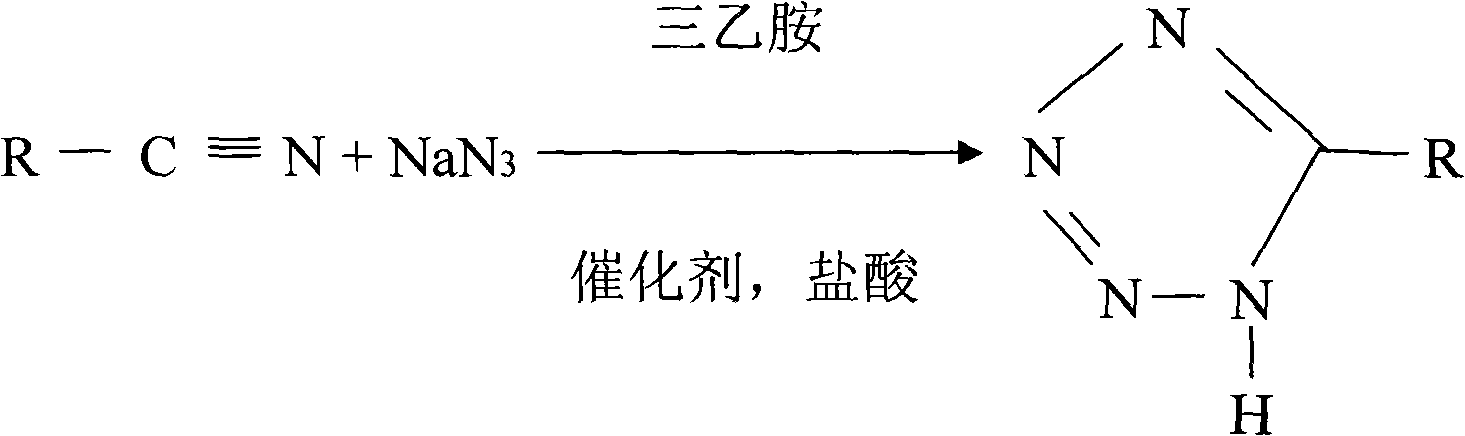

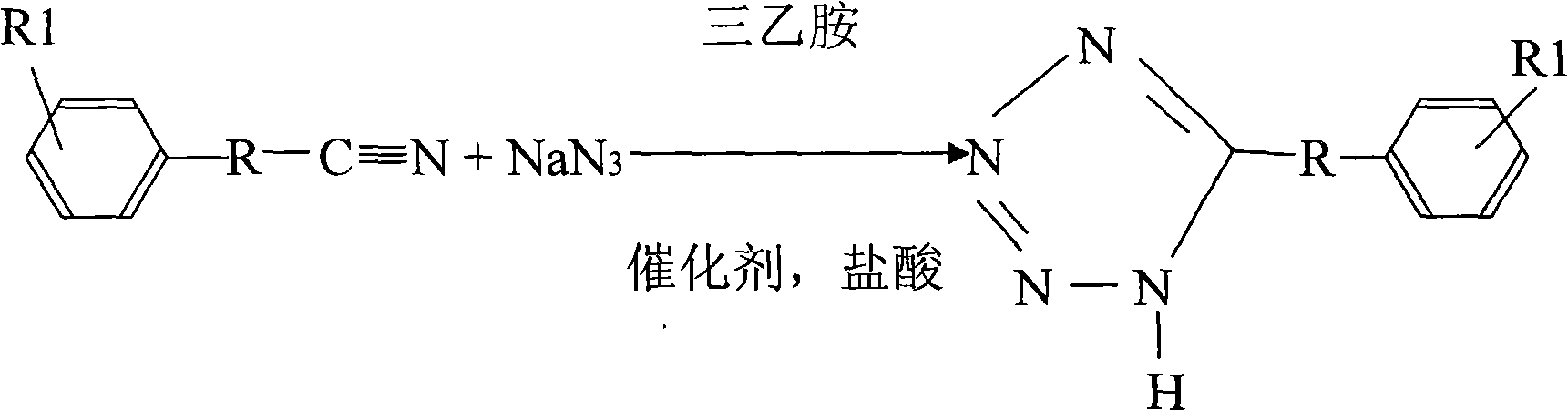

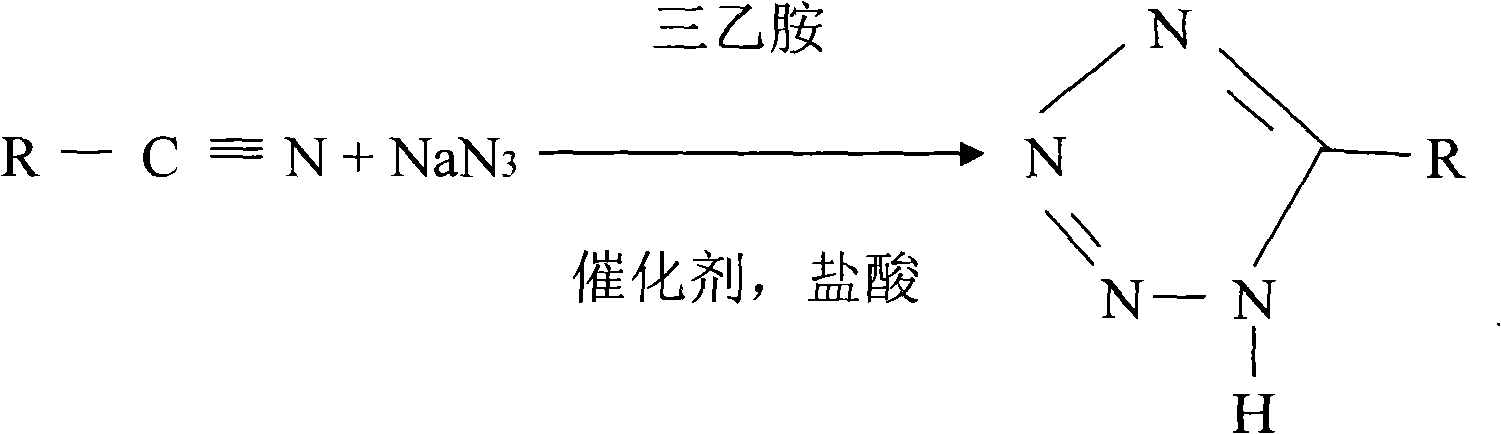

Production technique for preparing 5-alkyltetranitrozole by high pressure method

An alkane tetrazolium and production process technology, applied in the direction of organic chemistry and the like, can solve the problems of difficult pollution, low yield and high reaction temperature, and achieve the effect of less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The feed ratio is acetonitrile: sodium azide: triethylamine hydrochloric acid: triethylamine=(molar ratio) 1:1:1.5:10.

[0027] After adding the reaction materials in the autoclave with stirring according to the above ratio, close the reactor, heat up to 130°C, and react for 8 hours. After the reaction, add liquid alkali to separate layers, and the oil layer is acidified to PH1-2 with hydrochloric acid. The water was distilled off under reduced pressure to obtain a solid product, and the distilled water was used to prepare liquid caustic soda with solid sodium hydroxide. The product solid was heated and extracted with ethyl acetate, and refined to obtain the product, with a content of 99.2% and a molar yield of 95.4%.

Embodiment 2

[0029] The feeding ratio is propionitrile: sodium azide: triethylamine hydrochloric acid: triethylamine=(molar ratio) 1:1:1.5:10.

[0030] After adding the reaction materials in the autoclave with stirring according to the above ratio, close the reactor, heat up to 130°C, and react for 8 hours. After the reaction, add liquid alkali to separate layers, and the oil layer is acidified to PH1-2 with hydrochloric acid. The water was distilled off under reduced pressure to obtain a solid product, and the distilled water was used to prepare liquid caustic soda with solid sodium hydroxide. The product solid was heated and extracted with ethyl acetate, and refined to obtain the product with a content of 99.4% and a molar yield of 93.2%.

Embodiment 3

[0032] The feed ratio is benzonitrile: sodium azide: triethylamine hydrochloric acid: triethylamine=(molar ratio) 1:1:1.5:10.

[0033] After adding the reaction materials in the autoclave with stirring according to the above ratio, close the reactor, heat up to 130°C, and react for 8 hours. After the reaction, add liquid alkali to separate layers, and the oil layer is acidified to PH1-2 with hydrochloric acid. The water was distilled off under reduced pressure to obtain a solid product, and the distilled water was used to prepare liquid caustic soda with solid sodium hydroxide. The product solid was heated and extracted with ethyl acetate, and refined to obtain the product with a content of 99.5% and a molar yield of 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com