Method for continuously vacuum volatilizing and separating azeotrope and device

A technology of vacuum volatilization and azeotrope, applied in the direction of vacuum distillation, etc., can solve the problems of high control level, increase the complexity of the device, increase the equipment cost, etc., and achieve the effect of low heating temperature, convenient operation, and increase of volatilization area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 steps

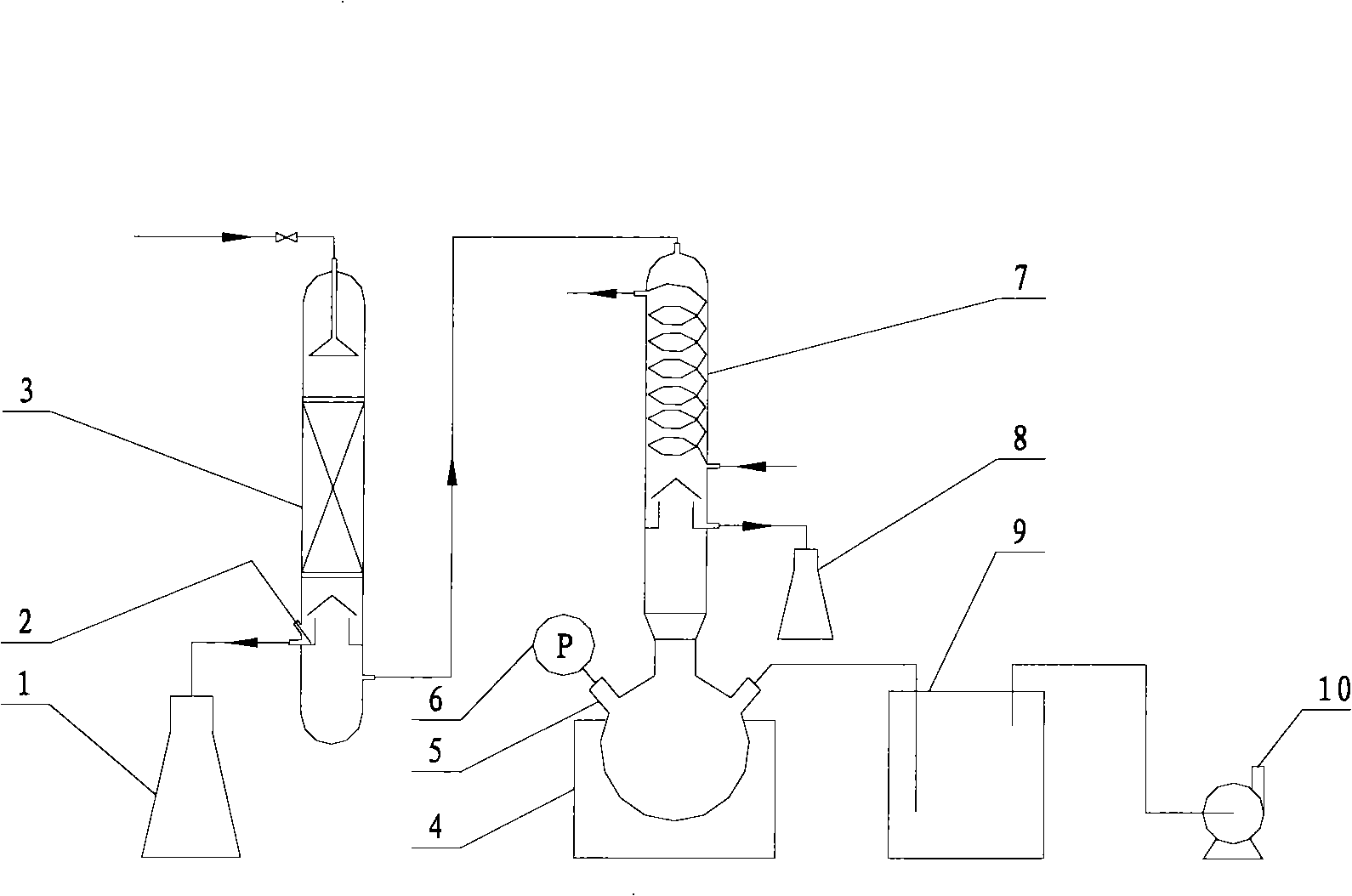

[0031] Connect the glass tower, condenser, vacuum pump and other equipment according to the installation diagram, and seal them well to check the airtightness of the whole system;

[0032] Surround the three-neck flask with crushed ice, so that the gas that cannot be condensed after passing through the coil condenser can be completely condensed here, so as to prevent the gas from being sucked into the vacuum pump and damaging the vacuum pump;

[0033] Wrap the heating tape on the surface of the packing section and connect it with the pressure regulator;

[0034] Add ethanol-water solution with an ethanol mass fraction of 0.94 into the raw material kettle, turn on the condensed water, turn on the vacuum pump, observe the mercury differential pressure meter display, and keep the system at a constant pressure of 13kPa;

[0035] Adjust the heating voltage to heat the packing section. Control the heating temperature t during the experiment 1 20°C, so ...

Embodiment 2

[0039] Embodiment 2 steps

[0040] Connect the glass tower, condenser, vacuum pump and other equipment according to the installation diagram, and seal them well to check the airtightness of the whole system;

[0041] Surround the three-neck flask with crushed ice, so that the gas that cannot be condensed after passing through the coil condenser can be completely condensed here, so as to prevent the gas from being sucked into the vacuum pump and damaging the vacuum pump;

[0042] Wrap the heating tape on the surface of the packing section and connect it with the pressure regulator;

[0043] Add the ethanol-toluene solution with an ethanol mass fraction of 0.65 into the raw material kettle, turn on the condensed water, turn on the vacuum pump, observe the mercury differential pressure meter display, and maintain the system at a constant pressure of 11kPa;

[0044] Adjust the heating voltage to heat the packing section. Control the heating temperature t during the experiment 1...

Embodiment 3

[0048] Embodiment 3 steps

[0049] Connect the glass tower, condenser, vacuum pump and other equipment according to the installation diagram, and seal them well to check the airtightness of the whole system;

[0050] Surround the three-neck flask with crushed ice, so that the gas that cannot be condensed after passing through the coil condenser can be completely condensed here, so as to prevent the gas from being sucked into the vacuum pump and damaging the vacuum pump;

[0051] Wrap the heating tape on the surface of the packing section and connect it with the pressure regulator;

[0052] Add the ethanol-cyclohexane solution with an ethanol mass fraction of 0.25 into the raw material kettle, turn on the condensed water, turn on the vacuum pump, observe the mercury differential pressure meter display, and maintain the system at a constant pressure of 15kPa;

[0053] Adjust the heating voltage to heat the packing section. Control the heating temperature t during the experimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com