Method for preparing trichlorosilane and polycrystalline silicon by transforming silicon tetrachloride

A silicon tetrachloride and polycrystalline silicon technology, applied in the direction of halogenated silicon compounds, halogenated silanes, etc., can solve the problems of small equipment investment, low primary conversion rate, low energy consumption, etc., and achieve improved primary conversion rate, good economic benefits and The effect of social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Example: Using silicon tetrachloride as raw material, the main production is SiHCl 3 , a device system and a production method for co-producing polysilicon and by-producing HCl.

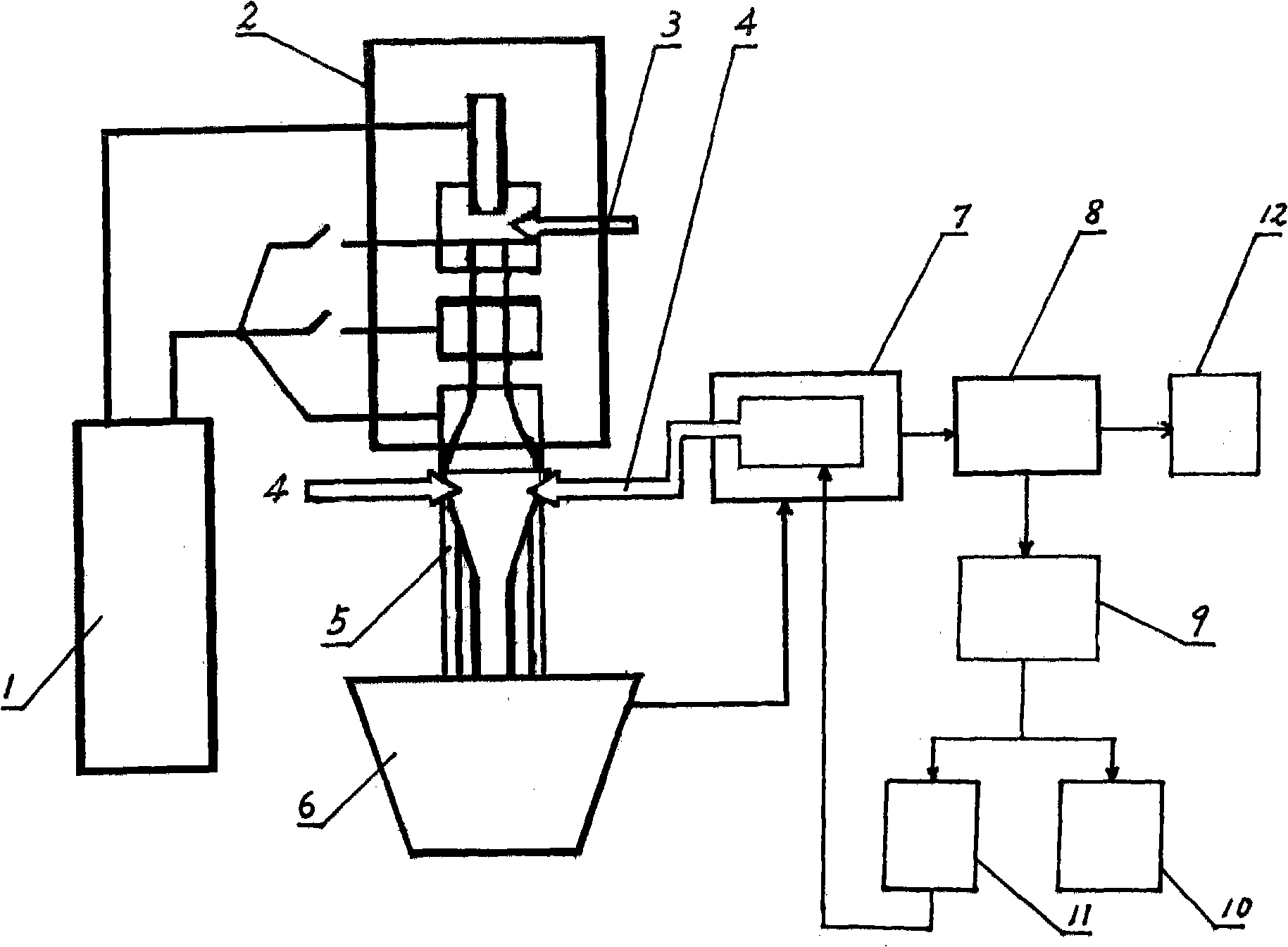

[0028] figure 1 An apparatus system for carrying out the method of the invention is presented. The device system is mainly composed of a plasma generator 2, a plasma power supply 1 providing electric energy for the plasma generator, a reactor 5 vertically arranged below the plasma generator 2, and a gas buffer vertically arranged below the reactor 5. Container 6, a waste heat exchanger 7 connected to the gas buffer vessel 6, a condenser 8 connected to the gas outlet pipe of the waste heat exchanger 7, a fractionation tower 9 connected to the condensed liquid outlet of the condenser 8, and a gas outlet pipe connected to the condenser 8 The tail gas separation system 12 that the outlet is connected is in order to separate and store hydrogen, argon and hydrogen chloride gas, the trichlorosilane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com