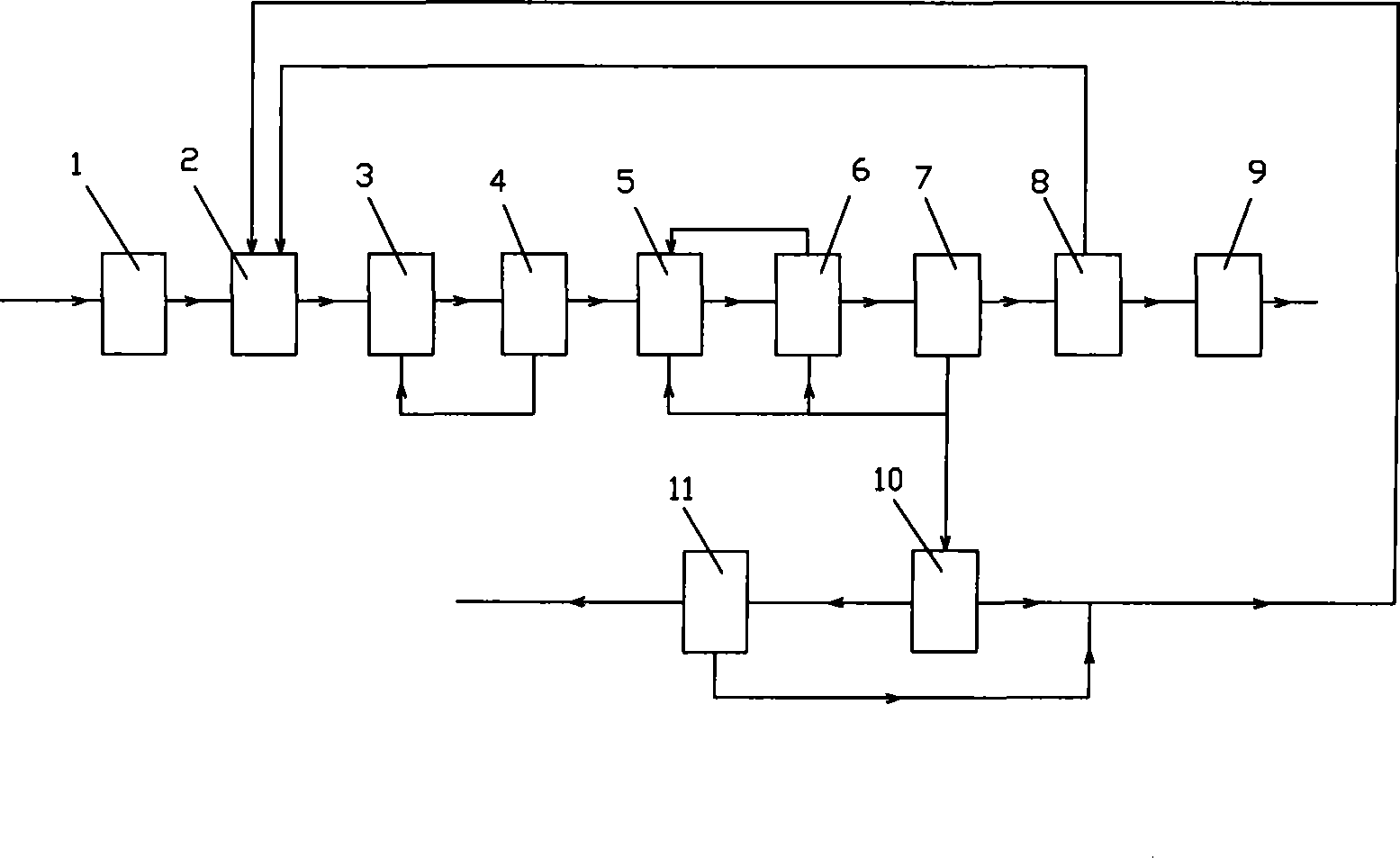

[0040] The present invention has been successfully applied to the treatment of waste seepage in Chongqing Tongxing Waste Incineration Power Plant. As shown in the figure, when the process of the present invention is implemented, the whole system mainly includes a grit chamber 1, a regulating pond 2, a UASB reactor 3, Intermediate tank 4, facultative tank 5, aeration tank 6, sedimentation tank 7, ultrafiltration membrane treatment system 8, reverse osmosis membrane treatment system 9, sludge thickening tank 10 and centrifugal sludge dehydrator 11. A heat exchanger is arranged between the adjustment tank 2 and the UASB reactor 3, and the water outlet of the adjustment tank 2 is pumped into the UASB reactor 3 by a water pump before the heat exchanger is heated by steam to keep the temperature of the water in the UASB reactor at 35°C. A heat exchange system is also provided between the intermediate pool 4 and the aerobic pool 5, and the outlet water of the intermediate pool 4 is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com