Ceramic hollow board cementation and formation method and uses thereof

A technology of forming and forming ceramic solar panels, which is used in the manufacture of ceramic products and ceramic products for solar energy, radiators, and far-infrared fields. It can solve problems such as complex structures, high prices, and easy generation of pores and bubbles, and achieve High average efficiency, low cost, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

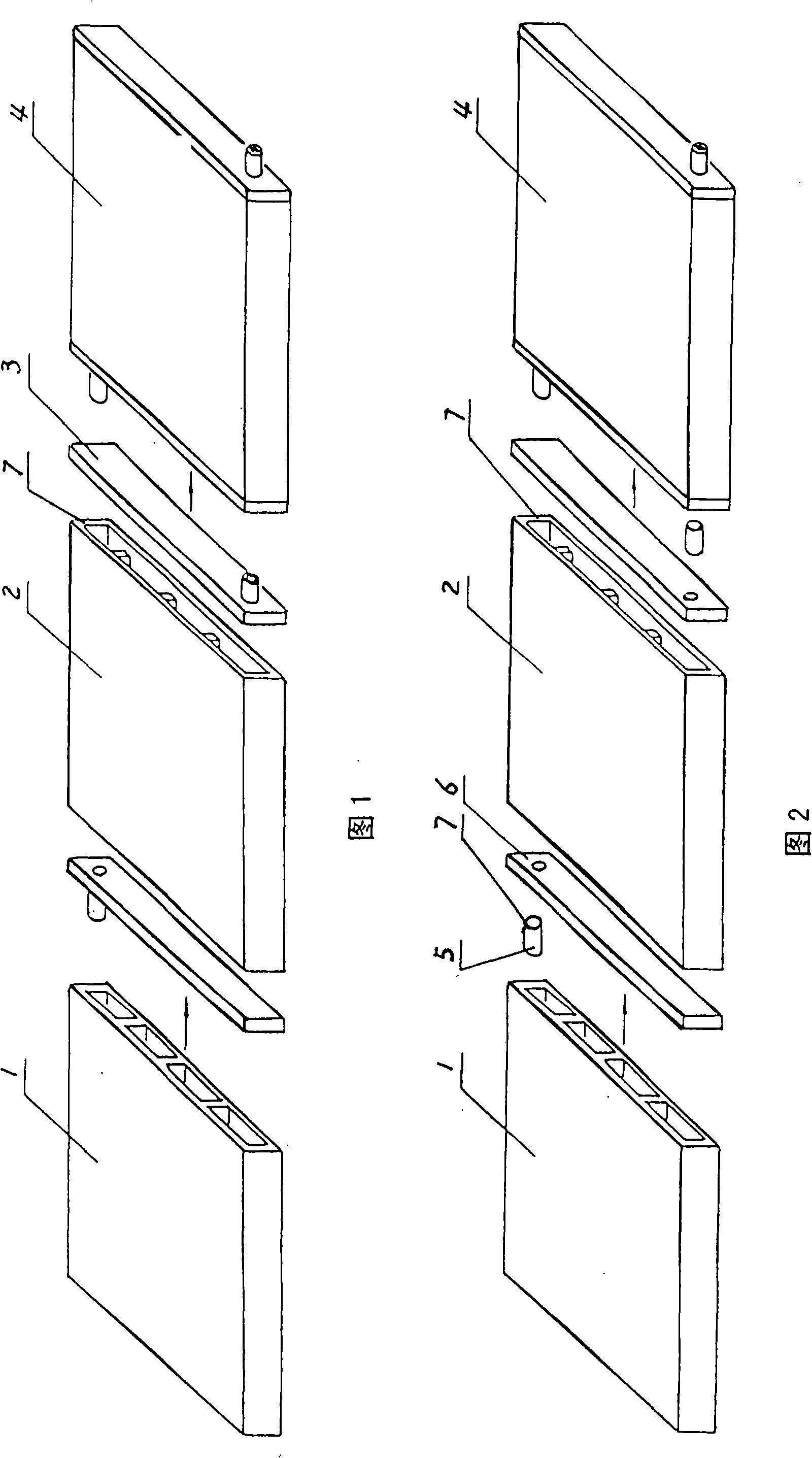

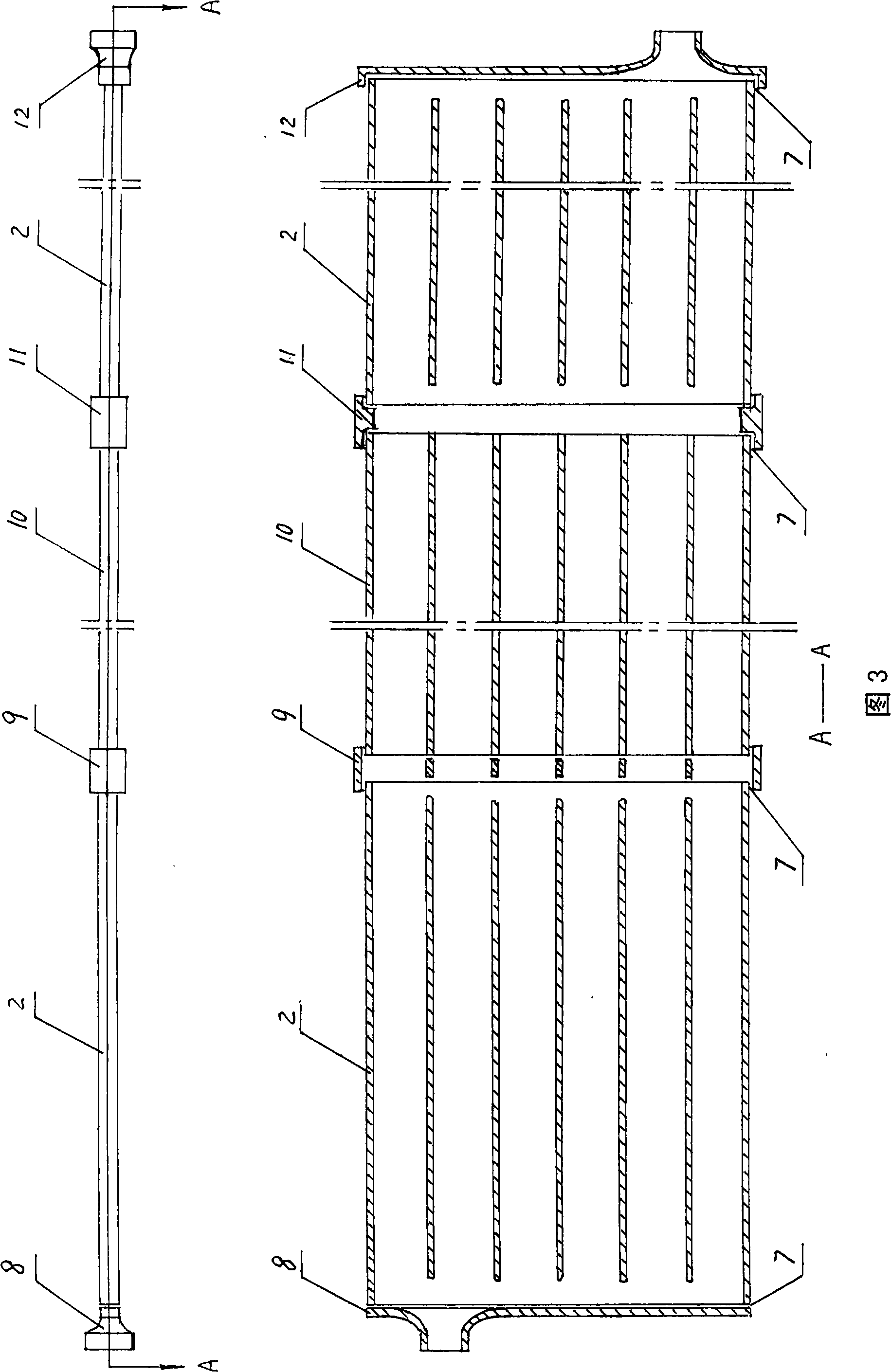

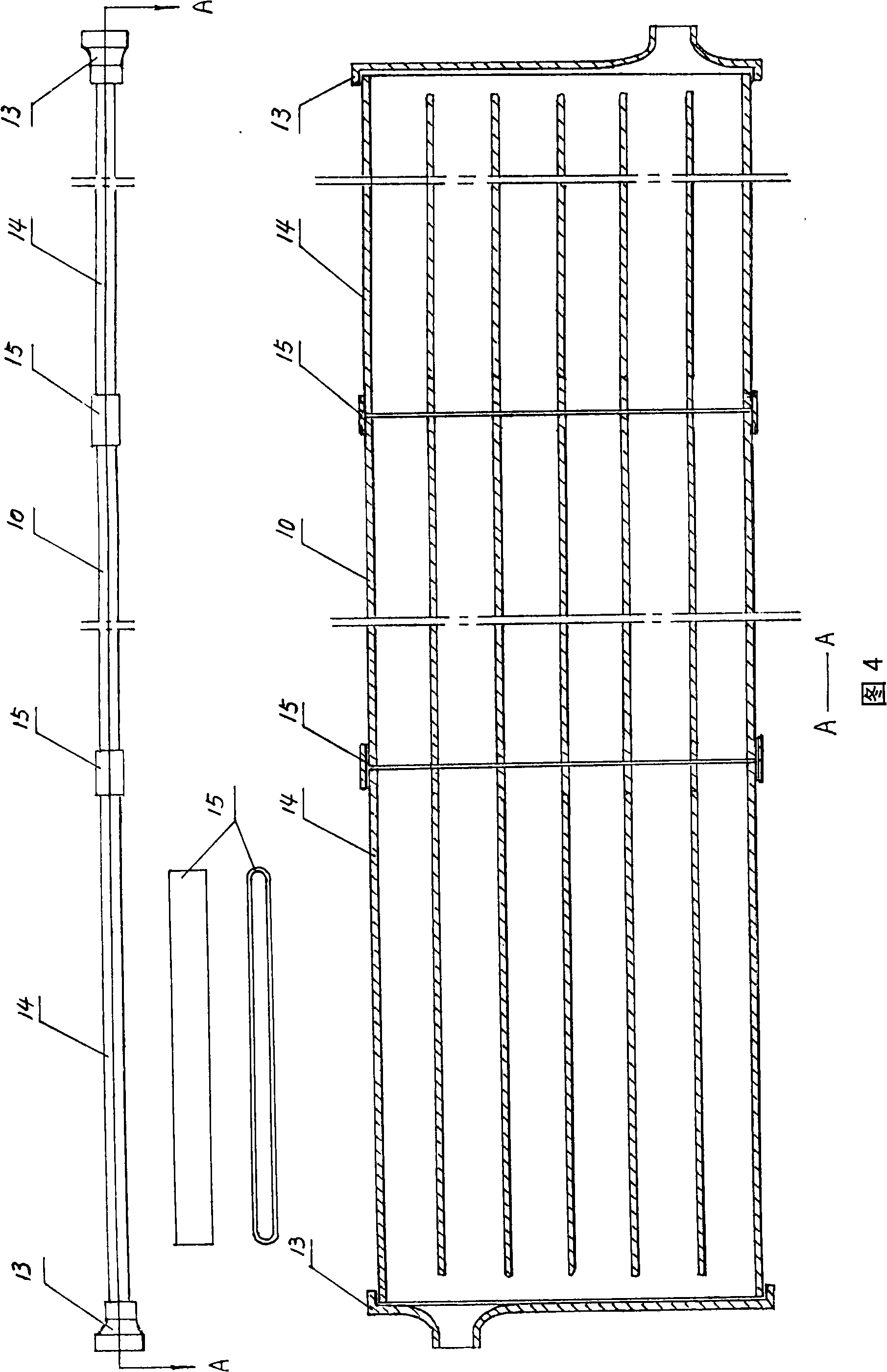

[0037] 1. The ceramic through-hole plate is bonded with epoxy resin to the ceramic end plate of the inlet and outlet nozzle, and heated and cured to form a cemented ceramic hollow plate, which is used as a ceramic solar panel and a ceramic far-infrared heat dissipation plate.

[0038] 2. The ceramic hollow plate as described in embodiment 1, wherein the adhesive is a phenolic resin film, which is used as a ceramic solar panel or a ceramic far-infrared heat dissipation plate.

[0039] 3. The ceramic hollow plate as described in embodiment 1, wherein the adhesive is a silicone rubber adhesive, which is used as a ceramic solar panel or a ceramic far-infrared heat dissipation plate.

[0040] 4. The ceramic solar panel as described in embodiment 1, wherein the adhesive adopts polyimide adhesive, which is used as a ceramic solar panel and a ceramic far-infrared cooling plate.

[0041] 5. Glue the two ends of the ceramic through-hole plate with organic adhesive such as silicone rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com