Hollow fiber film, and preparation and use thereof

A production method, fiber membrane technology, applied in the field of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

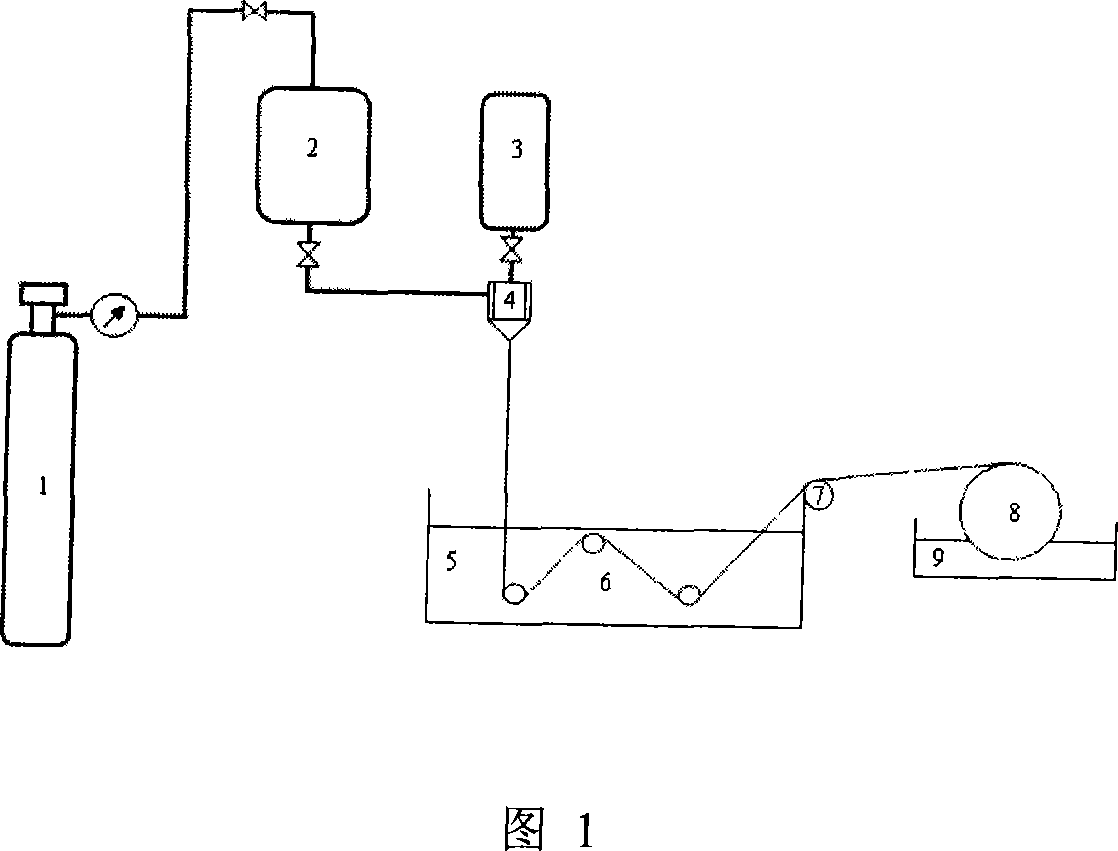

Method used

Image

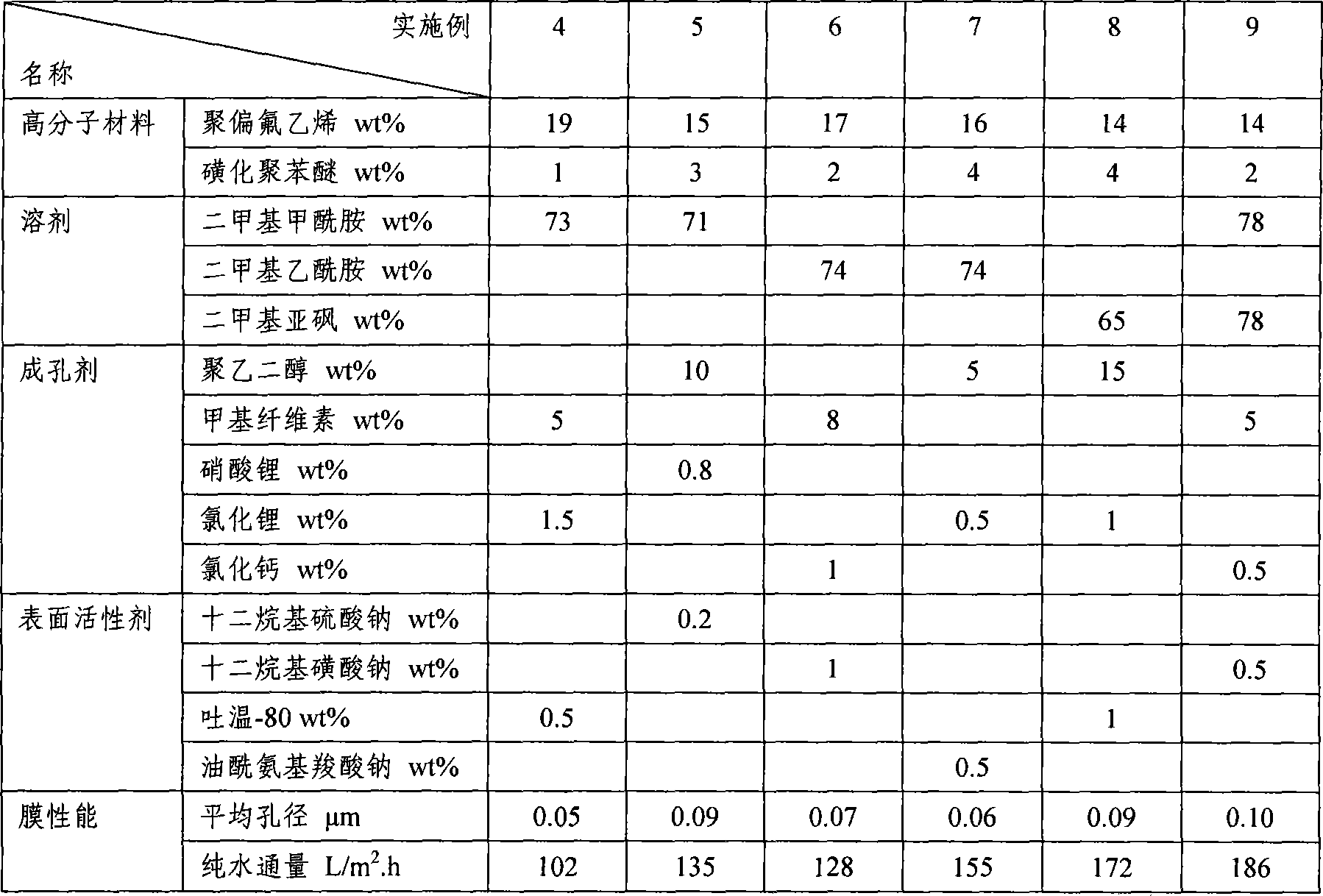

Examples

Embodiment 1

[0060] Dissolve 15 grams of polyvinylidene fluoride, 5 grams of sulfonated polyphenylene ether and 5 grams of polyethylene glycol in 40 grams, 15 grams and 10 grams of dimethylacetamide, respectively, at a dissolution temperature of 80 ° C, and then mix them Then, adopt the dry-wet spinning method, the dry spinning length is 6cm, the extrusion volume flow rate is 2mL / min, the spinning solution temperature is 60°C, and the core solution is 10% dimethylacetamide aqueous solution by weight. The coagulation bath uses deionized water, and the temperature of the coagulation bath is 50°C, so that the so-called blended hollow fiber membrane is obtained; its structure is a double-skin structure, and the pure water flux of the membrane is 120L / m 2 .h.bar, with an average pore size of 0.06 microns. The membrane is used for resource utilization of municipal sewage, and the effluent is reused as green reclaimed water. When the influent water quality is COD Cr 60mg / L, BOD 5 5mg / L, ammon...

Embodiment 2

[0068] Dissolve 13 g of polyvinylidene fluoride, 6 g of sulfonated polyphenylene ether, and 10 g of polyethylene glycol in 45 g, 16 g, and 10 g of dimethylacetamide, respectively, at a dissolution temperature of 80°C, and then mix them together , using the dry-wet spinning method, the dry spinning length is 6cm, the extrusion volume flow rate is 3mL / min, the spinning solution temperature is 80°C, the core solution is 20% dimethylacetamide aqueous solution by weight, and the coagulation bath Using deionized water, the temperature of the coagulation bath is 50°C, and the so-called blended hollow fiber membrane is obtained; its structure is a double-skin structure, and the pure water flux of the membrane is 160L / m 2 .h, with an average pore size of 0.08 microns. The membrane is used for domestic sewage treatment in office buildings, and the effluent is reused as regenerated water for cleaning and toilet flushing. When the influent water quality is COD Cr 58mg / L, BOD 5 7mg / L,...

Embodiment 3

[0070] Dissolve 17 g of polyvinylidene fluoride, 3 g of sulfonated polyphenylene ether, and 15 g of polyvinylpyrrolidone in 55 g, 15 g, and 5 g of dimethylacetamide, respectively, at a dissolution temperature of 80°C, and then mix them together , using the dry-wet spinning method, the dry spinning length is 4cm, the extrusion volume flow rate is 2.5mL / min, the temperature of the spinning solution is 80°C, and the core solution is a dimethylacetamide aqueous solution with a weight concentration of 15%. The bath uses deionized water, and the temperature of the coagulation bath is 45°C, that is, the so-called blended hollow fiber membrane is obtained; its structure is a double-skin structure, and the pure water flux of the membrane is 190L / m 2 .h, with an average pore size of 0.09 microns. The membrane is used for domestic sewage treatment in residential quarters, and the effluent is used as landscape water. When the influent water quality is COD Cr 72mg / L, BOD 5 9mg / L, ammo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com