Device and technique for indirectly electric oxidation synthesis of organic substance electrolytic regeneration medium

An electrolysis device and electrolysis regeneration technology, applied in the direction of electrolysis organic production, electrolysis components, electrolysis process, etc., can solve the problems of low reaction time and space efficiency, short motor service life, and easily polluted electrodes, etc., and achieve replacement of diaphragms and filler particles. The effect of convenience, large working current and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

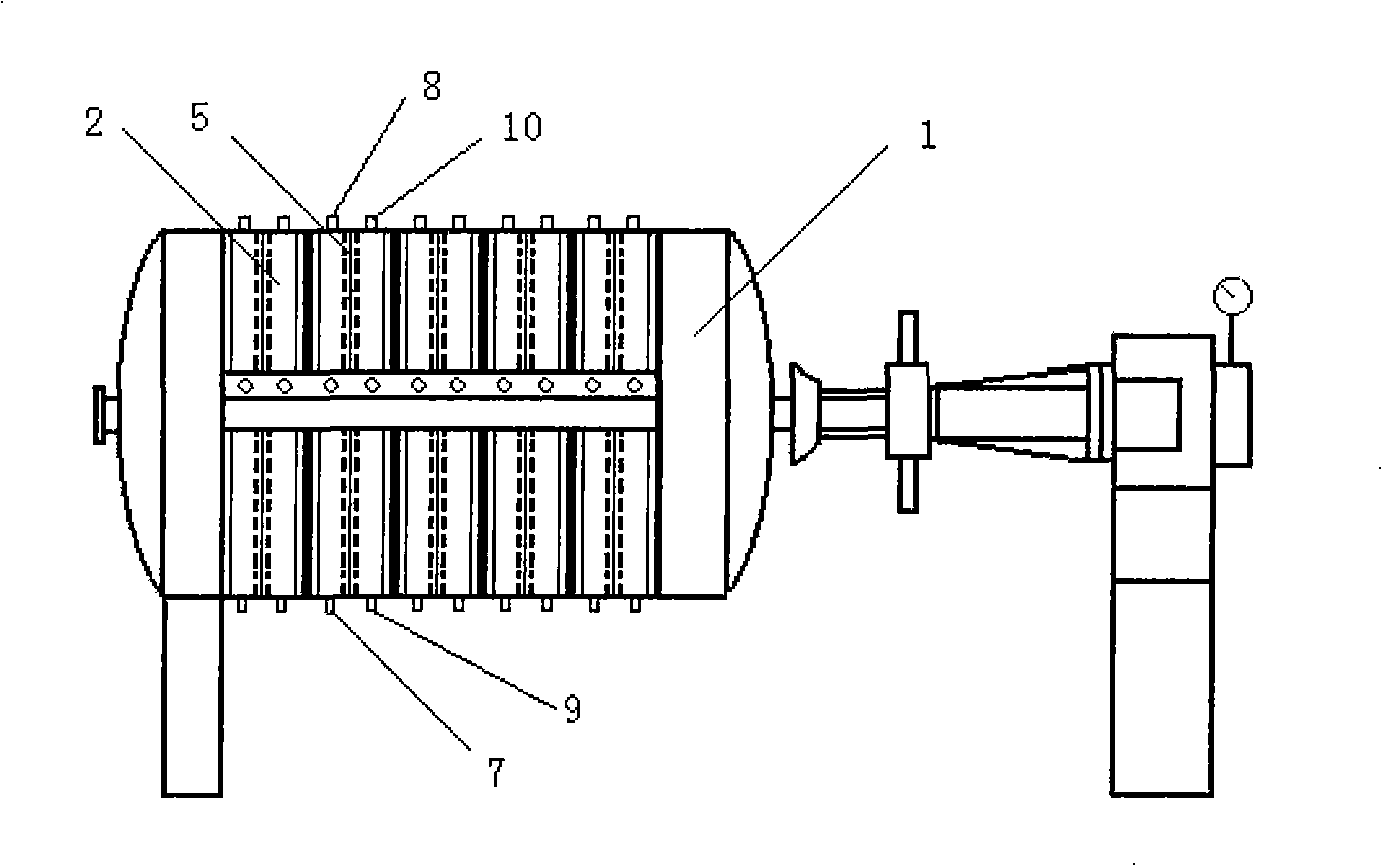

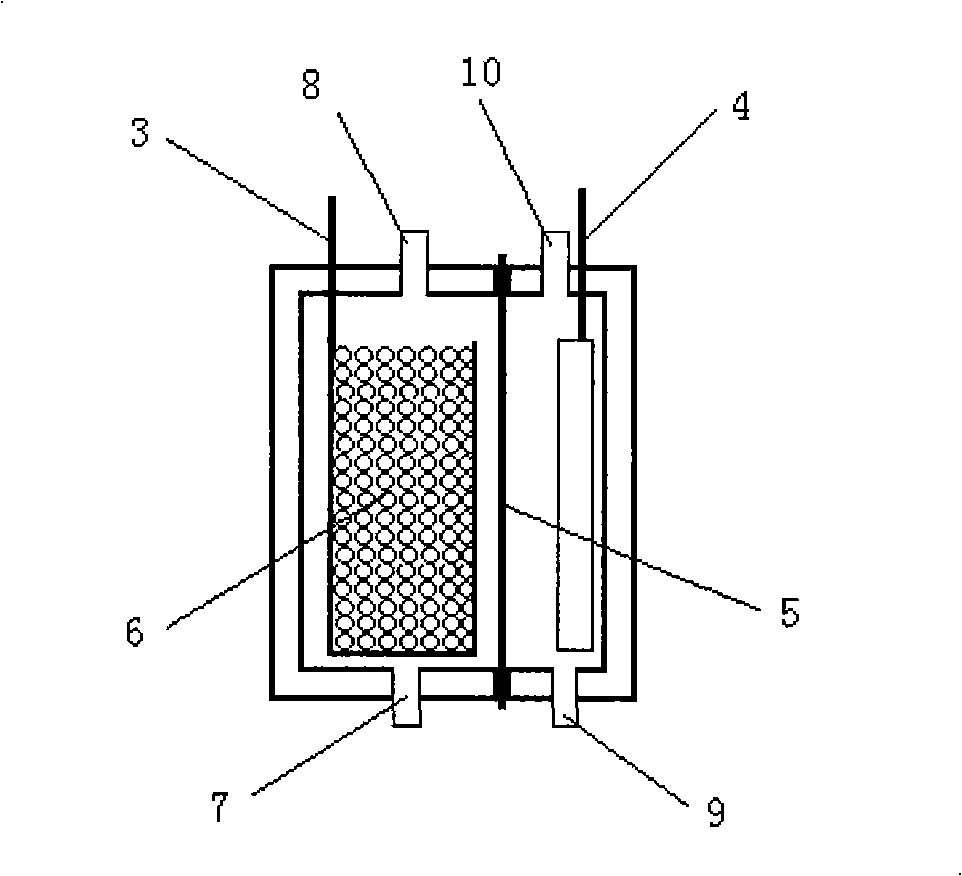

[0024] The electrolysis device is composed of 15 unit electrolyzers 2 connected in series and pressurized by a plate and frame filter press 1. The unit electrolyzer 2 includes an anode chamber and a cathode chamber separated by a cation diaphragm 5, and the anode chamber is provided with an anode chamber. The anode chamber electrolyte inlet 7 connected with the electrolyte storage tank and the anode chamber electrolyte outlet 8, the cathode chamber is provided with the cathode chamber electrolyte inlet 9 and the cathode chamber electrolyte outlet 10 connected with the catholyte storage tank, the anode The frame body of the anode particle packed bed electrode 3 in the chamber is a mesh titanium basket coated with iridium titanium noble metal oxide coating, the filler particles are graphite particles, and the cathode 4 in the cathode chamber is a copper electrode.

[0025] The anode compartment electrolyte inlet 7 of the unit electrolytic cell is communicated with the anolyte hea...

Embodiment 2-10

[0033] Different particle packed bed anodes were used, and other experimental devices, specific processes and parameters were the same as in Example 1, and the results are shown in Table 1.

[0034] Example

[0035] 5

Embodiment 11

[0037] The electrolysis device is composed of 10 unit electrolyzers connected in series, the cathode adopts a lead-antimony alloy electrode, and the others are the same as in Embodiment 1.

[0038] Specific process: a company uses Mn 2 (SO 4 ) 3 / MnSO 4 As the medium, p-fluorotoluene is synthesized by indirect electro-oxidation to p-fluorobenzaldehyde. In the indirect electro-oxidative synthesis of organic matter, the raw material p-fluorotoluene is replaced by the high-valence medium Mn 2 (SO 4 ) 3 Oxidized to the product p-fluorobenzaldehyde, after the product is separated, the water phase is the reduced low-valence medium MnSO 4 Solution, with the electrolysis device of the present invention, electrolytic regeneration MnSO 4 for Mn 2 (SO 4 ) 3 . Other processing steps are with embodiment 1.

[0039] The electrolysis parameters are controlled as follows: the anolyte solution is 6mol / LH 2 SO 4 solution, Mn 2+ The concentration is 0.5mol / L; the catholyte solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com