Design method of high-temperature superconducting cable/busbar main body

A technology of high-temperature superconductivity and design method, which is applied in the field of power transmission and transformation of power systems, and can solve the problems of increased transmission AC loss and large attenuation of critical current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing and design method of the present invention will be further described:

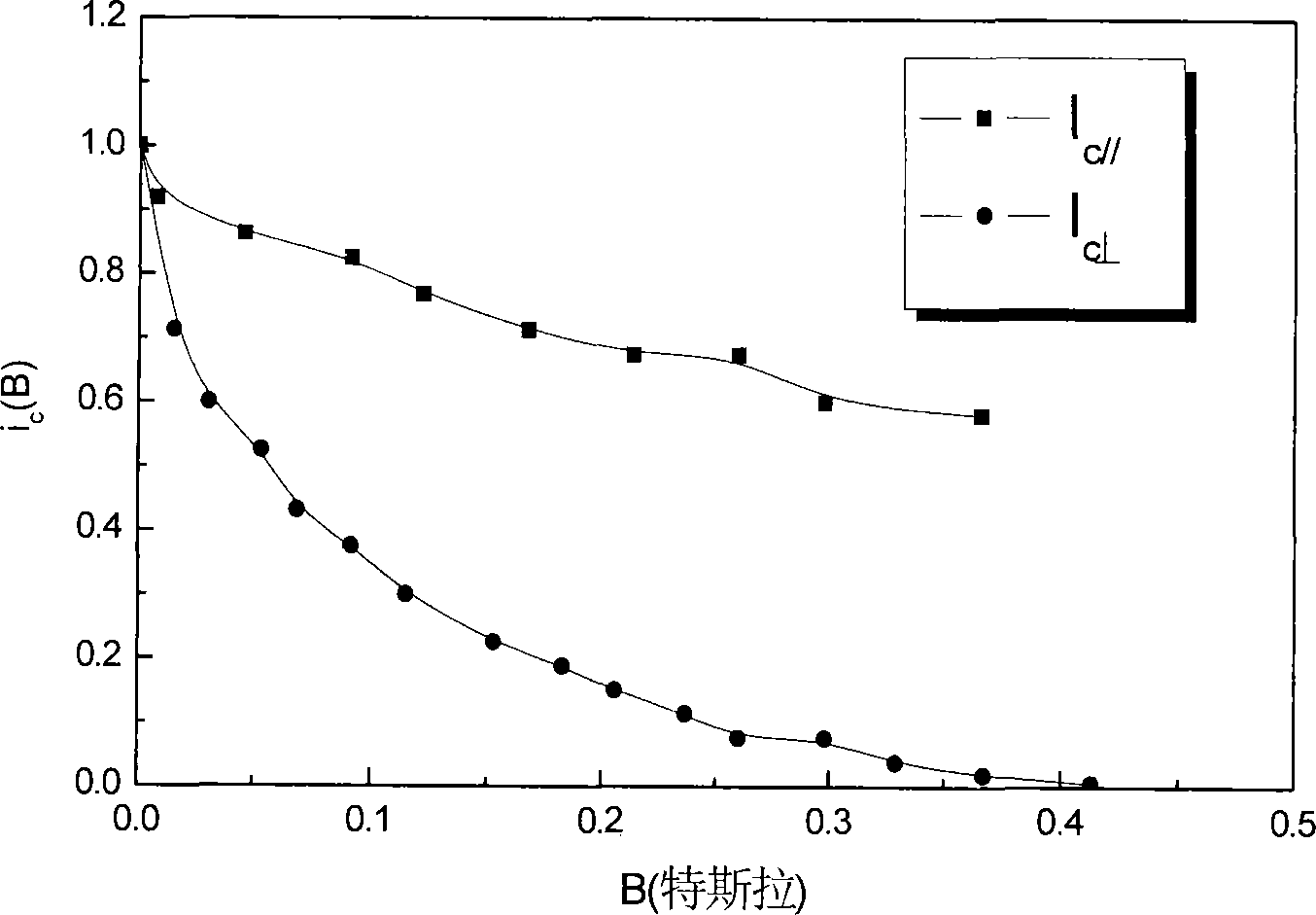

[0054] figure 1 Schematic diagram of the anisotropic characteristics of the critical current in the 77K temperature region of a typical high-temperature superconducting strip:

[0055] exist figure 1 Among them, the abscissa represents the field strength (unit: Tesla), the ordinate represents the normalized critical current, and i c∥ and i c⊥ are the normalized critical currents of superconducting wires in parallel and perpendicular fields, respectively.

[0056] Such as figure 1 As shown, the critical current attenuation of the superconducting strip is small under the parallel field, but the critical current attenuation is serious under the vertical field.

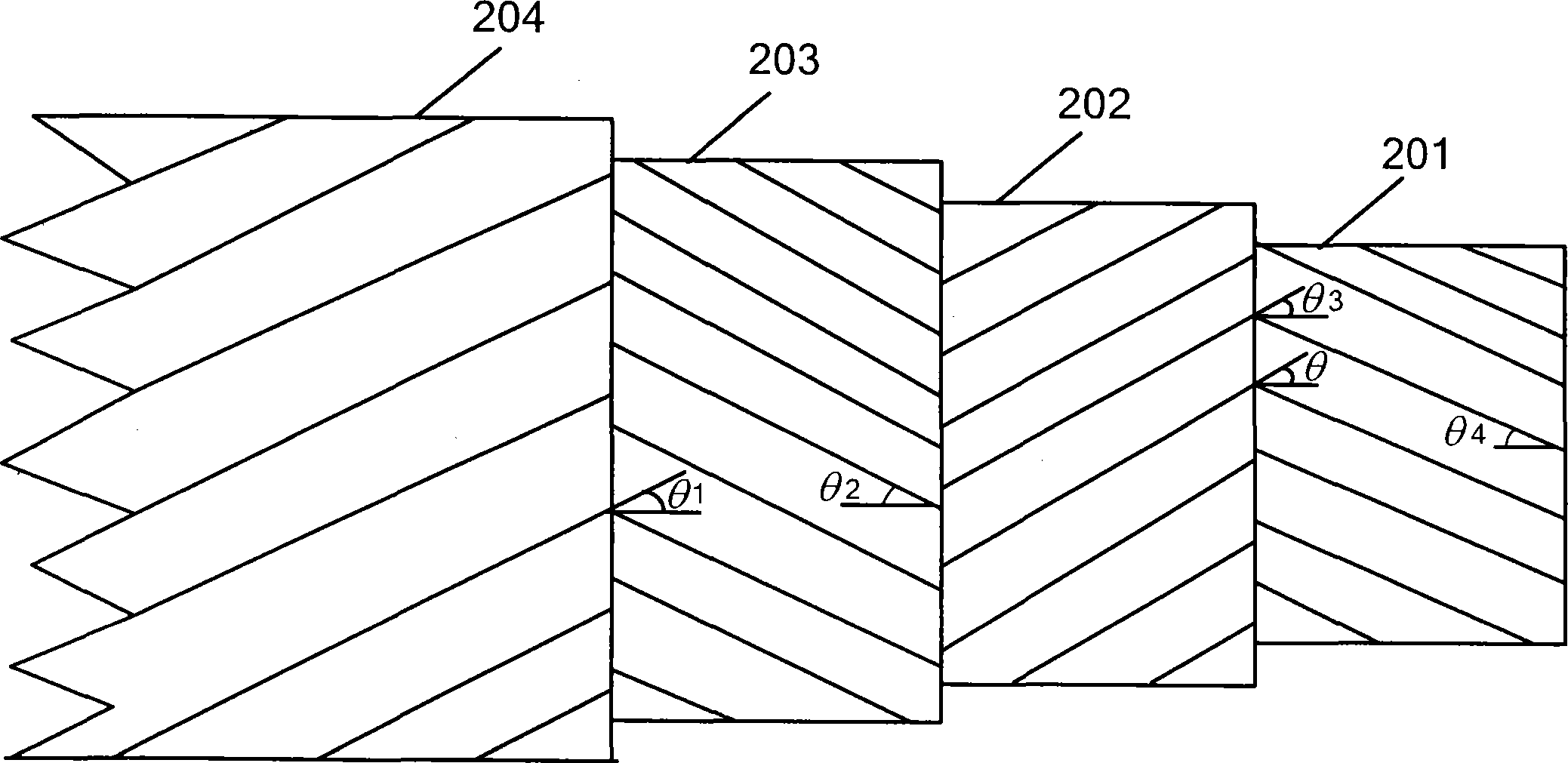

[0057] figure 2 Schematic diagram of a superconducting cable / busbar body wound for a four-layer superconducting tape:

[0058] exist figure 2 Among them, 201 represents the first layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com