Method for preparing aflatoxin G1 artificial antigen

An aflatoxin and artificial antigen technology, which is applied to the preparation methods of peptides, chemical instruments and methods, animal/human proteins, etc., can solve the problems of lack of aflatoxin G1 artificial antigen preparation method, etc., and is suitable for large-scale production. And the effect of popularization and application, good stability, simple and feasible preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

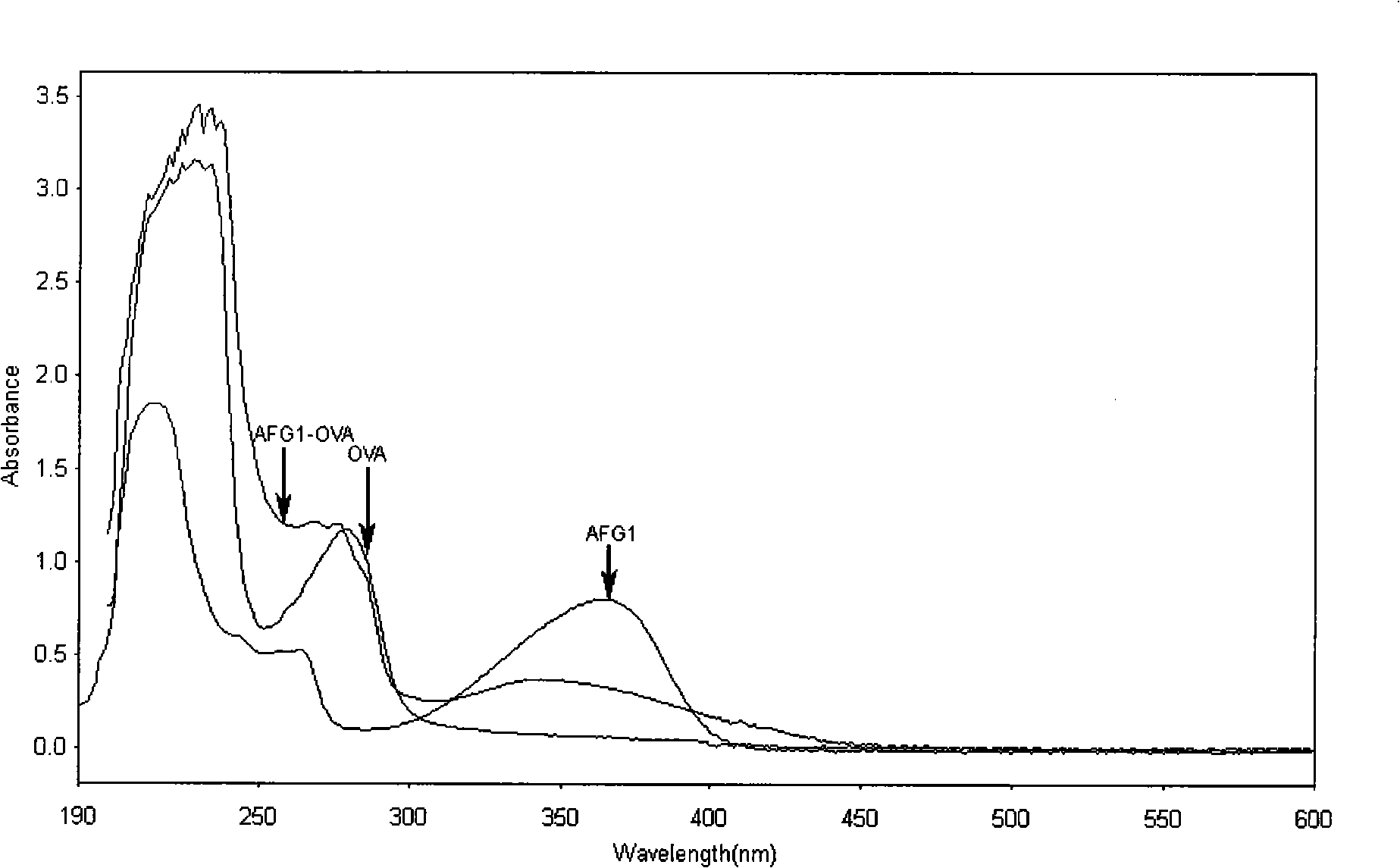

Image

Examples

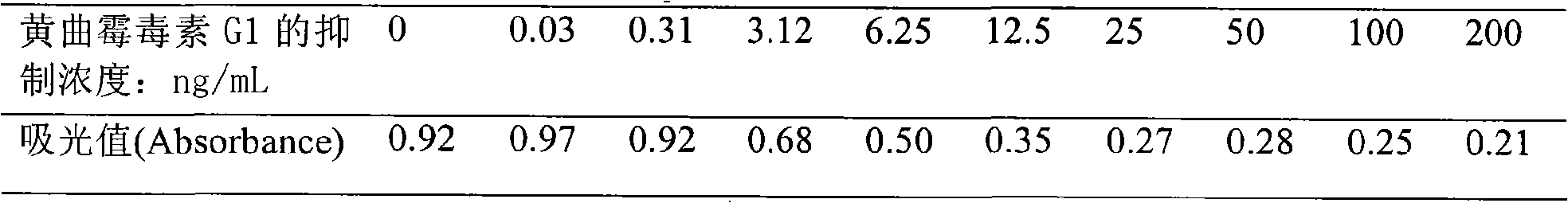

Embodiment 1

[0015] 1) get commercially available purity (by weight) and be that 9.86 milligrams of m-chloroperoxybenzoic acid of 85% are dissolved in 1 milliliter of dichloromethane, and use 0.1 moles of 1 milliliter of every liter of pH7.0 phosphate buffer in Wash 4 times in the separating funnel; Weigh 2 mg of aflatoxin G1 and dissolve it in 1 ml of dichloromethane, and add 1 ml of 0.1 moles of pH7.2 per liter of phosphate buffer; the above m-chloroperoxybenzene Mix formic acid solution and aflatoxin G1 solution, and stir magnetically at 22°C for 80 minutes; leave the final reaction solution at room temperature, discard the upper aqueous phase after layering, and keep the organic phase, which is the aflatoxin Solution of G1 epoxide in dichloromethane.

[0016] 2) 2 milliliters of the organic phase retained in the above steps 1) was added to 4.0 milliliters of phosphate buffered saline solution containing 13.6 milligrams of bovine serum albumin at pH 7.2, and the formed two-phase system ...

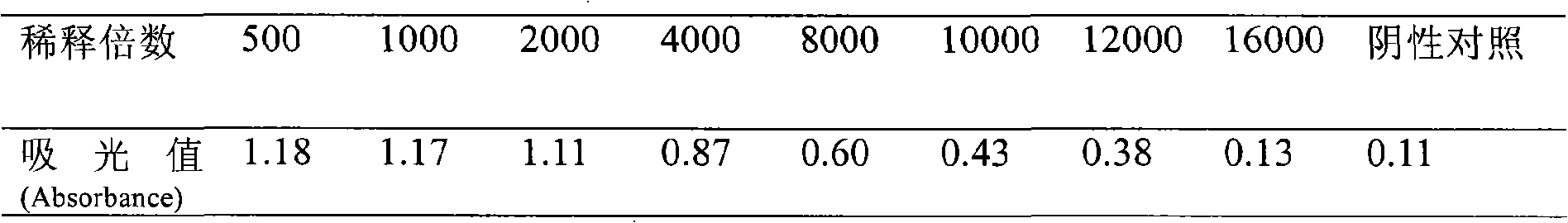

Embodiment 2

[0019] 1) get commercially available purity (by weight) and be that 9.39 milligrams of m-chloroperoxybenzoic acid of 85% are dissolved in 1 milliliter of dichloromethane, and use equal volume of 0.1 mole per liter of pH7.0 phosphate buffer in Wash 3 times in the separating funnel; Take 2mg aflatoxin G1 and dissolve in 1 milliliter of dichloromethane, and add 0.1 moles of 1 milliliter of every liter of pH7.2 phosphate buffer; The solution was mixed with the aflatoxin G1 solution, and stirred magnetically at 22°C for 100 minutes; the final reaction solution was allowed to stand at room temperature, and the upper aqueous phase was discarded after layering, and the organic phase was kept, which was the aflatoxin G1 Dichloromethane solution of epoxide.

[0020] 2) 2 milliliters of the organic phase retained in the above step 1) was added to 6.0 milliliters of phosphate buffered saline solution containing 13.1 milligrams of ovalbumin at pH 7.2, and the formed two-phase system was ma...

Embodiment 3

[0023] 1) get commercially available purity (by weight) and be that 8.62 milligrams of m-chloroperoxybenzoic acid of 85% are dissolved in 1 milliliter of dichloromethane, and use 0.1 moles of 1 milliliter of every liter of pH7.0 phosphate buffer in Wash 4 times in the separating funnel; Weigh 2 mg of aflatoxin G1 and dissolve it in 1 ml of dichloromethane, and add 1 ml of 0.1 moles of pH7.2 per liter of phosphate buffer; the above m-chloroperoxybenzene Mix formic acid solution and aflatoxin G1 solution, and stir magnetically at 22°C for 80 minutes; leave the final reaction solution at room temperature, discard the upper aqueous phase after layering, and keep the organic phase, which is the aflatoxin Solution of G1 epoxide in dichloromethane.

[0024] 2) 2 milliliters of the organic phase retained in the above step 1) was finally added to 4.0 milliliters of phosphate buffered saline solution containing 12.5 milligrams of bovine serum albumin at a pH of 7.2, and the formed two-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com