Etherification method for producing clean gasoline

A technology of etherification and gasoline, which is applied in cracking, petroleum industry, catalytic cracking, etc. It can solve the problems of complex process and many process steps, and achieve the effect of increasing octane number, multi-operation flexibility and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

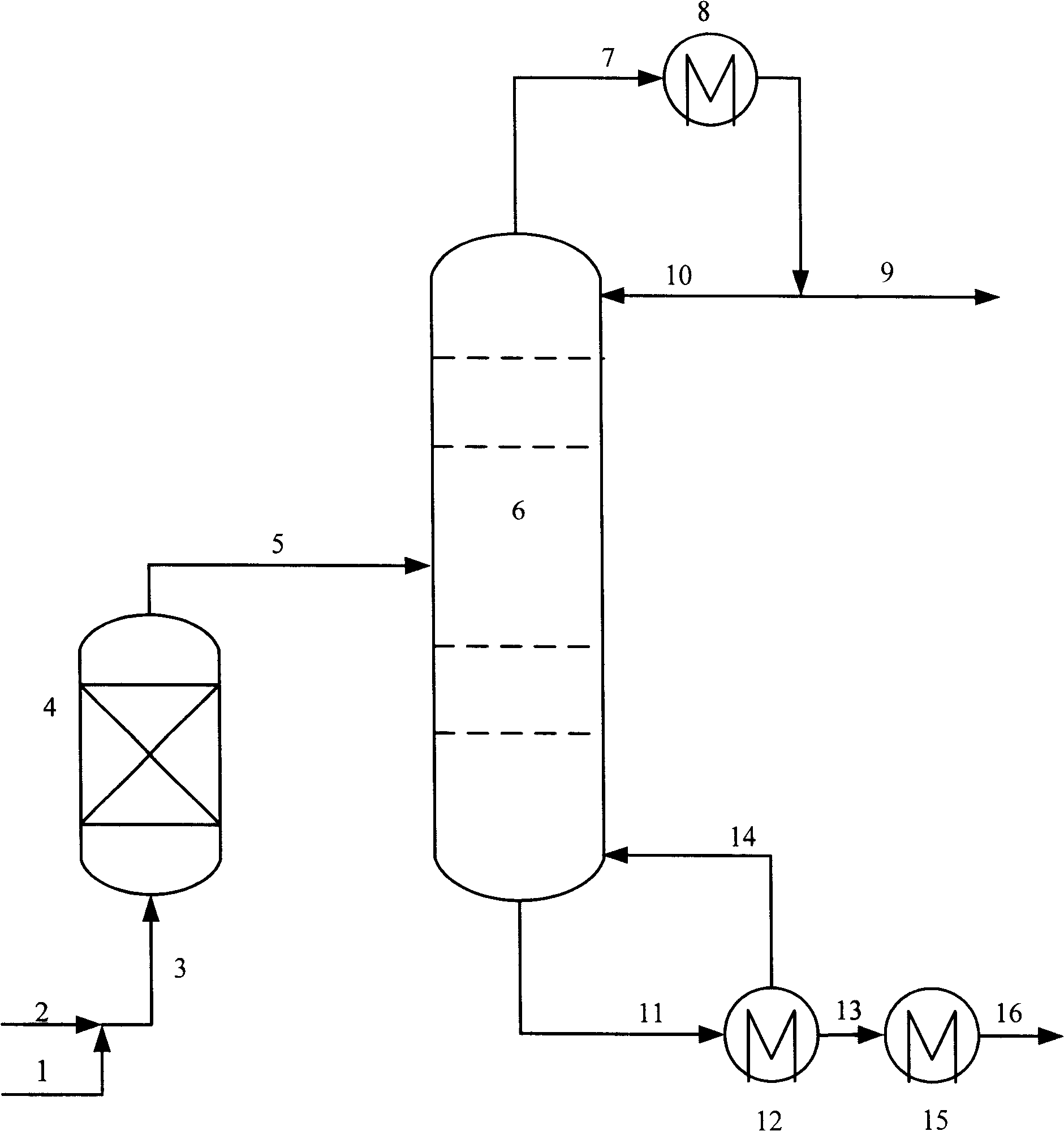

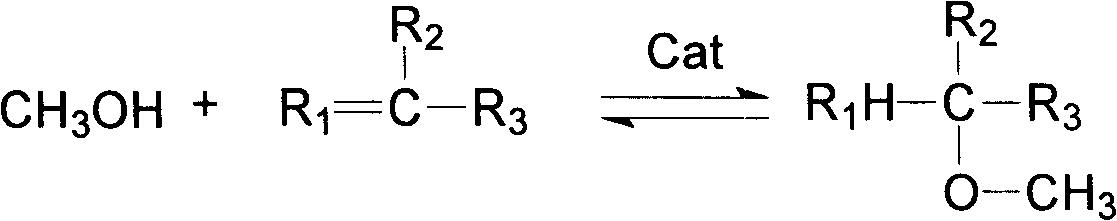

Method used

Image

Examples

Embodiment 1

[0034] The hydrocarbon etherification raw material that present embodiment adopts is the C that contains 20% isobutene 4 Fraction, C 4 The distillate is mixed with methanol and enters the etherification reactor, where it contacts and reacts with etherification catalyst A, and the reaction product enters the stabilizing tower for fractionation, and the gas component is obtained from the top of the stabilizing tower, and MTBE is obtained at the bottom of the stabilizing tower. The etherification reaction conditions are: the alcohol / ene mass ratio is 0.5, the reaction temperature is 120°C, and the reaction pressure is 1.5MPa. 4 Distillate meter, the weight space velocity of feed liquid is 2.0h -1 , the operating conditions of the stable tower are: tower top temperature 40°C, tower bottom temperature 140°C, tower pressure 1.5MPa, tower top reflux ratio 5, the reaction result is methanol conversion 100%, and MTBE selectivity > 99%.

Embodiment 2

[0038] The hydrocarbon etherification raw material used in this example is the same catalytic cracking deethanized gasoline 1 as that of Comparative Example 1. After being mixed with methanol, the catalytic cracked deethanized gasoline 1 enters the etherification reactor and contacts with the catalytic cracking catalyst GOR-II. reaction, the reaction product enters the stabilizing tower for fractional distillation, liquefied gas is obtained from the top of the stabilizing tower, and stable gasoline containing ether compounds is obtained at the bottom of the stabilizing tower. The etherification reaction conditions are: the alcohol / hydrocarbon mass ratio is 0.2, the reaction temperature is 100°C, the reaction pressure is 1.7MPa, and the weight space velocity of the feed liquid is 2.0h in terms of deethanized gasoline -1 , the operating conditions of the stable tower are: tower top temperature 50°C, tower bottom temperature 160°C, tower pressure 1.5MPa, tower top reflux ratio 5. ...

Embodiment 3

[0043] The hydrocarbon etherification raw material used in this example is the same catalytic cracking deethanized gasoline 2 as that of Comparative Example 2. After being mixed with methanol, the catalytic cracked deethanized gasoline 2 enters the etherification reactor and contacts with the catalytic cracking catalyst CGP-1 reaction, the reaction product enters the stabilizing tower for fractional distillation, liquefied gas is obtained from the top of the stabilizing tower, and stable gasoline containing ether compounds is obtained at the bottom of the stabilizing tower. The etherification reaction conditions are: the alcohol / hydrocarbon mass ratio is 0.3, the reaction temperature is 110°C, the reaction pressure is 1.7MPa, and the weight space velocity of the feed liquid is 6.0h in terms of deethanized gasoline -1 , the operating conditions of the stable tower are: tower top temperature 50°C, tower bottom temperature 170°C, tower pressure 1.7MPa, tower top reflux ratio 5.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com