Technique for producing 2,5-dimethyl-2,5-hexandiol by extraction and decompression distillation method

A dimethyl and distillation technology, applied in 2 fields, can solve problems such as product whiteness and content not up to standard, small-scale manufacturers, and weak competitiveness of enterprises, so as to solve health and environmental protection problems, production Low cost and improved production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

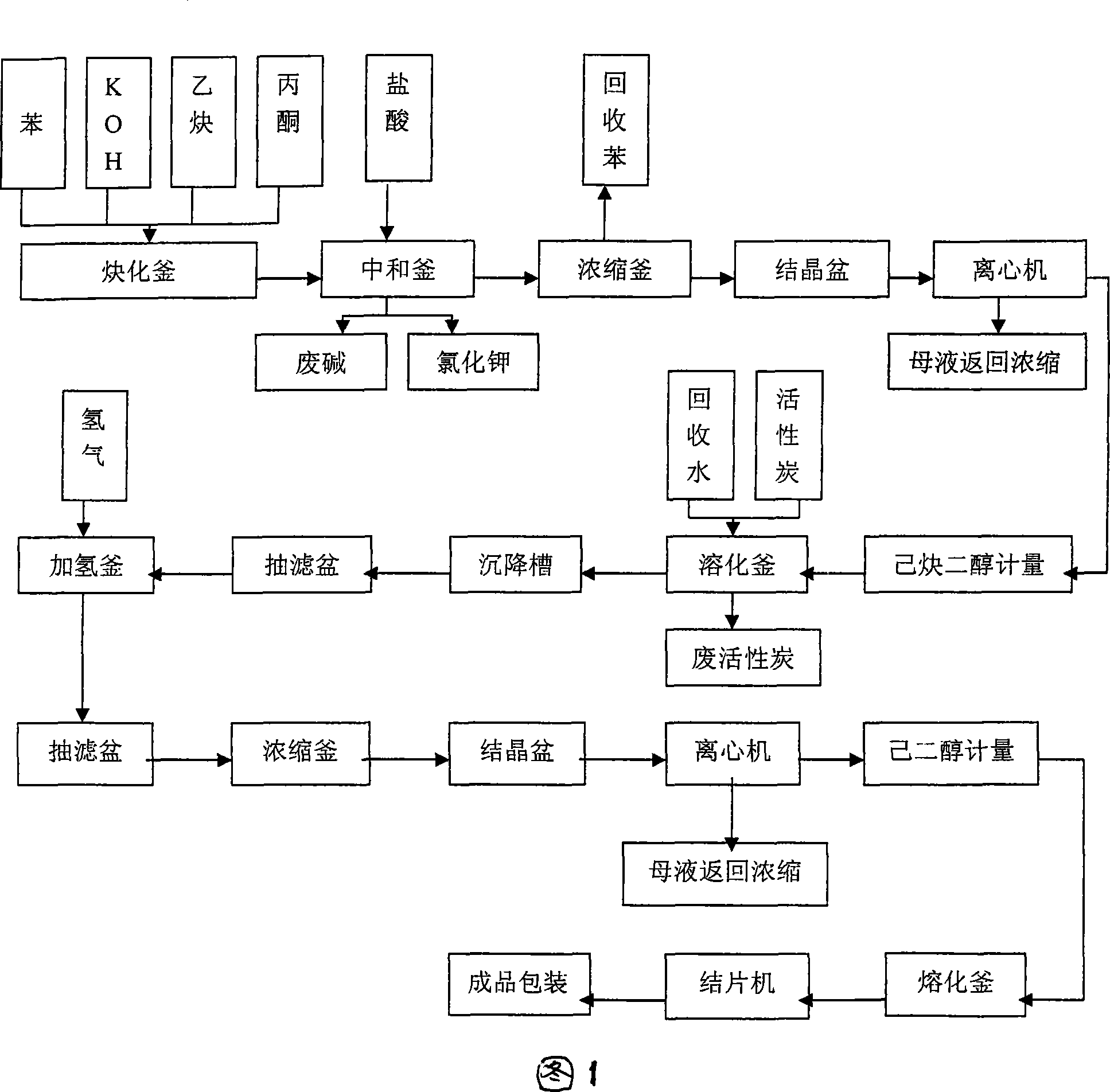

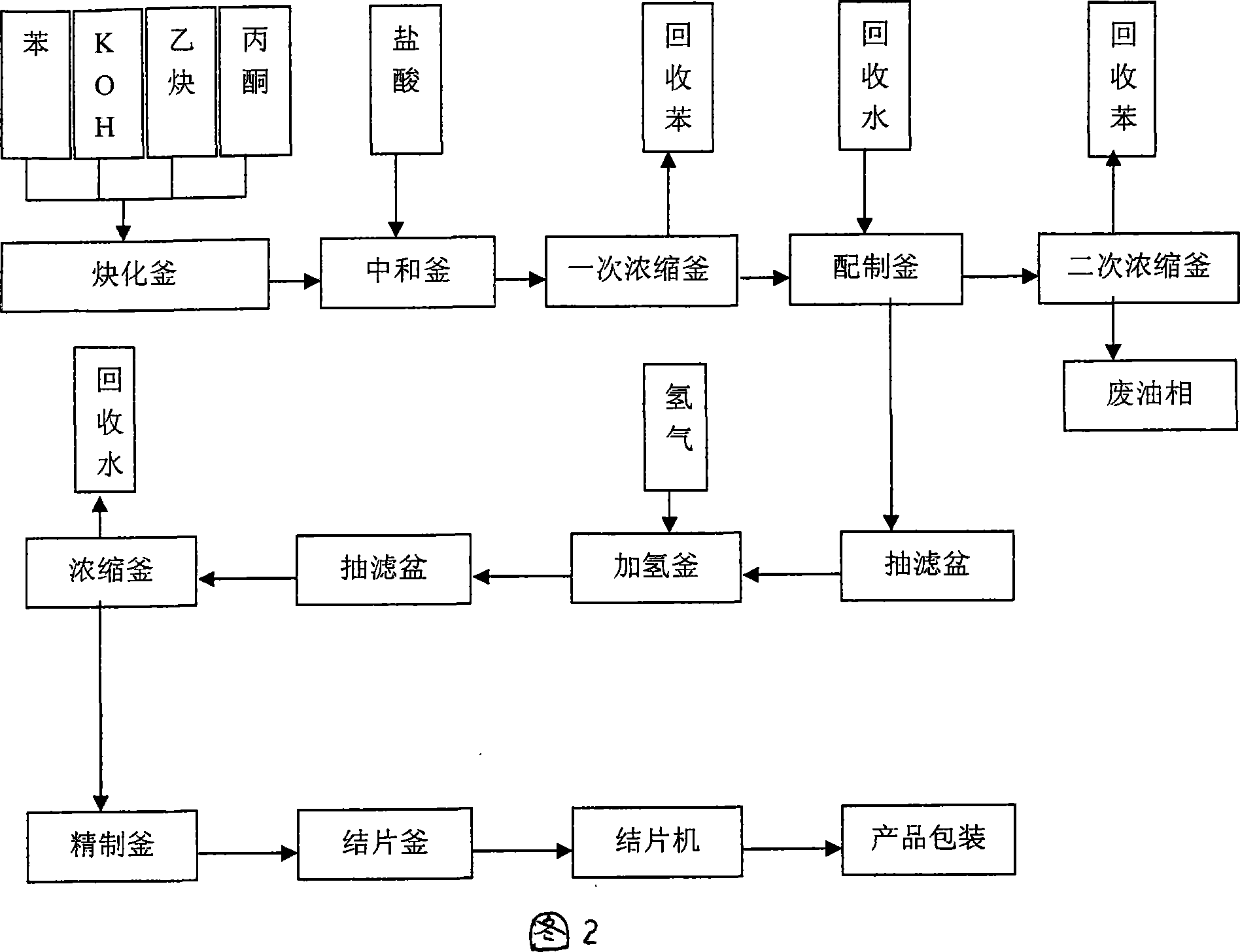

[0024] A kind of extraction and underpressure distillation method of the present invention produces 2,5-dimethyl-2, the new technology of 5-hexanediol, carry out according to the following steps: a), acetylene reaction and neutralization reaction: acetylene and acetone in benzene Condensate with potassium hydroxide in a solvent, and then neutralize with hydrochloric acid to obtain a feed solution containing 2,5-dimethyl-3-hexyne-2,5-diol (hereinafter referred to as acetylene diol) and oil phase and benzene The specific operation process is: first add pure benzene and potassium hydroxide for stirring, then replace with nitrogen and then add acetylene for 20-40 minutes, the gauge pressure on the kettle is controlled at 0.02-0.04MPa, the temperature of the kettle is 47-53°C, and then Add acetone dropwise, control the acetone feeding time to 4-4.5 hours, control the reaction temperature at 49-56°C, stop adding acetone and keep the pressure for 2 hours, add water to wash for 1 hour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com