Positive material rock salt Mn lithium of nano lithium ion battery and its making method

A technology for lithium-ion batteries and positive electrode materials, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of environmental pollution, safety, high price, and low specific capacity, and achieve good safety, low price, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

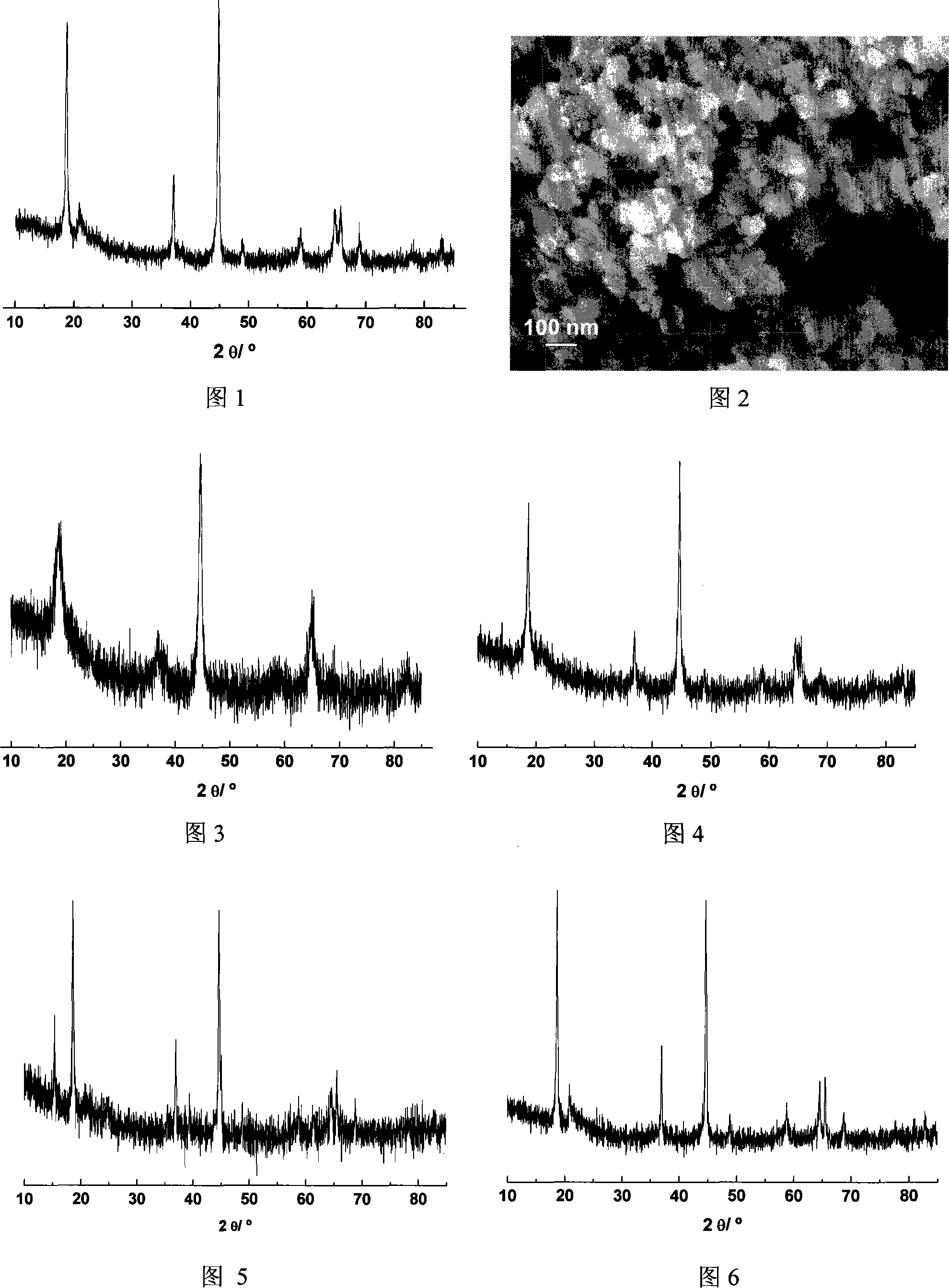

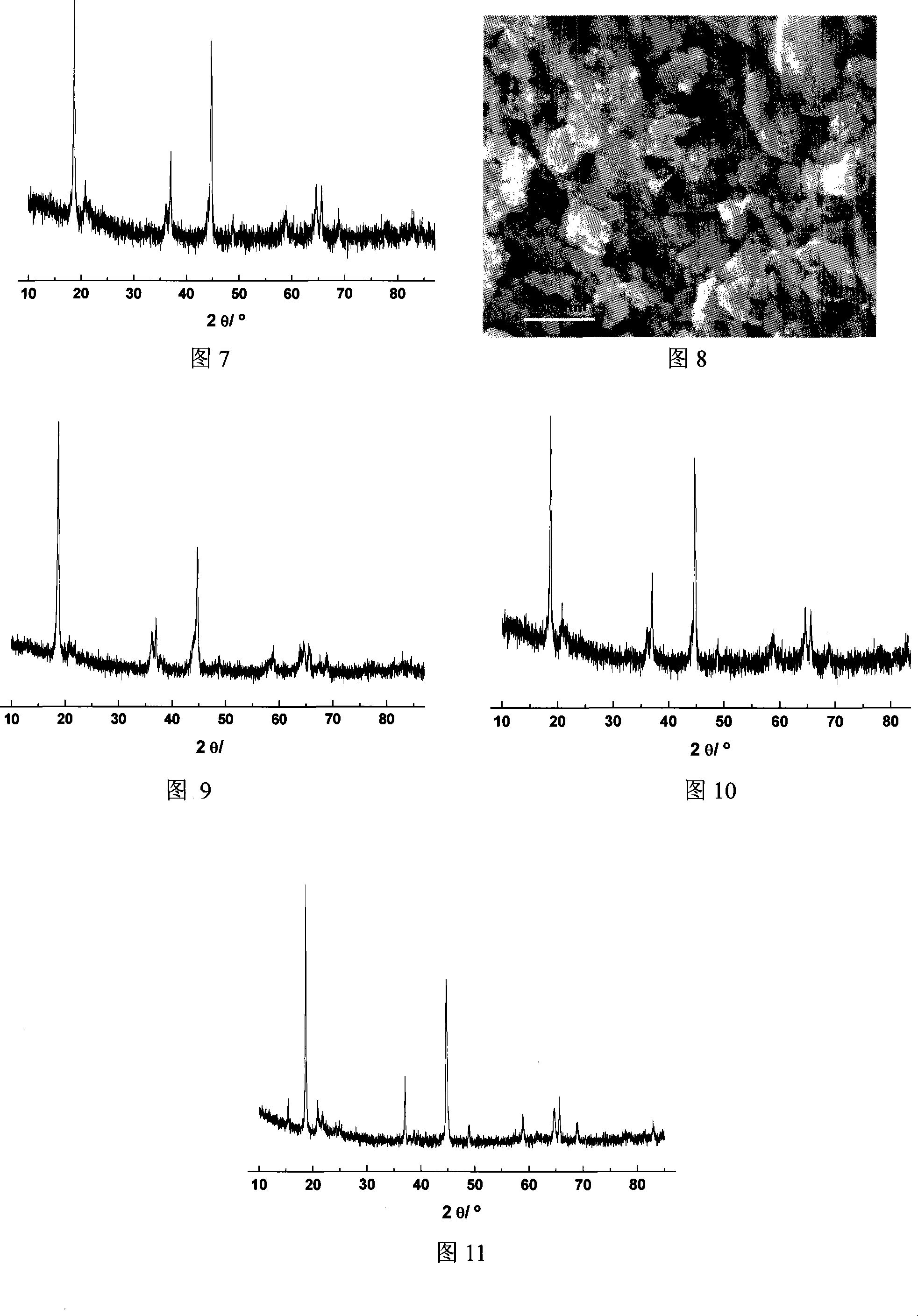

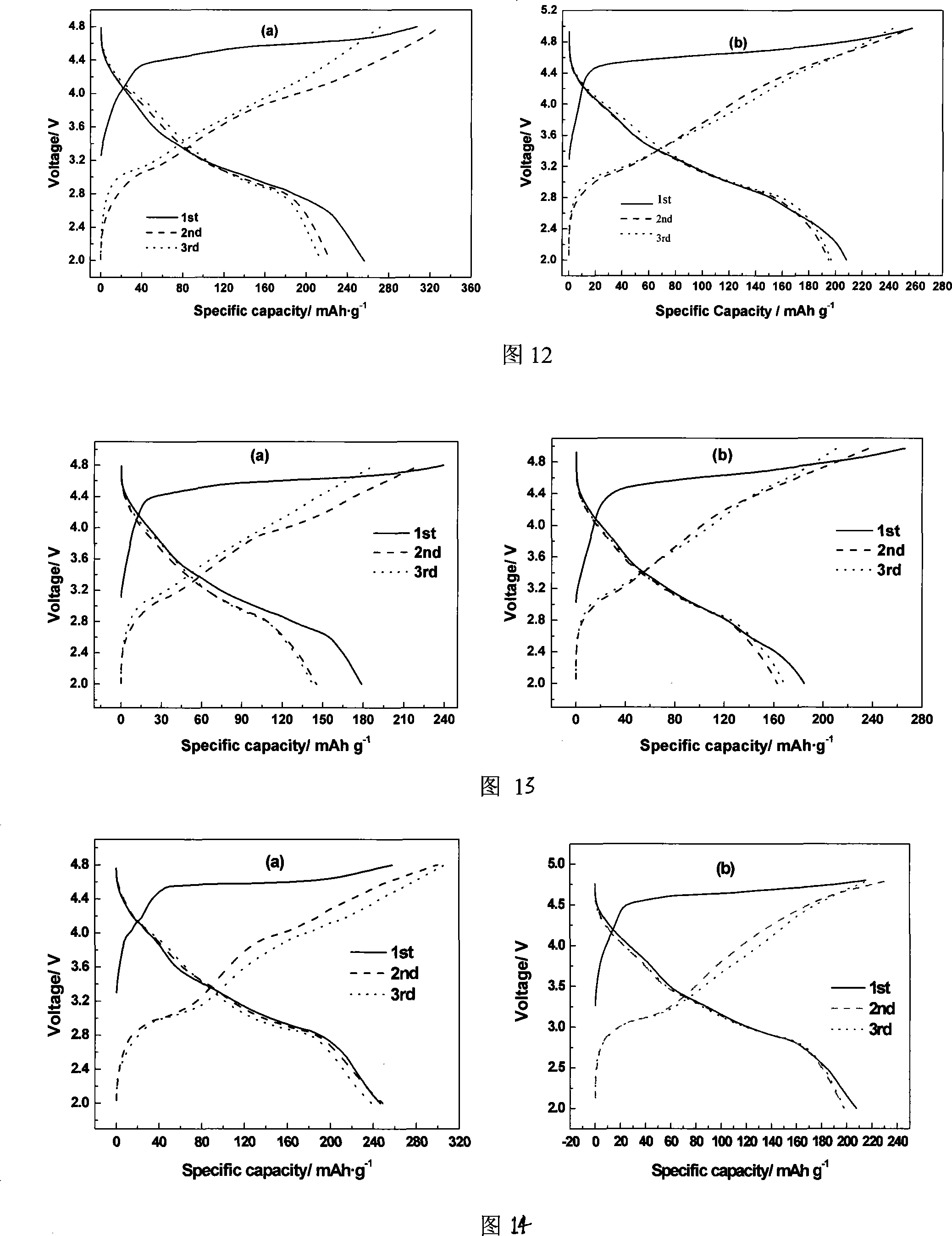

[0027] Embodiment 1: 7.6g manganese sulfate hexahydrate (MnSO 4 ·6H 2 O) was dissolved in 100mL deionized water, and poured into 120mL 0.03mol / L potassium permanganate (KMnO 4 ) aqueous solution, stirred and reacted for 2 hours, filtered and washed until neutral, and dried at 120° C. for 12 hours to obtain a precursor. Weigh 1.0g of the precursor, pour it into a solution containing 1.0mol / L lithium hydroxide (LiOH) and 0.05mol / L ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) in a hydrothermal kettle, after treatment at 180°C for 24h, the resulting precipitate was filtered and washed to neutral and dried at 120°C for 24h to obtain the lithium ion cathode material Li 2 MnO 3 (See Figure 1). Its particle size is 10-150nm (see Figure 2). According to the positive electrode material: acetylene black: binder = 80:10:10 (mass ratio), ball milling and mixing, coating on the treated aluminum foil, drying at 120 ° C, pressing and molding at 20 MPa to obtain Li 2 MnO 3 electrode.

Embodiment 2

[0028] Embodiment 2: 5.8g manganese chloride tetrahydrate (MnCl 2 4H 2 O) dissolved in 100mL deionized water, and poured into 120mL 0.03mol / L KMnO 4 In aqueous solution, with reference to embodiment 1, prepare lithium ion cathode material Li 2 MnO 3 . And prepare Li with reference to Example 1 2 MnO 3 electrode.

Embodiment 3

[0029] Embodiment 3: 3.4mL manganese nitrate aqueous solution (Mn(NO 3 ) 2 , 50wt%) was diluted in 100mL deionized water, and poured into 120mL 0.03mol / L KMnO 4 In aqueous solution, with reference to embodiment 1, prepare lithium ion cathode material Li 2 MnO 3 . And prepare Li with reference to Example 1 2 MnO 3 electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap