Production of nano-carbon tube

A technology of carbon nanotubes and ferrocene, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of carbon nanotube research in the ascendant, and achieve low cost, easy large-scale production, and easy control of conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve 0.05 g of bulk ferrocene in 5 mL of xylene.

[0024] (2) Add the solution obtained in step (1) into a quartz weighing bottle, and then put the weighing bottle into a hydrothermal reaction kettle.

[0025] (3) Put the reaction kettle into a box-type resistance furnace and heat to 600° C. to react for 18 minutes to obtain a black product, and take the black product out of a quartz weighing bottle to obtain carbon nanotubes.

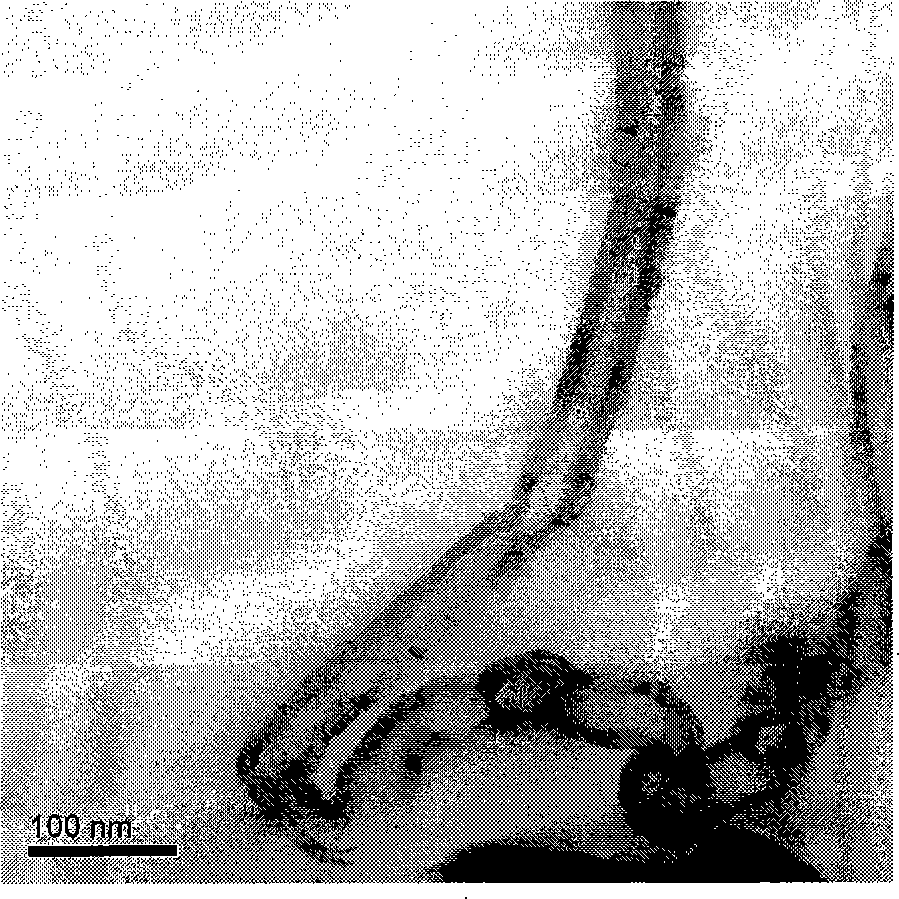

[0026] The product obtained in step (3) is characterized by its structure and morphology with SEM and TEM respectively, figure 1 The inner diameter of the carbon nanotubes obtained under this reaction condition is about 21 nm.

Embodiment 2

[0028] (1) Dissolve 0.05 g of bulk ferrocene in 5 mL of xylene.

[0029] (2) Add the solution obtained in step (1) into a quartz weighing bottle, and then put the weighing bottle into a hydrothermal reaction kettle.

[0030] (3) Put the reaction kettle into a box-type resistance furnace and heat it to 650° C. for 15 minutes to react to obtain a black product, and take the black product out of a quartz weighing bottle to obtain carbon nanotubes.

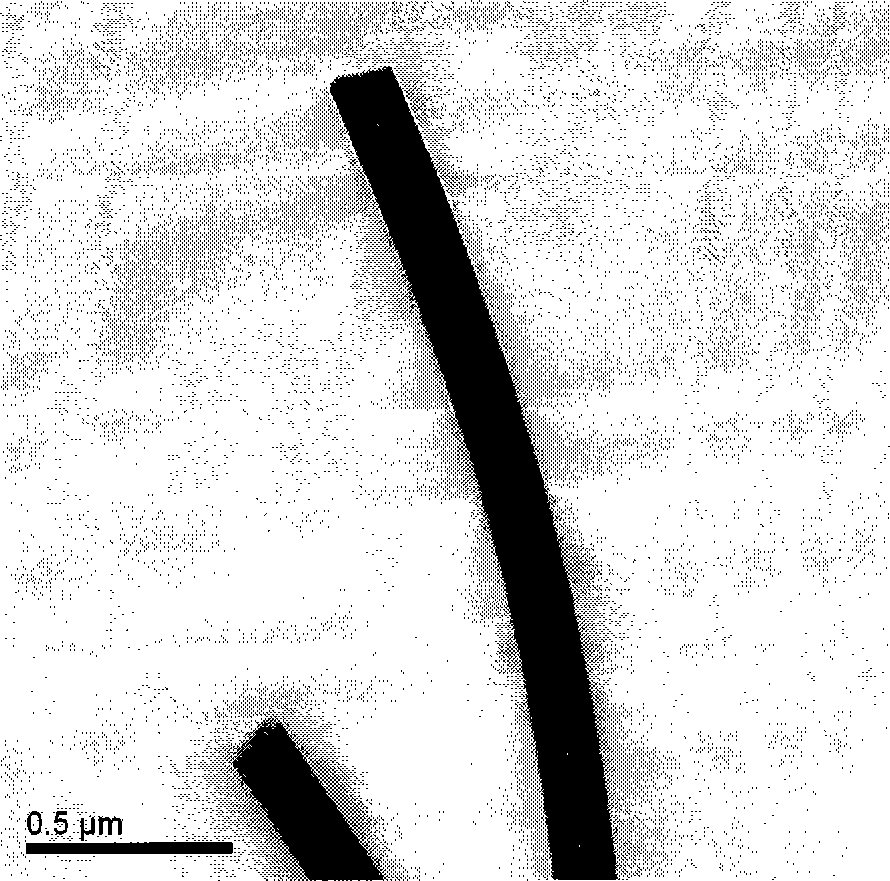

[0031] The structure and morphology of the product obtained in step (3) were characterized by SEM and TEM respectively, and the inner diameter of the obtained carbon nanotube was about 19 nm.

Embodiment 3

[0033] (1) Dissolve 0.05 g of bulk ferrocene in 5 mL of xylene.

[0034] (2) Add the solution obtained in step (1) into a quartz weighing bottle, and then put the weighing bottle into a hydrothermal reaction kettle.

[0035] (3) Put the reaction kettle into a box-type resistance furnace and heat to 700° C. for 15 minutes to react to obtain a black product, and take the black product out of a quartz weighing bottle to obtain carbon nanotubes.

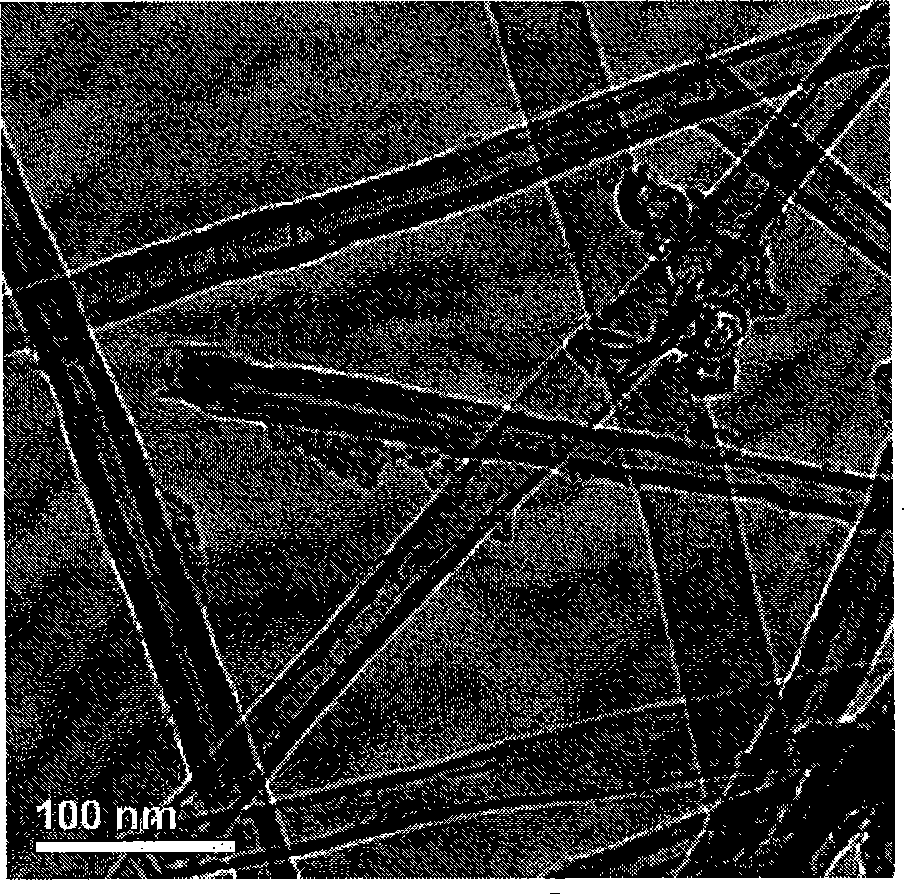

[0036] The product obtained in step (3) is characterized by its structure and morphology with SEM and TEM respectively, figure 2 The carbon nanotubes obtained under this reaction condition have an inner diameter of about 15 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com