Luminous rare earth metal complexes and adjustable luminous nano film prepared by the same

A technology of rare earth metals and complexes, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of luminous intensity, tunability, thermal stability defects, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of NTB ligand:

[0029] (1) Add 16.2g (0.15mol) o-phenylenediamine and 9.6g (0.05mol) amine triacetic acid in a 250ml round bottom flask, add 60ml ethylene glycol and stir well, and heat the oil bath to 150°C and reflux for 10 hours During the reaction, a water separator can be installed to lead the generated water out of the reaction system; after the reaction is completed, it is poured into 200ml of water while stirring, filtered, and recrystallized with ethanol (decolorized with activated carbon if necessary) to obtain the product NTB, with a yield of 85 %.

[0030] (2) In a 150ml three-necked flask, add 1.02g (0.0025mol) NTB and 50ml of tetrahydrofuran treated with sodium metal, and add 0.3g (0.0077mol) in batches under the protection of nitrogen flow. For the water that has been removed, a slight excess of potassium metal is required) Metal potassium, until no hydrogen is produced, and then reflux for 1-2 hours, the system becomes white and turbid; at this ...

Embodiment 2

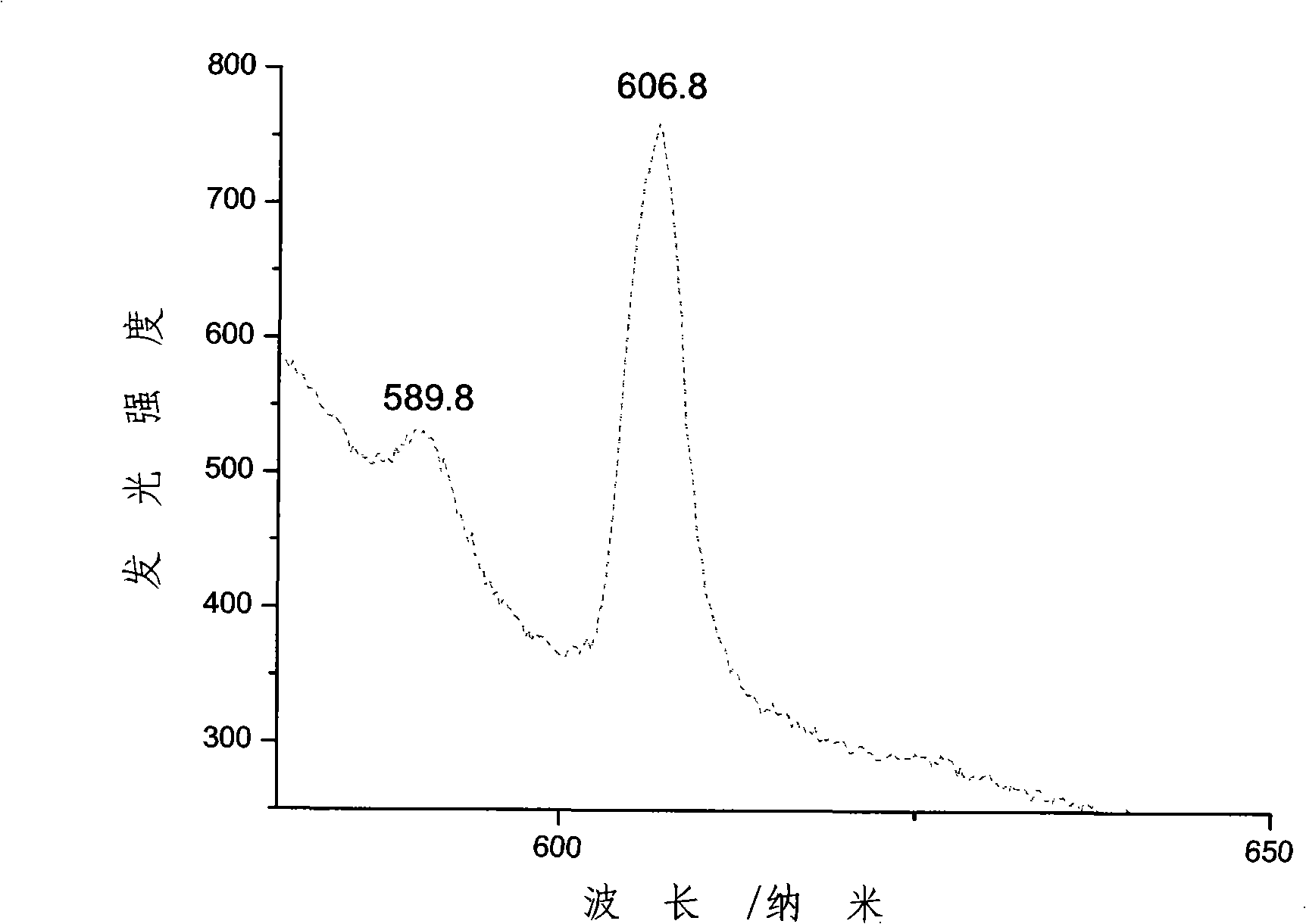

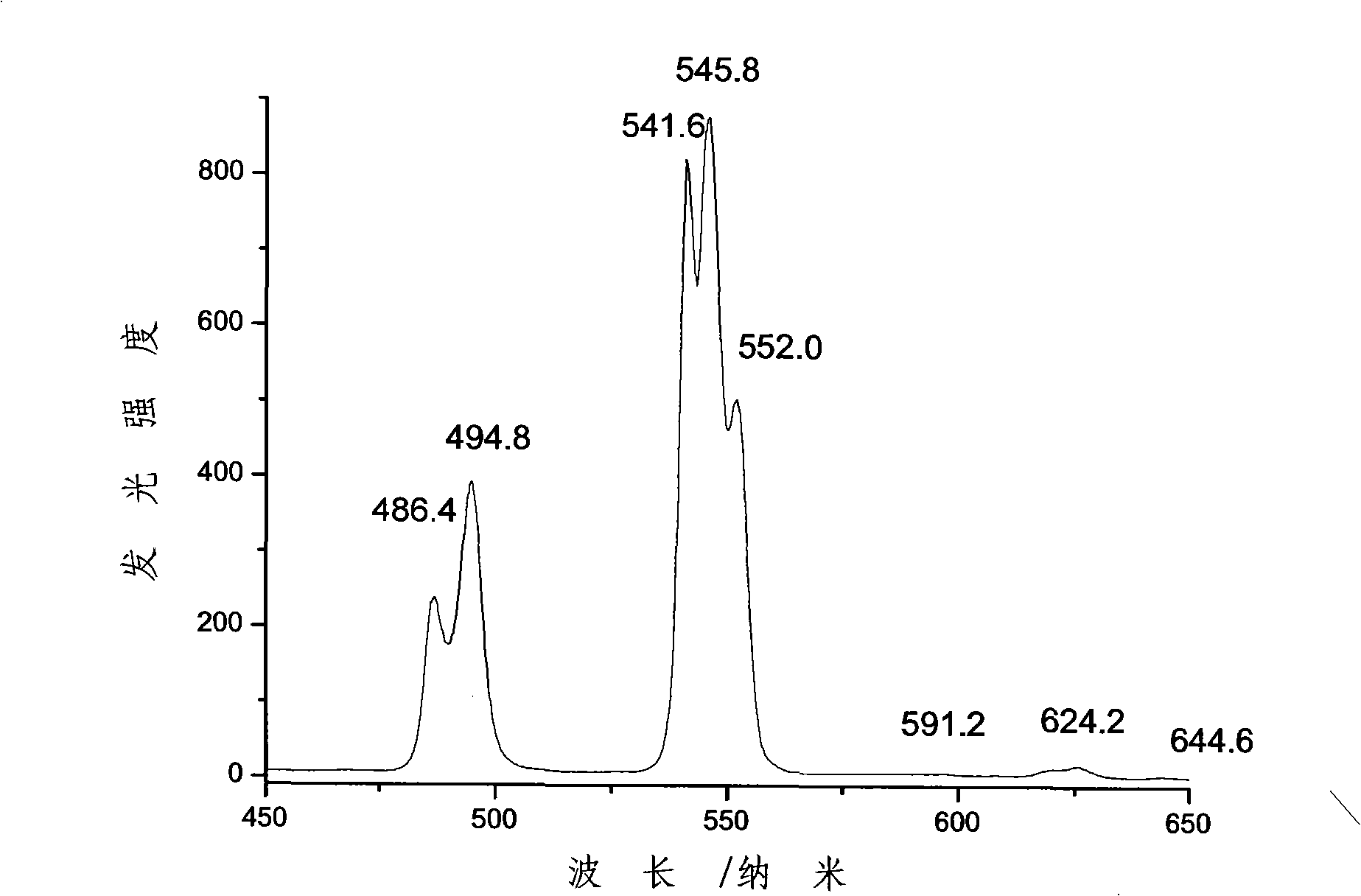

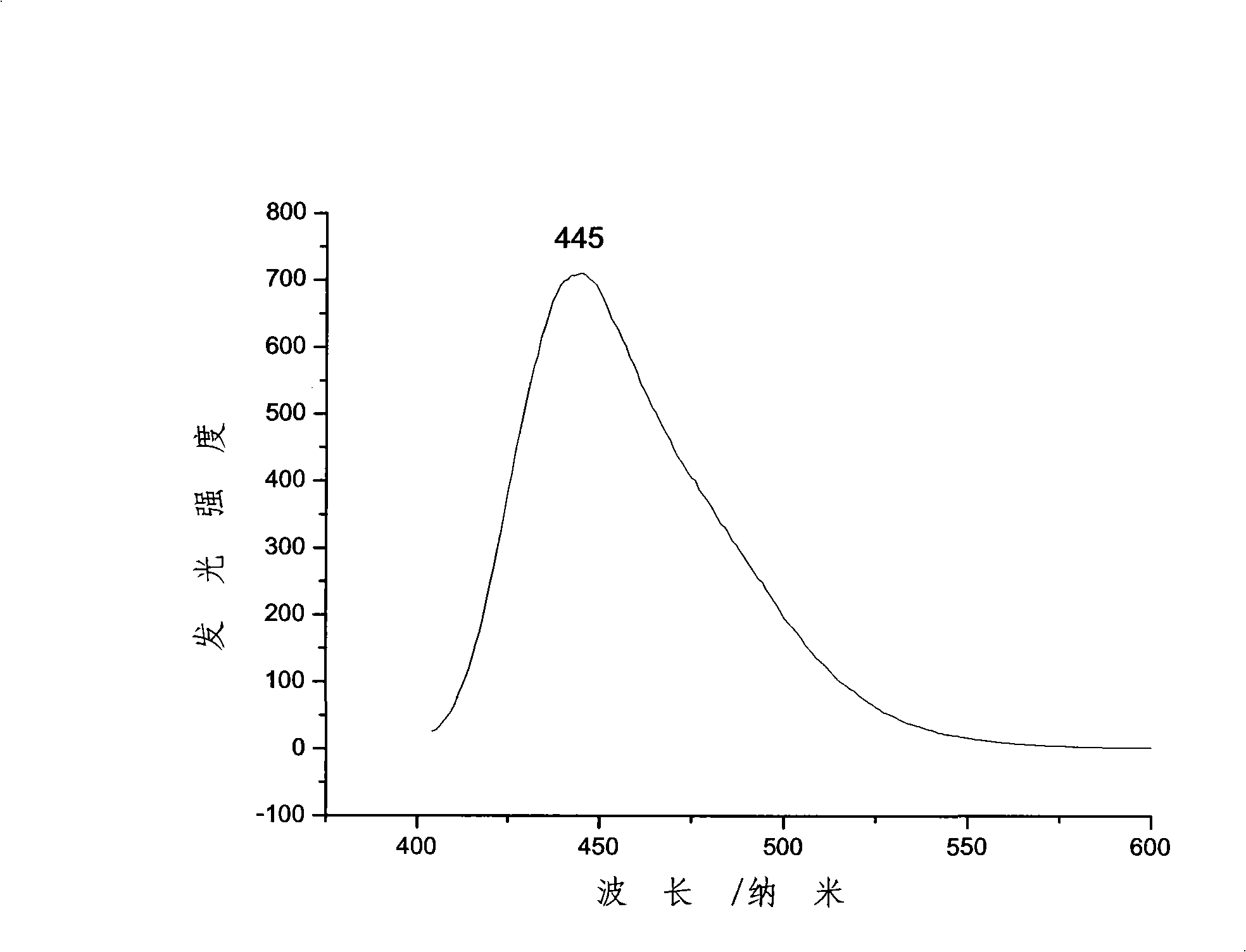

[0032] Preparation of rare earth metal complexes

[0033] Dissolve 0.05mmol NTB ligand in 5ml ethanol, then slowly add 5ml 0.025mmol rare earth salt (Ln(ClO 4 ) 3 ) (Ln=Eu, Tb, Ce) ethanol solution, stand overnight to obtain a white powder solid, filtered, washed with ethanol and ether, and placed in a desiccator to obtain the product with a yield of 50%.

Embodiment 3

[0035] Preparation of precursor sol

[0036] (1) Weigh the NTB or substituted NTB complexes of Eu, Tb, Ce with a molar ratio of 1:1:1, and dissolve them in a mixed solution of acetonitrile:ethanol=1:1 (the total molar concentration of rare earth metals is 10 -3 mol / l), then add a certain amount of tetrabutyl titanate (total moles of rare earth metal: moles of tetrabutyl titanate = 1:6), stir evenly, so that the solvent volatilizes to the total molar concentration of rare earth ions approximately It is 0.125mol / l.

[0037] (2) Use a particle size ≤0.2μm syringe filter to filter out the fine insoluble particles in the solution to prevent it from polluting the membrane. The filtered solution was slowly stirred with a magnetic stirrer at room temperature for 24 hours to fully hydrolyze, and then sealed and aged for more than three days to obtain a transparent and uniform precursor sol suitable for homogenization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com