Method for removing heavy metal in urban sludge by employing electric repairing technique

A technology for municipal sludge and electric remediation, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve technical complexity, lack of enhancement technology, and insignificant removal of heavy metals from sludge, etc. problem, to achieve the effect of low treatment cost, enhanced repair effect, good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

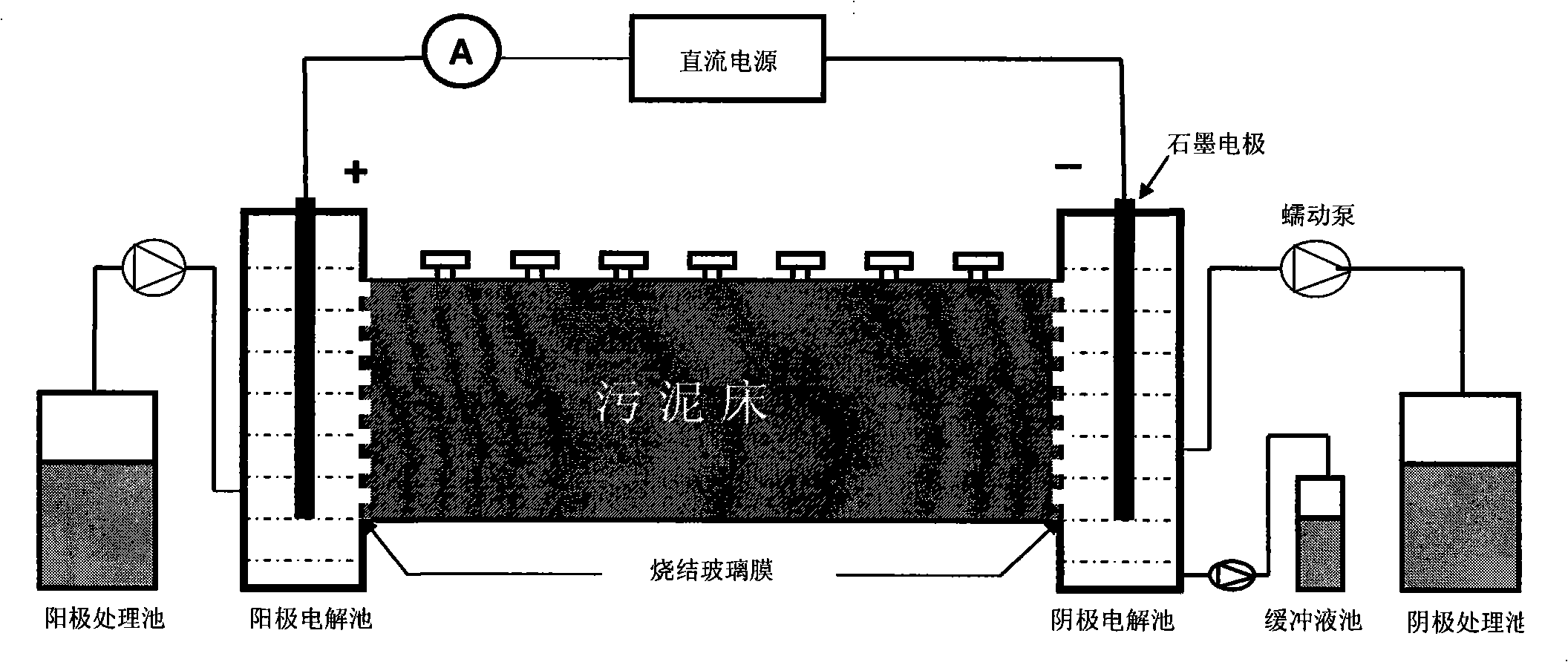

[0025] The sludge used in the experiment was taken from Shanghai Quyang Wastewater Treatment Plant, and the nature of the sewage is domestic sewage. Basic characteristics of sludge: pH 6.52; Cu 212mg.kg -1 ;Zn 1487mg.kg -1 ;Cr 25.7mg.kg -1 ;Pb78.2mg.kg -1 ;Ni 24.8mg.kg -1 ;Cd 16.8mg.kg -1 (The above are all based on dry matter). The electrodynamic restoration device used was modified and optimized on the basis of referring to the soil electric restoration device designed by the Nanjing Soil Institute of the Chinese Academy of Sciences ( figure 1 ), the bed body is made of plexiglass tube, the inner diameter is 20cm, the bed body length is 50cm, and the whole sludge bed can be filled with about 4kg sludge. Dig 15 and small holes equidistantly above the sludge bed to facilitate the measurement of the voltage drop along different stages of the bed. The electrode is made of ordinary graphite material with a diameter of 8 mm. The voltage is applied through a DC voltage stabi...

Embodiment 2

[0029] The sludge from the sewage plant and the electric restoration device used in the experiment are as in Example 1.

[0030] The test sludge was pretreated before treatment, the moisture content was 82.3%, and the sludge was treated with 0.01N HNO 3 After acidification, pH = 4.1. At the same time, in the pretreatment process, PESA solution (the molar ratio of PESA to the total amount of heavy metals in the sludge is 4:1) was also added, and the sludge was fully mixed by stirring. Put the pretreated sludge into the sludge bed and start electrokinetic treatment. By adjusting the voltage, the bed body is maintained at about 1.2V / cm, and the actual voltage gradient fluctuates between 1.21 and 1.24V / cm. As in Example 1, during operation, the pH of the cathodic electrolytic cell and the treatment pool were adjusted by 0.1 mol / L acetic acid buffer to maintain the pH value of the cathodic electrolytic cell at around 5-6.

[0031] After 15 days of running time, the sludge from th...

Embodiment 3

[0033] In order to further verify the effect of electrodynamic restoration technology on the removal of heavy metals in sludge, the present invention also takes industrial sewage treatment plant sludge with high heavy metal content as the treatment object. The industrial sludge tested was taken from Shanghai Taopu Industrial Wastewater Treatment Plant. The basic characteristics of the sludge: pH 8.07; Cu 4258mg.kg -1 ;Zn 13879mg.kg -1 ;Cr 420mg.kg -1 ;Pb 68.3mg.kg -1 ;Ni 621mg.kg -1 ;Cd 578mg.kg -1 (The above are all based on dry matter). The electric restoration device used in the experiment is as in Example 1.

[0034] The test sludge was pretreated before treatment, the water content was 84.7%, and the sludge was treated with 0.01N HNO 3 After acidification, pH = 3.9. At the same time, in the pretreatment process, a PESA solution (the molar ratio of PESA to the total amount of heavy metals in the sludge is 5:1) was also added, and the sludge was fully mixed by stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com