Method for preparing polymer colloid photon crystal film by using spraying method

A colloidal photonic crystal, polymer latex technology, applied in optics, optical components, instruments, etc., to achieve the effect of simple and rapid preparation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

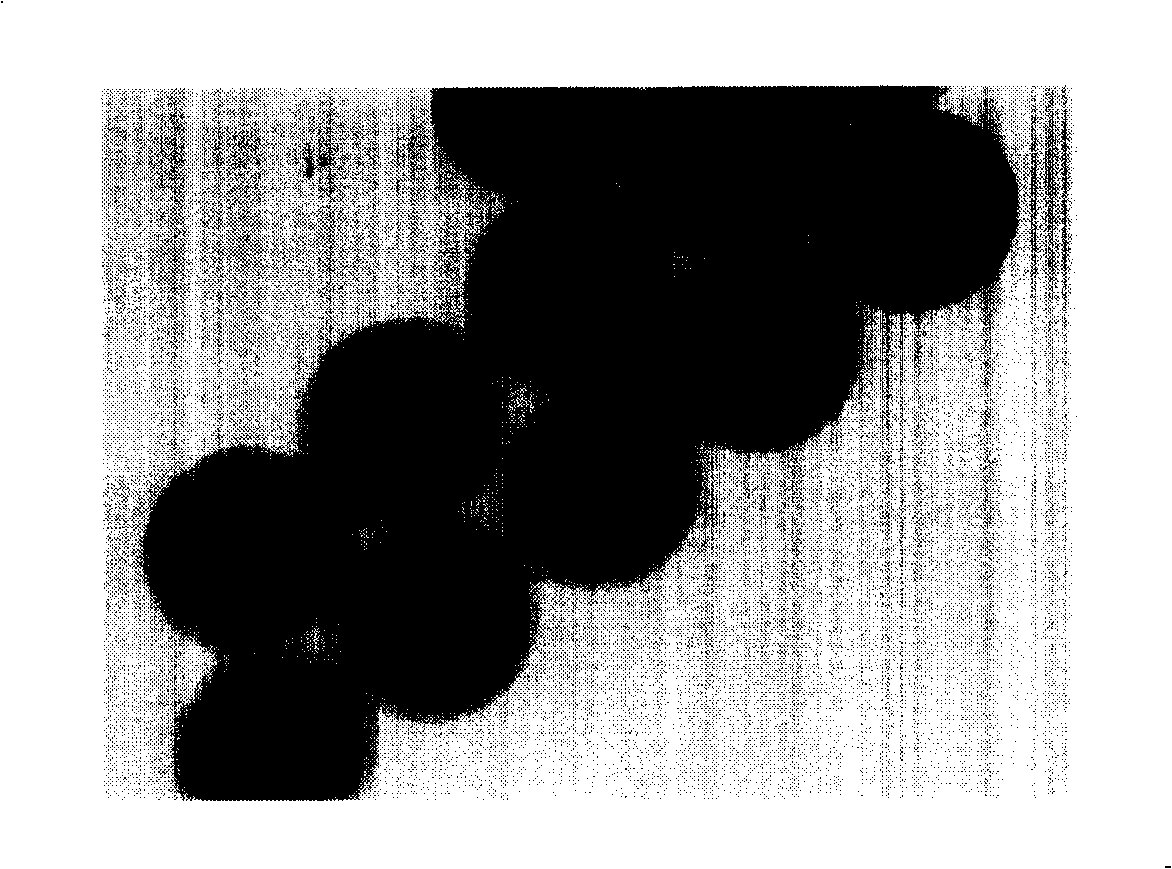

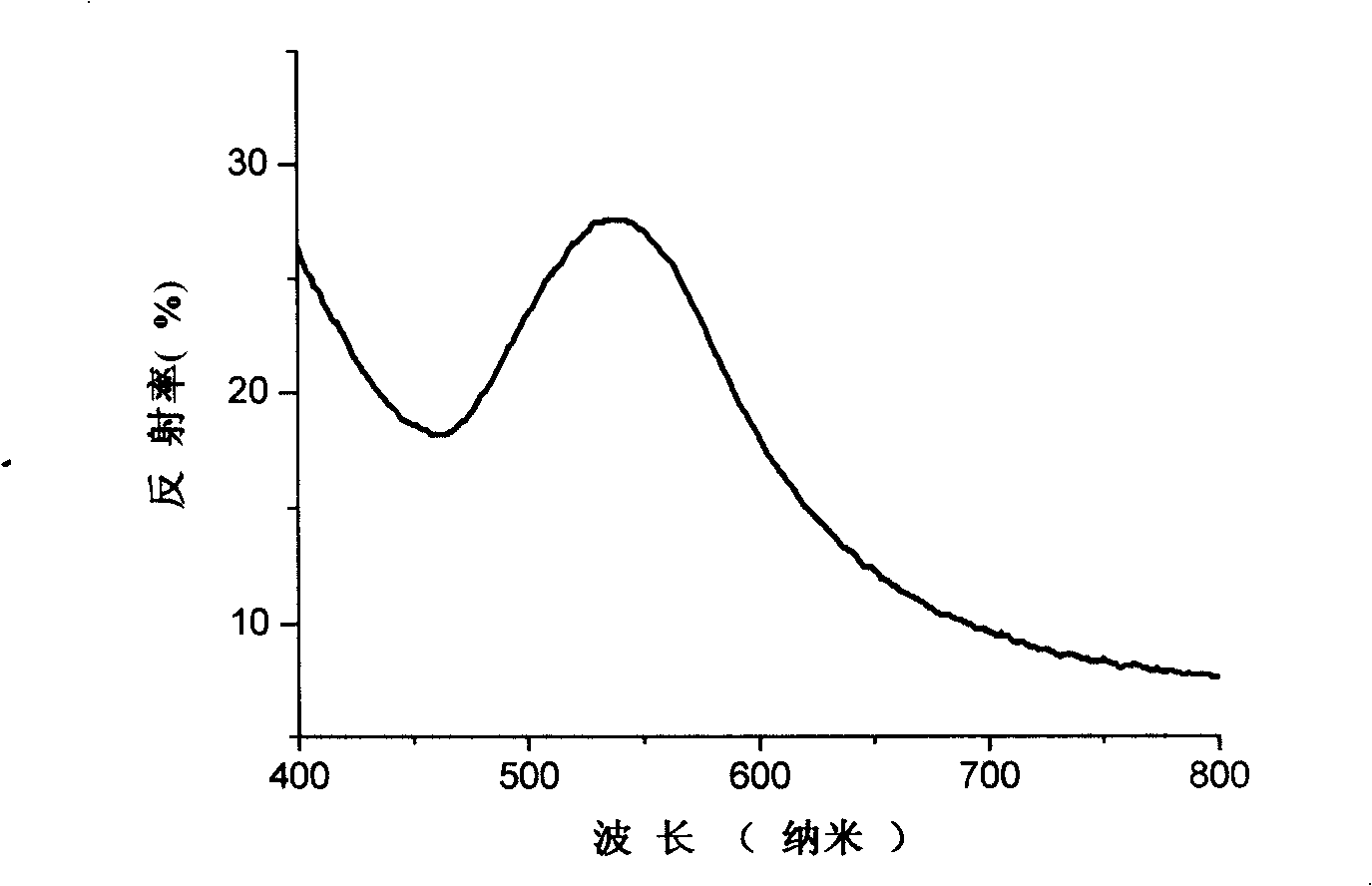

[0045] The poly(styrene-methyl methacrylate-acrylic acid) monodisperse latex particles (particle size) with a hard core-soft shell structure prepared by the previous patent application method at a concentration of 10wt% at room temperature (25°C) It is 210nm, the shell thickness is 35nm, it has obvious core-shell structure, see figure 1 ) Is added to a container with an air spray gun, and the monodisperse colloidal particle water dispersion is sprayed on the glass substrate through the air spray gun. After the water in the dispersion is volatilized under the action of the gun body gas, it will Obtained monodisperse polymer latex particles (poly(styrene-methyl methacrylate-acrylic acid)) on the surface of the substrate to form a colloidal three-dimensional photonic crystal film that is periodically arranged and orderly stacked in a face-centered cube; After drying, the film is peeled from the substrate to obtain a polymer colloidal photonic crystal film with a photonic band gap in...

Embodiment 2

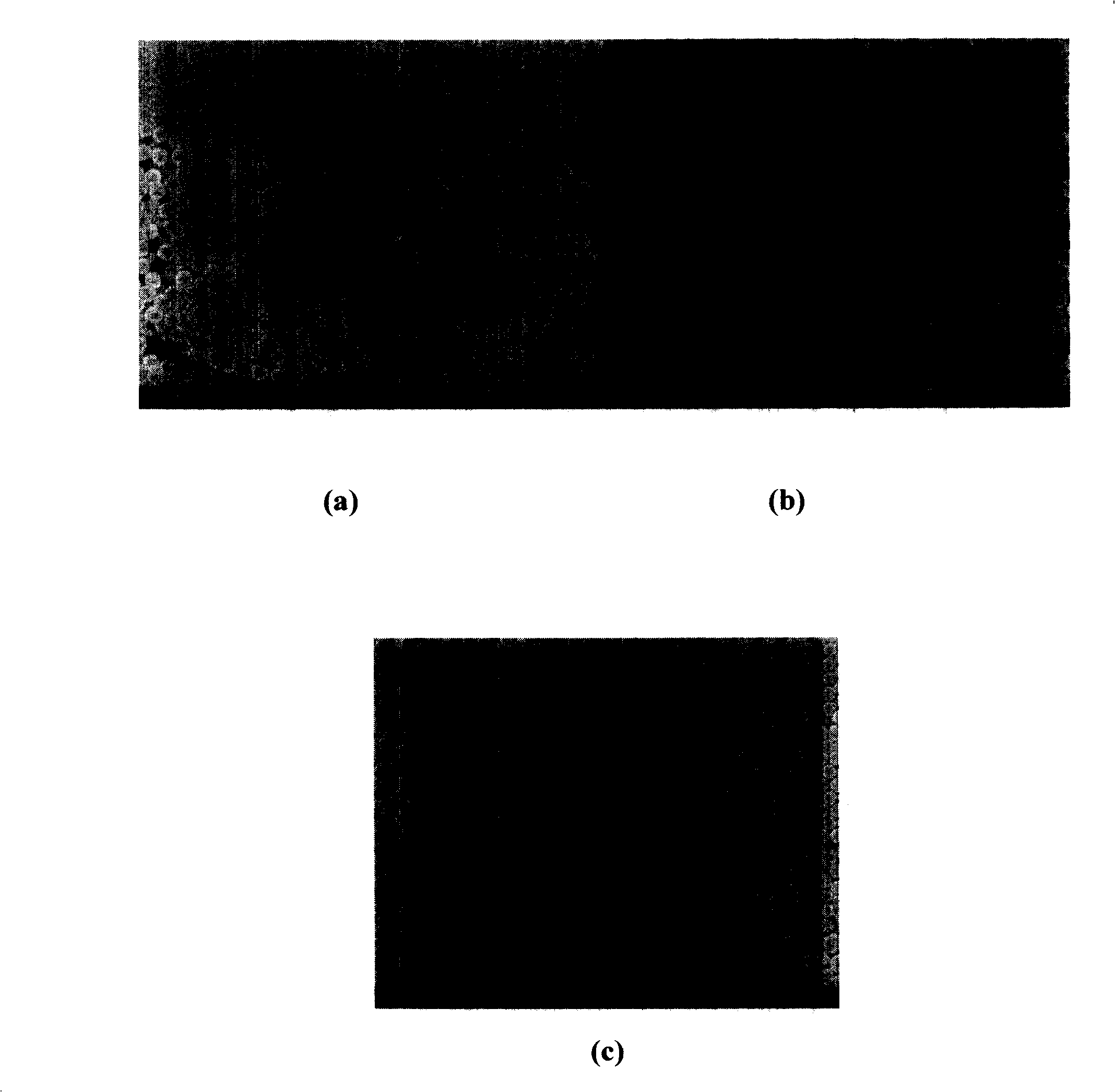

[0047] The monodisperse poly(styrene-methyl methacrylate-acrylic acid) with a hard core-soft shell structure prepared by the method of the previous patent application at a concentration of 15wt% at room temperature (particle size of 244,191 nm, respectively) ) Is added to a container with an air spray gun, and the water dispersion of monodisperse polymer latex particles is sprayed on the glass substrate through the air spray gun. After the dispersion is volatilized under the action of the gun body gas, The monodisperse polymer latex particles are formed on the surface of the substrate to form a colloidal three-dimensional photonic crystal film that is periodically arranged and orderly stacked in a face-centered cube; after the coating is dried, the film is peeled from the substrate to obtain The polymer colloidal photonic crystal film with the photonic band gap in the visible region, image 3 (b) and image 3 (c) Scanning electron micrographs of the coating film obtained by air sp...

Embodiment 3

[0049] The monodisperse poly(styrene-methyl methacrylate-acrylic acid) with a hard core-soft shell structure prepared by the method of the previous patent application at a concentration of 19% by weight at room temperature (particle size 280,270, respectively) 244, 216, 204, 191, 173 nm) water dispersion is added to a container with an air spray gun, and the water dispersion of monodisperse polymer latex particles is sprayed on the paper or stainless steel plate substrate through the air spray gun. After the dispersion is volatilized under the action of the gun body gas, monodisperse polymer latex particles are obtained to form a colloidal three-dimensional photonic crystal film that is periodically arranged and orderly arranged on the surface of the substrate and stacked in face-centered cubes; After drying, the film is peeled from the substrate to obtain a polymer colloidal photonic crystal film with a photonic band gap in the visible region. Figure 4 (a), (b) and Figure 4 (c) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com