Wheat puffing bran flour, preparation and applications thereof

A technology of wheat bran and bran powder, which is applied in application, food preparation, food science, etc., can solve the problems of restricting the application of food raw materials and short shelf life, achieve significant economic and social benefits, improve shelf life, and have a delicate taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 Bran puffing water addition experiment

[0047]Bran is difficult to puff because it is rich in fiber and low in starch content. By increasing the water content of bran, it is easy to puff. The amount of water added depends on whether the raw materials can smoothly exit the puffing cavity. The puffing adopts JYNPH80-22 puffing machine and conventional puffing process. The amount of water added and the puffing effect are shown in Table 2 (the amount of water added is the percentage by weight based on the weight of the raw material bran, and the moisture content of the expanded bran is the percentage by weight based on the weight of the expanded bran):

[0048] Table 2 Water content for bran puffing

[0049] project

Moisture of fine bran (%)

Amount of water added (%)

Moisture after puffing (%)

Puffing effect

1

11.20

8

12.00

generally

2

11.20

9

14.27

generally

3 ...

Embodiment 2

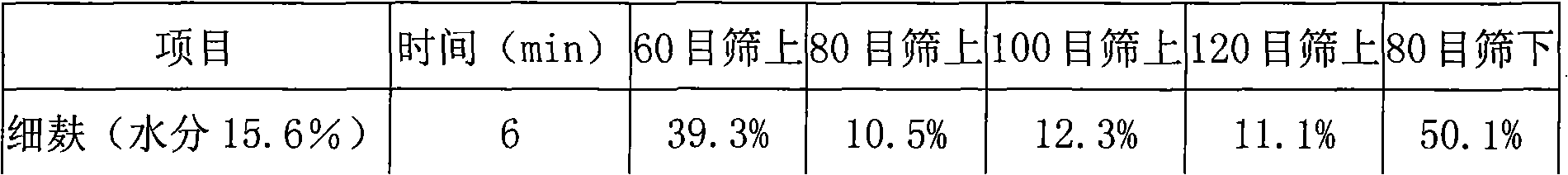

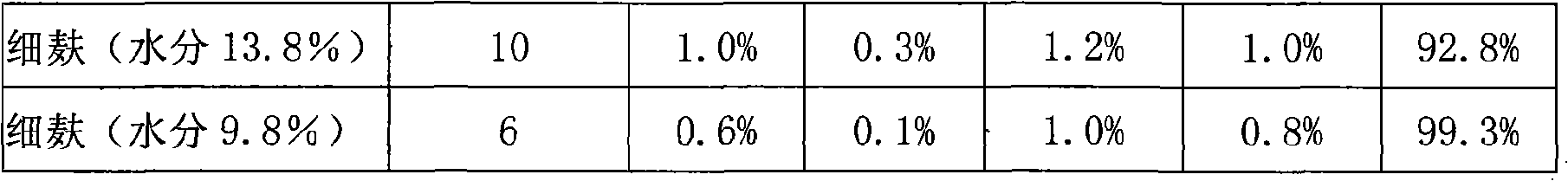

[0053] Embodiment 2 ultrafine pulverization process

[0054] Set the crushing temperature to -10°C, and analyze the particle size distribution of puffed bran with different moisture content. The results are shown in Table 4:

[0055] Table 3 Ultrafine pulverization of puffed fine bran

[0056]

[0057]

[0058] The results show that when the moisture content exceeds 14% after puffing, the crushing difficulty increases and the effect is not good. Analyzing the reason, it may be because the material has high humidity and strong toughness, which makes it difficult to crush. When the material is further dried to a moisture content of ≤10%, the material is crisp and the crushing effect is good.

[0059] Thus, it is determined that the optimum process condition for puffing fine bran is adding 10% water to puff the fine bran, drying the puffed product to a moisture content of 9-14%, ultrafine pulverization at -10°C for 6-10 minutes, and passing through an 80-mesh sieve.

Embodiment 3

[0060] The preparation of embodiment 3 whole wheat flour

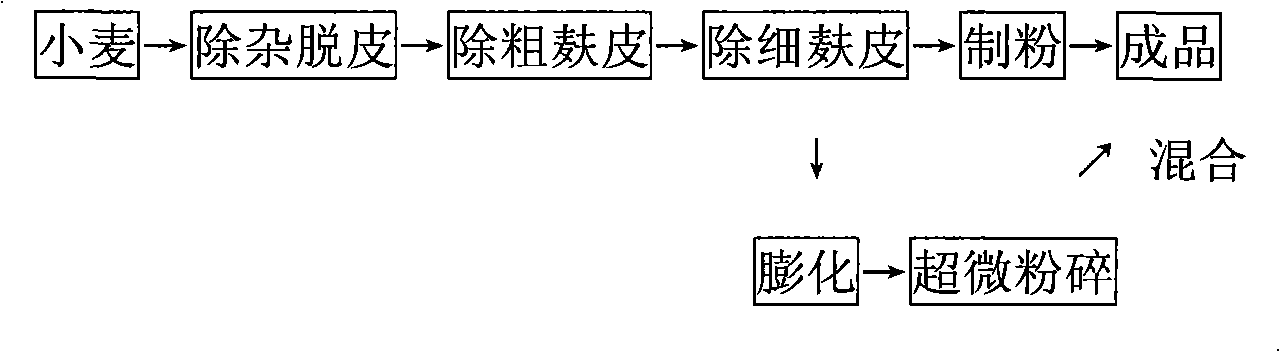

[0061] Whole wheat flour production process route see figure 1 .

[0062] In order to ensure the edibility of the whole wheat flour, the wheat is firstly processed to remove impurities, and then the cleaned wheat is peeled and sieved. In the production of whole wheat flour, wheat surface cleaning and tempering are important links. The efficiency of the cleaning process will directly affect the ash content and edibility of the product. Considering the palatability of bran, whole wheat flour is produced by removing the coarse bran, focusing on processing the fine bran, and adding it back into the flour.

[0063] The wheat puffed fine bran powder that adopts embodiment 2 optimum process conditions to obtain is mixed with flour (common flour not containing bran and wheat germ) and wheat germ powder (obtained after wheat germ superfine grinding) by following percentage by weight To make whole wheat flour:

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com