Sulfalene oxazole molecular engram polymer producing method

A sulfamethoxazole and molecular imprinting technology is applied in the field of bioengineering to achieve the effects of overcoming serious impurity interference, shortening reaction time, and selecting and identifying excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

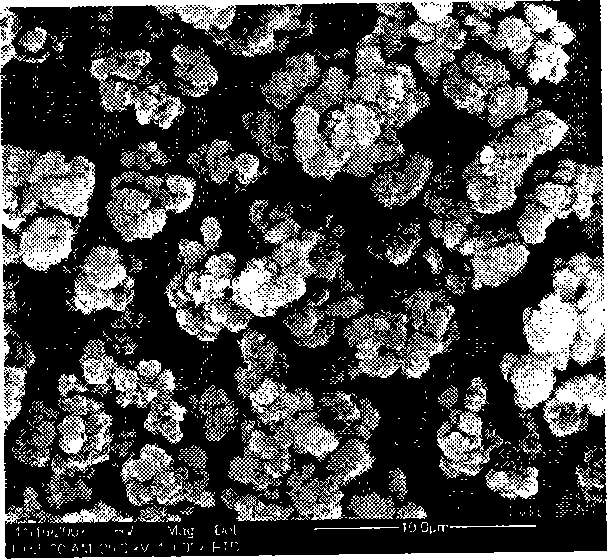

[0022] Weigh 0.25mmol template molecule sulfamethoxazole (SMO), 1mmol functional monomer methacrylic acid (MAA), and dissolve them in 2ml ionic liquid ([BMIM]BF 4 ) in an ampoule bottle, vibrate for 30min to make the template and functional monomer interact to form a complex, then add 5mmol of cross-linking agent ethylene glycol dimethacrylate (EDMA) and initiator azobisiso Butyronitrile (AIBN) 12mg, and mol ratio is SMO: MAA: EDMA=1: 4: 20, the ratio of the volume consumption of porogen and the molar weight of template molecule sulfamethoxazole is 8ml / mmol; After mixing, The molecularly imprinted solution was ultrasonically degassed, sonicated for 10 minutes, nitrogen gas was introduced for 10 minutes to deoxygenate, and finally the ampoule was vacuum-sealed, and then the ampoule was sealed under vacuum and reacted in a water bath at 60°C for 10 hours.

[0023] The resulting polymer was ground and sieved, and the polymer with a particle size of 40 μm-54 μm was screened out, a...

Embodiment 2

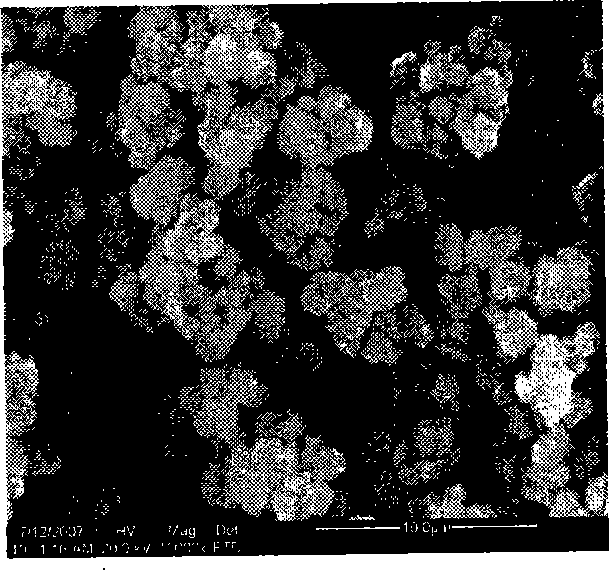

[0025] Weigh 0.25mmol template molecule sulfamethoxazole (SMO), 1mmol functional monomer methacrylic acid (MAA), dissolve them in 3ml ionic liquid ([BMIM]BF 4 ) in an ampoule bottle, vibrate for 30min to make the template and functional monomer interact to form a complex, then add 5mmol of cross-linking agent ethylene glycol dimethacrylate (EDMA) and initiator azobisiso Butyronitrile (AIBN) 12mg, and mol ratio is SMO: MAA: EDMA=1: 4: 20, the ratio of the volume consumption of porogen and the molar weight of template molecule sulfamethoxazole is 12ml / mmol; After mixing, The molecularly imprinted solution was ultrasonically degassed, sonicated for 10 minutes, nitrogen gas was introduced for 10 minutes to deoxygenate, and finally the ampoule was vacuum-sealed, and then the ampoule was sealed under vacuum and reacted in a water bath at 60°C for 10 hours.

[0026] The resulting polymer was ground and sieved, and the polymer with a particle size of 40 μm-54 μm was screened out, and ...

Embodiment 3

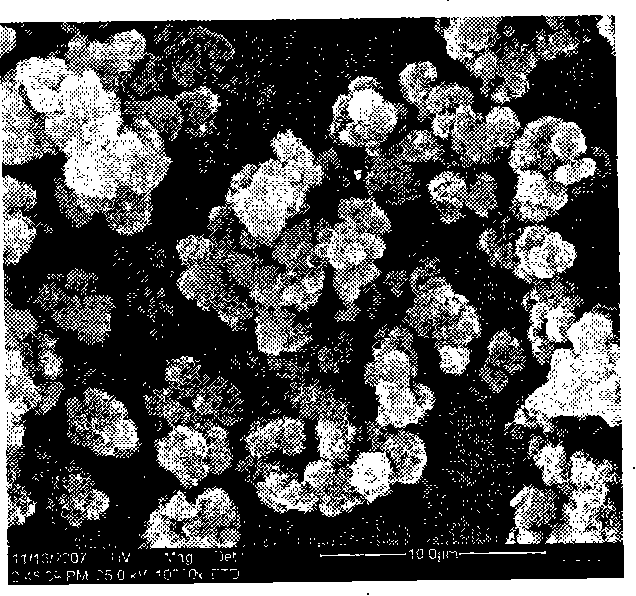

[0028] Weigh 0.25mmol template molecule sulfamethoxazole (SMO), 1mmol functional monomer methacrylic acid (MAA), dissolve them in 4ml ionic liquid ([BMIM]BF 4) in an ampoule bottle, vibrate for 30min to make template and functional monomer interact to form a complex, then add 5mmol crosslinking agent ethylene glycol dimethacrylate (EDMA) and initiator azobisiso Butyronitrile (AIBN) 12mg, and mol ratio is SMO: MAA: EDMA=1: 4: 20, the ratio of the volume consumption of porogen and the molar weight of template molecule sulfamethoxazole is 16ml / mmol; After mixing, The molecularly imprinted solution was ultrasonically degassed, sonicated for 10 minutes, nitrogen gas was introduced for 10 minutes to deoxygenate, and finally the ampoule was vacuum-sealed, and then the ampoule was sealed under vacuum and reacted in a water bath at 60°C for 10 hours.

[0029] The resulting polymer was ground and sieved, and polymers with a particle size of 40 μm-54 μm were sieved to elute the template ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com