Method for producing lactic acid by using glycerol

A technology of glycerin and lactic acid, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effects of reducing production costs, saving costs, and broadening the range of choices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] (1) Fermentation method: 5L mechanical stirring fermentation tank, batch fermentation with air

[0016] (2) Bacteria: Escherichia coli

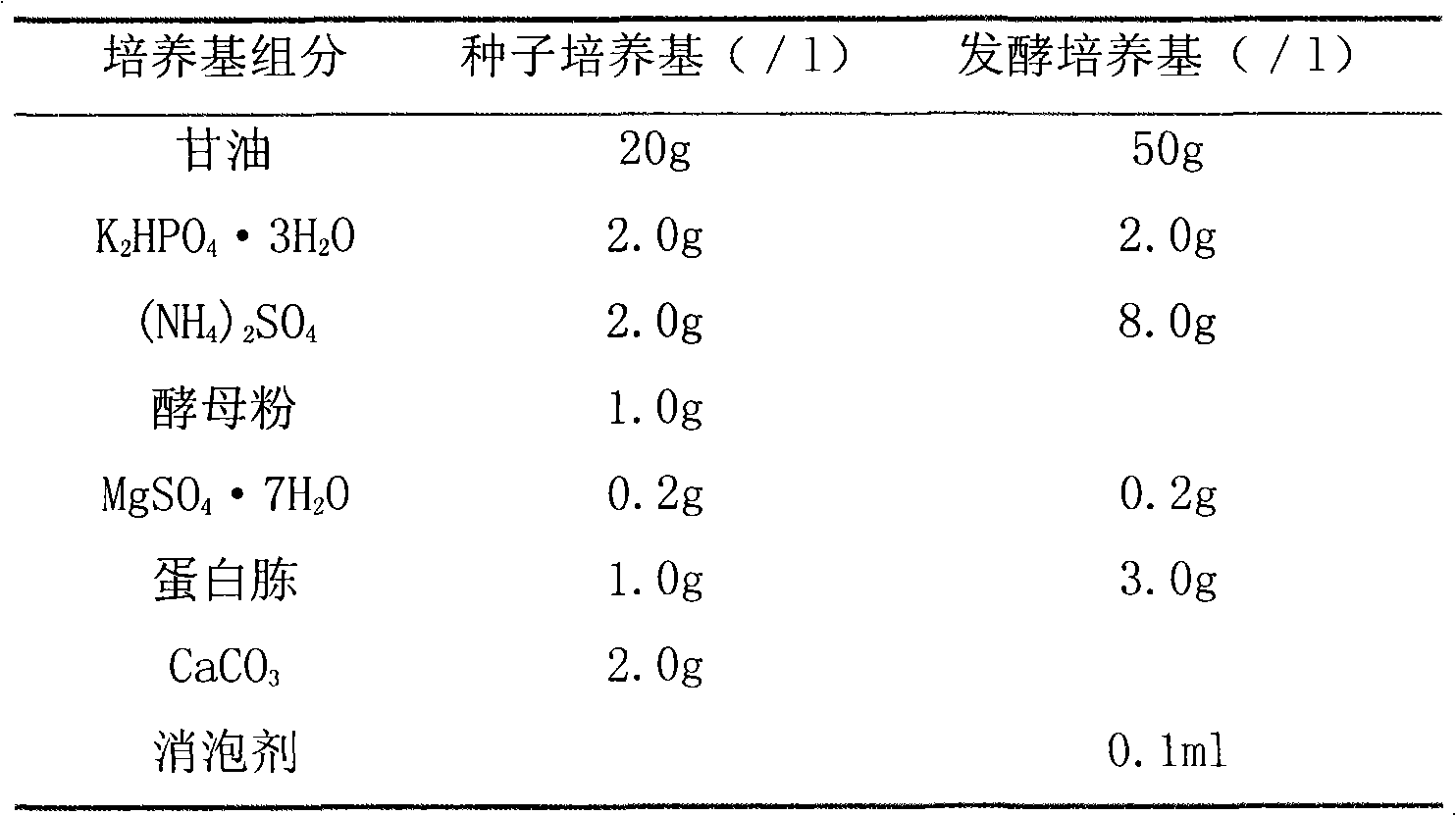

[0017] (3) Culture medium: glycerol produced by chemical method

[0018]

[0019] (4) Fermentation process:

[0020] A. Seed culture: Escherichia coli was inserted into the seed medium containing 20g / L glycerol (250ml Erlenmeyer flask, liquid volume 100ml), the culture temperature was 37°C, the shaker speed was 150rpm, and aerobic culture was carried out for 24h.

[0021] B. Fermentation culture: a 5L fermenter was used for fermentation culture, the liquid volume was 4L, the culture temperature was 37°C, and the pH value was controlled by sodium hydroxide to 6.5. The seed liquid was inserted into the initial fermentation medium containing 50g / L glycerol according to the inoculum amount of 5%. During the fermentation process, glycerin was not added, and microaerobic fermentation was adopted, 0.5vvm air was introduced, and the rotat...

example 2

[0025] (1) Fermentation method: 500mL triangular flask, shaker micro-aerobic fermentation

[0026] (2) Strains: Enterococcus faecalis

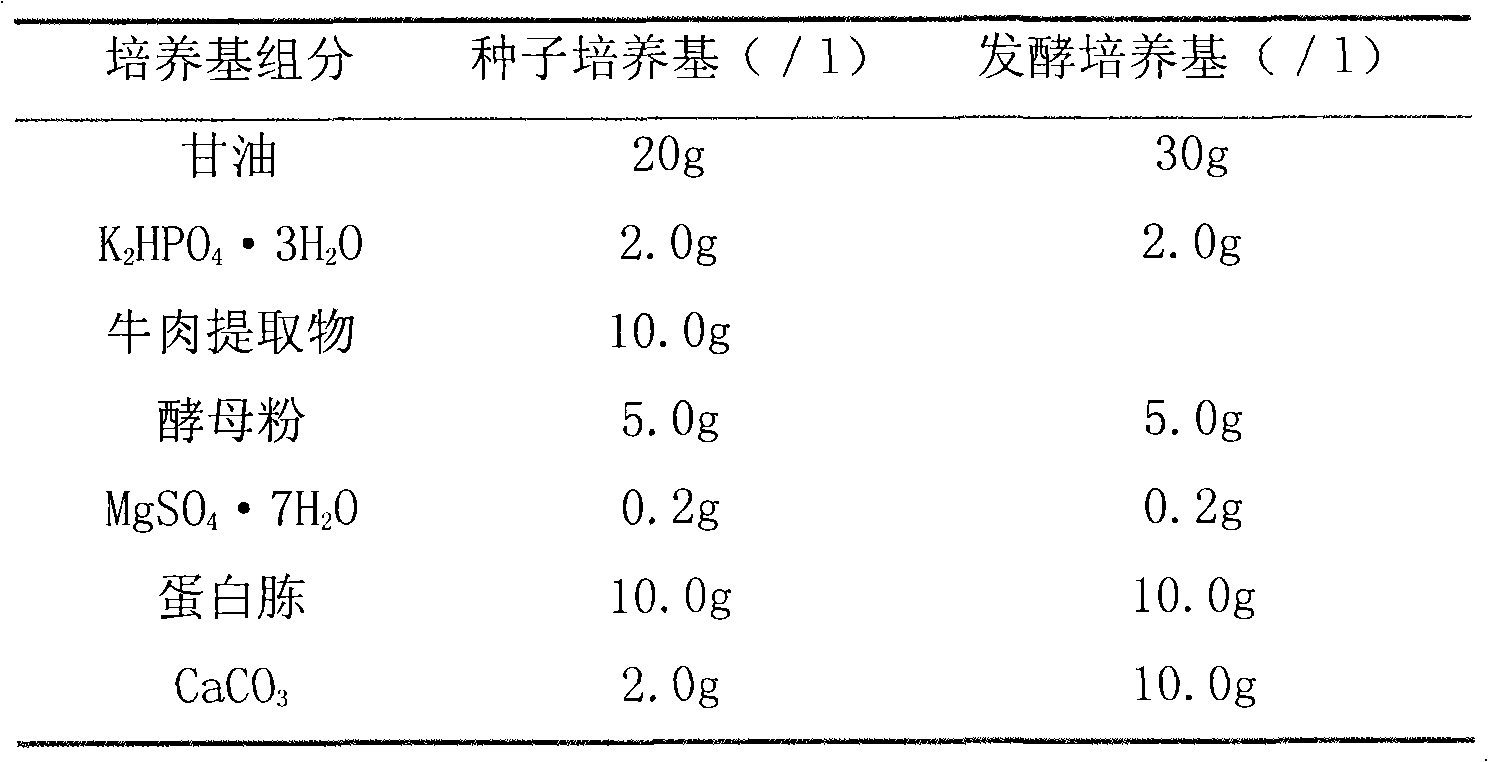

[0027] (3) Culture medium: glycerol produced by chemical method,

[0028]

[0029] (4) Fermentation process:

[0030] A. Seed culture: Inoculate Enterococcus faecalis into a seed medium containing 20g / L glycerol (250ml Erlenmeyer flask, liquid volume: 100ml), culture at 30°C, shaker speed 150rpm, aerobic culture for 24h.

[0031] B. Fermentation culture: insert the seed liquid into the initial fermentation medium containing 30g / L glycerol according to the inoculation amount of 1%, in a 500ml Erlenmeyer flask, with a liquid volume of 200ml, at a culture temperature of 37°C, at a shaker speed of 150rpm, and aerobic fermentation for 72 hours .

[0032] (5) Fermentation result:

[0033] At the end of 72hr fermentation, the concentration of lactic acid in the fermentation broth was 13.65g / l. The mass yield of lactic acid is 0.58, and the pr...

example 3

[0035] (1) Fermentation method: 5L mechanical stirring fermentation tank, air flow and batch fermentation

[0036] (2) Bacteria: Klebsiella

[0037] (3) Culture medium: Glycerol is the by-product glycerol obtained in the biodiesel production process, and a part of it is used as a fermentation substrate with an initial concentration of 30 g / l, and the other part is used for fed-batch feeding. Other ingredients are the same as Example 1

[0038] (4) Fermentation process:

[0039] A. Seed culture: insert Klebsiella into the seed medium containing 20g / L biodiesel by-product glycerin (250ml Erlenmeyer flask, liquid volume 100ml), culture temperature 37 ℃, shaker speed 150rpm, aerobic Cultivate for 24h.

[0040] B. Fermentation culture: a 5L fermenter was used for the fermentation culture, the liquid volume was 4L, the culture temperature was 41°C, and the pH value was controlled to 6.0 with sodium hydroxide. The seed liquid was inserted into the initial fermentation medium cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com