Method of preparing zinc oxide/titanium dioxide composite self-assembly thin film gas sensitive device

A technology of titanium dioxide and gas sensor, which is applied in its related fields, can solve the problems of reducing component sensitivity and life, low sensitivity, high operating temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

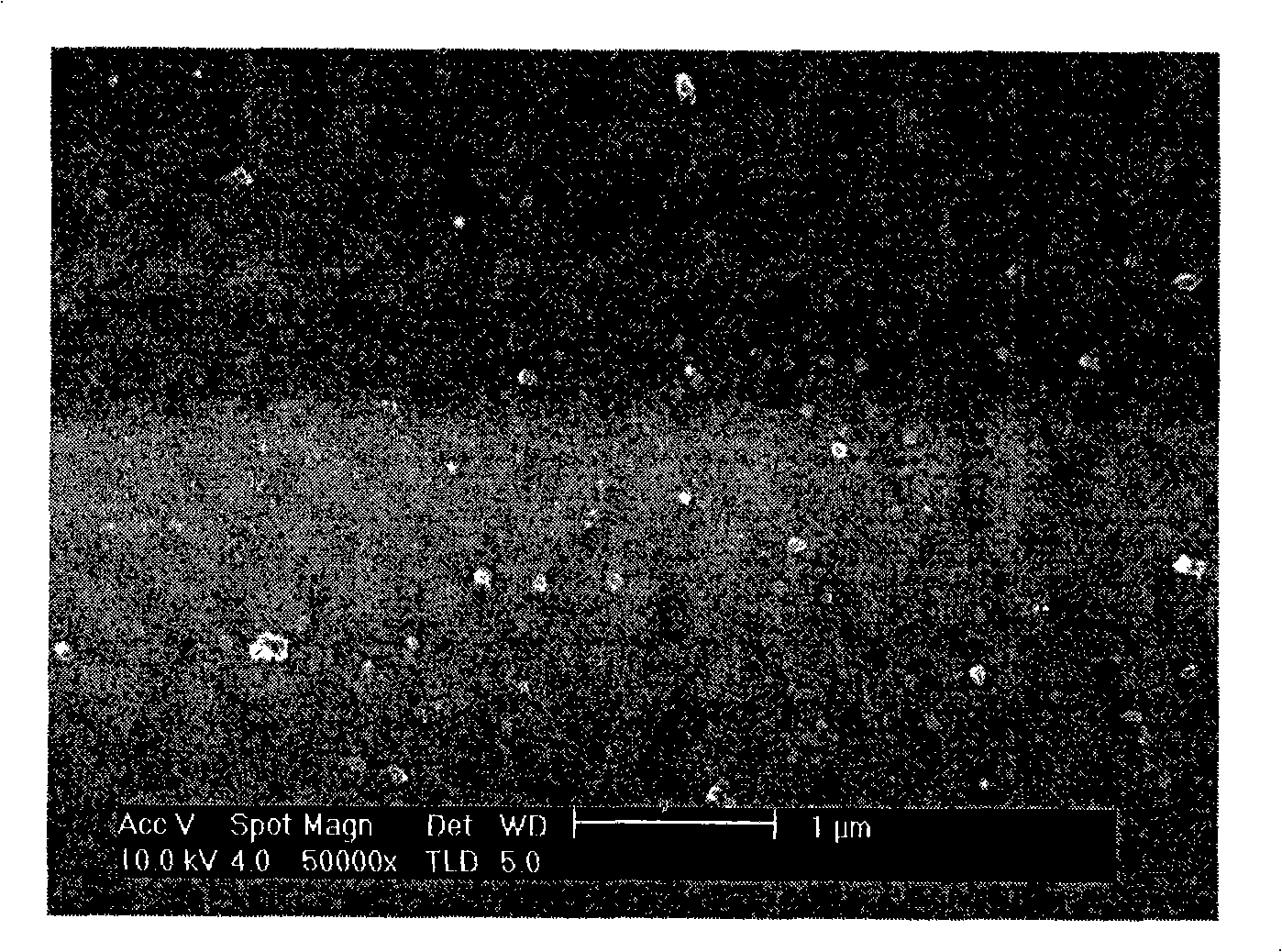

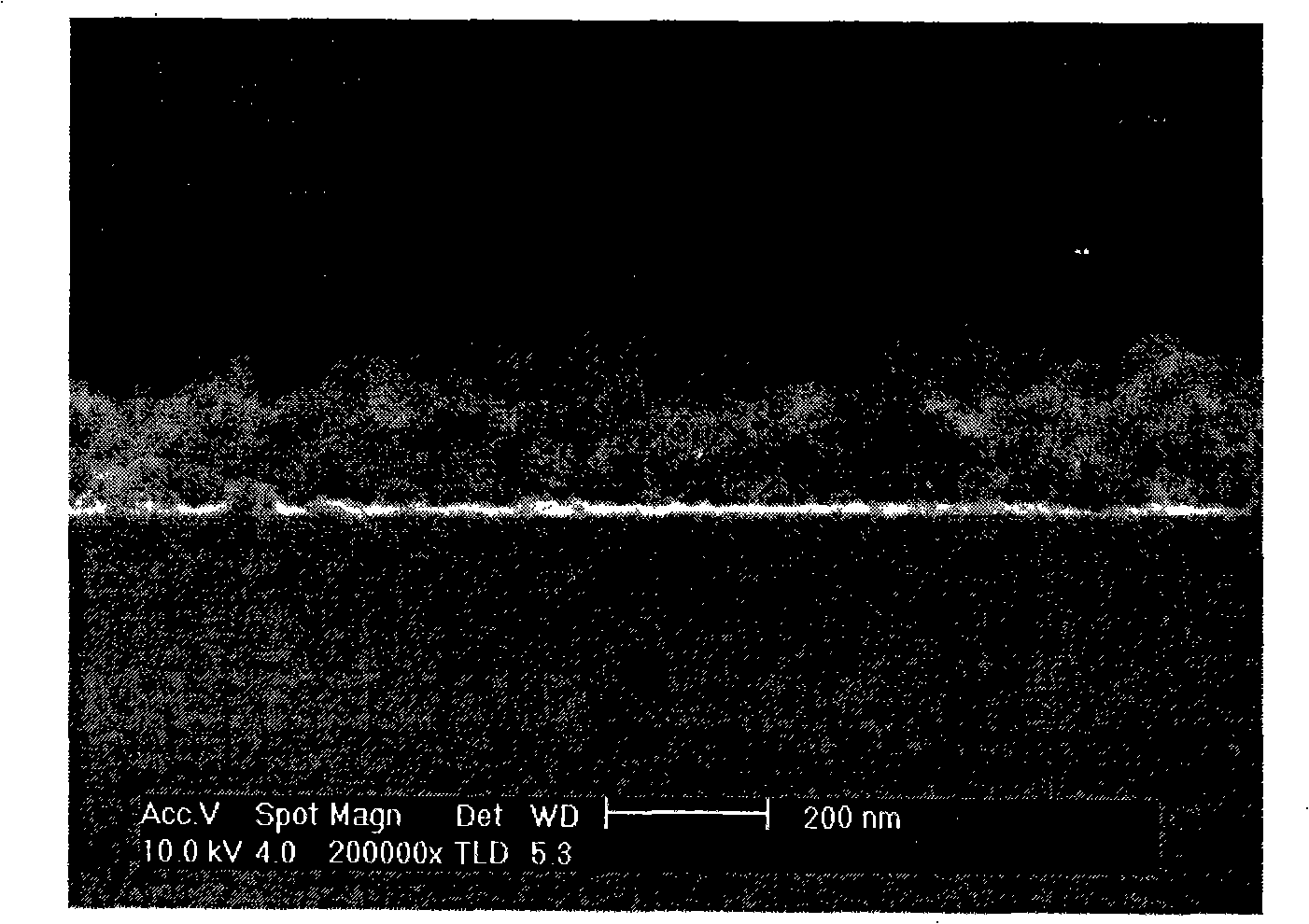

Image

Examples

Embodiment 1

[0035] A kind of ZnO / TiO of the present invention 2 A method for preparing a composite self-assembled thin film gas sensor, the preparation steps of which are as follows:

[0036] 1. Dissolve 0.5g zinc acetate in 150ml H 2 After mixing well in O, add 4ml H while stirring2 o 2 , reacted for 6h under light to obtain uniform and stable ZnO 2 Sol. Add dilute HCl to adjust its pH to 5.

[0037] 2. Dissolve 4g of tetrabutyl titanate in 20ml of ethanol, then add 3 drops of concentrated hydrochloric acid dropwise, stir and mix evenly, then slowly add 100ml of deionized water with 3 drops of concentrated hydrochloric acid into the above solution, and stir for 30 minutes , and reacted in a water bath at 40°C for 60 minutes to obtain light yellow transparent TiO 2 Sol.

[0038] 3. Prepare polyallylamine hydrochloride and polystyrene sodium sulfonate aqueous solutions with a concentration of 0.1 mg / ml as polyelectrolyte cations and polyelectrolyte anions, respectively.

[0039] 4. ...

Embodiment 2

[0045] A kind of ZnO / TiO of the present invention 2 A method for preparing a composite self-assembled thin film gas sensor, the preparation steps of which are as follows:

[0046] 1. Dissolve 1g zinc nitrate in 100ml H 2 After mixing well in O, add 2ml H while stirring 2 o 2 , reacted for 2 hours under light, then added 2ml of H 2 o 2 , after another 3h of reaction, a uniform and stable ZnO 2 Sol. Add acetic acid to adjust its pH to 4.

[0047] 2. Dissolve 10g of tetrabutyl titanate in 60ml of ethanol, then add 10 drops of concentrated hydrochloric acid dropwise, stir and mix evenly, then slowly add 300ml of deionized water with 10 drops of concentrated hydrochloric acid into the above solution, and stir for 30 minutes , and reacted in a water bath at 50°C for 120min to obtain light yellow transparent TiO 2 Sol.

[0048] 3. Prepare polydiallyldimethylammonium chloride and polyacrylic acid aqueous solutions with a concentration of 0.3 mg / ml as polyelectrolyte cations a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com