Preparation of modified tailings powder and method for using the same as polymer filling material

A technology of tailings powder and modification, applied in the direction of dyeing organosilicon compound treatment, dyeing physical treatment, etc., to solve the problem of environmental pollution, easy to obtain, and realize the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

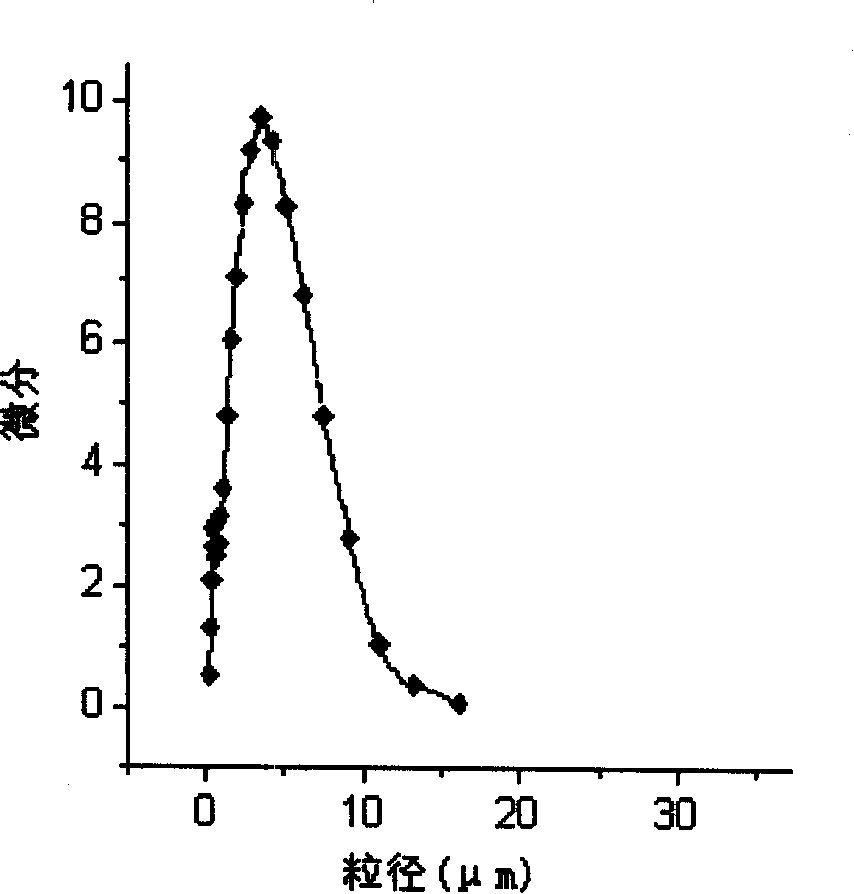

[0019] Example 1: Put 2 kg of tailings in a wet stirring mill, the ball milling medium adopts alumina balls, single-stage ball milling, the diameter is 4mm, the mass ratio of balls to material is 4:1, the ratio of material to water is 1:2, and the filling rate is 40%, the mill speed is 120r / min, and the grinding time is 2.5 hours. The slurry after grinding is press-filtered, dried and pulverized to obtain d 90 Ultrafine powder in the range of 15-20μm. Then put the powder in a self-made heatable high-speed stirring modifier, heat it up to 100°C, stir at a high speed of 800r / min for 30 minutes, and use the prepared mixed modifier, wherein, Absolute ethanol: silane modifier: titanate modifier = 2:1:1, the addition amount of silane modifier and titanate modifier is 3‰ of powder weight respectively, in the form of injection or spray Slowly inject into the modified cylinder, the injection time is 20min. After the injection is completed, increase the speed of the modifier to 1200r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com