Gadolinium thorium oxygen iron arsenic high-temperature superconducting material and preparation thereof

A superconducting material, iron arsenic technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high conducting conductors, etc., can solve the problem of insufficient upper critical magnetic field, limited application range, low superconducting critical temperature, etc. problems, to achieve the effect of being beneficial to superconducting performance, broad application prospects, and good superconducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Combine GdAs, Gd 2 o 3 , ThO 2 , FeAs, and Fe powder and other raw materials are fully mixed according to the molar ratio of Gd, Th, O, Fe, As and other elements in a ratio of 0.8:0.2:1:1:1, uniformly mixed and ground in an argon atmosphere, and then heated in a 400MPa Stamping under pressure to obtain compressed tablets;

[0022] 2) Seal the above tablet in a vacuumed quartz tube, the vacuum degree is better than 0.1Pa, and then put it into a tube furnace for calcination for 36 hours at a calcination temperature of 1453K, and then quickly cool to room temperature to obtain Gd 0.8 Th 0.2 OFeAs bulk.

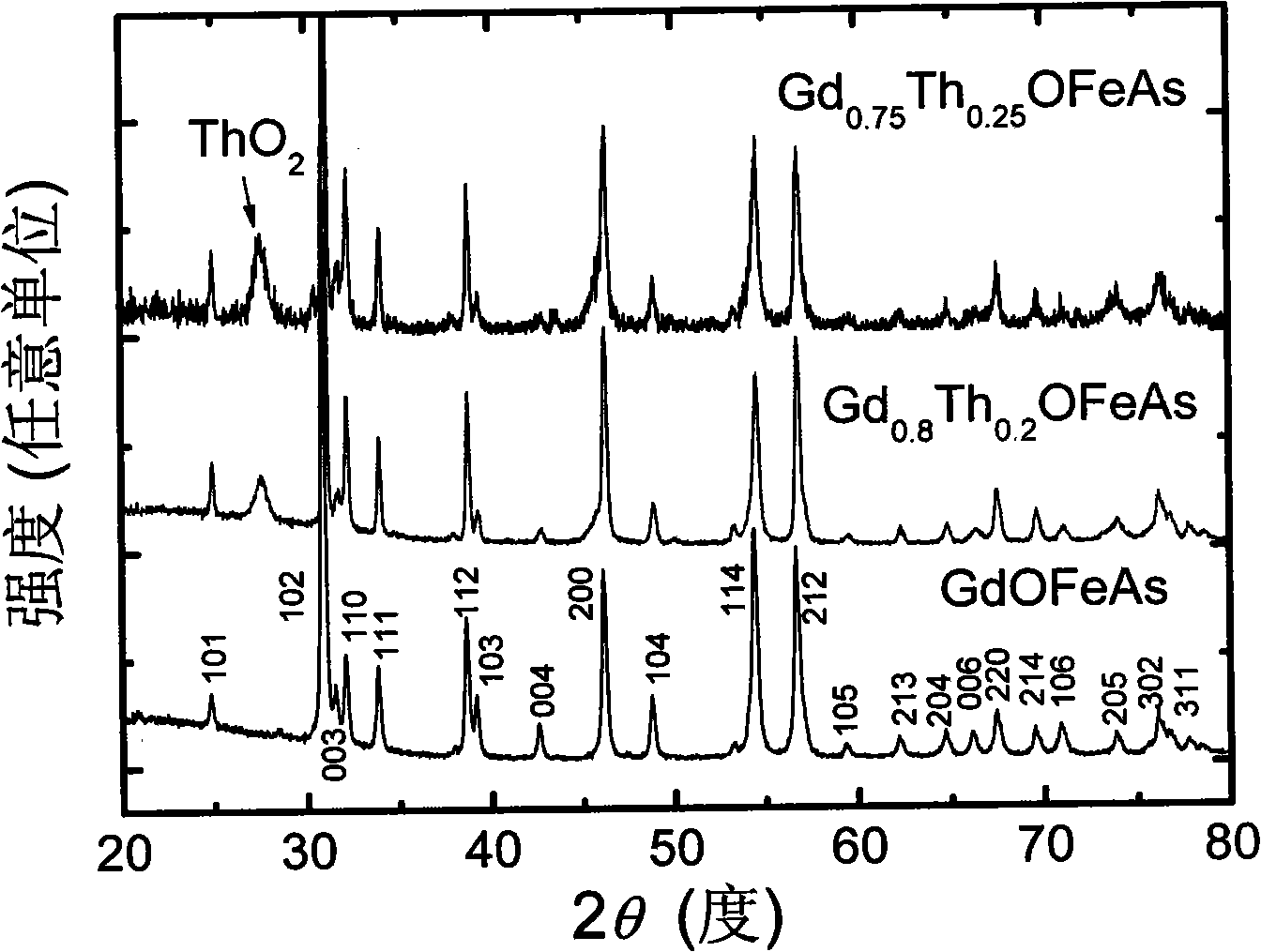

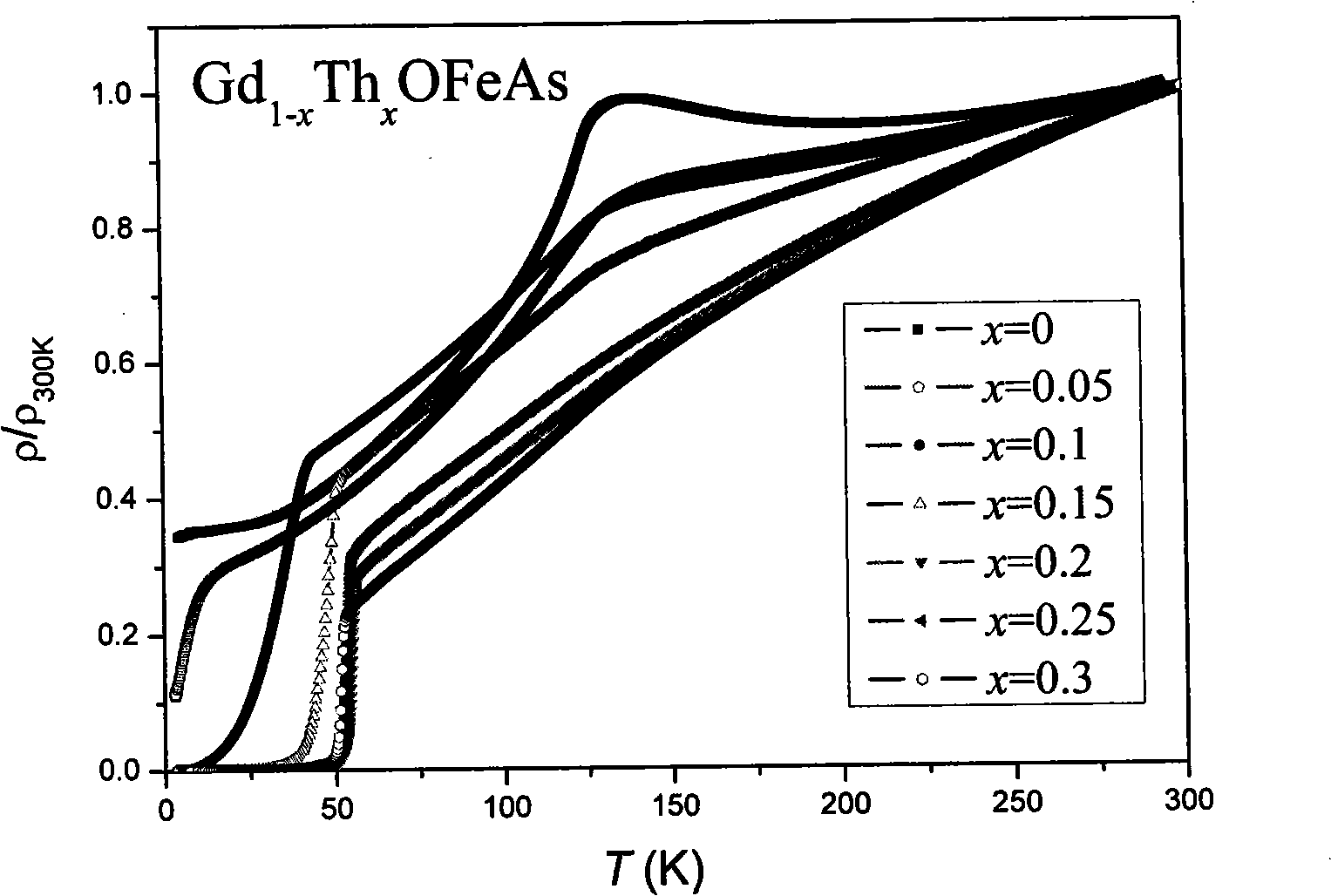

[0023] from figure 1 It can be seen that the main phase of the sample obtained by the above preparation method is Gd with a tetragonal structure (ZrCuSiAs type). 1-x Th x OFeAs compounds. Remove a small amount of residual ThO 2 In addition, all the X-ray diffraction peaks can be well indexed, and the unit cell parameters of the sample are from figure 2 with...

Embodiment 2

[0025] 1) Combine GdAs, Gd 2 o 3 , ThO 2 , FeAs, and Fe powder and other raw materials are fully mixed according to the molar ratio of Gd, Th, O, Fe, As and other elements in the ratio of 0.75:0.25:1:1:1, uniformly mixed and ground in an argon atmosphere, and then heated in a 400MPa Stamping under pressure to obtain compressed tablets;

[0026] 2) Seal the above tablet in a vacuumed quartz tube, the vacuum degree is better than 0.1Pa, and then put it into a tube furnace for calcination for 48 hours at a calcination temperature of 1473K, and then quickly cool to room temperature to obtain Gd 0.75 Th 0.25 OFeAs bulk.

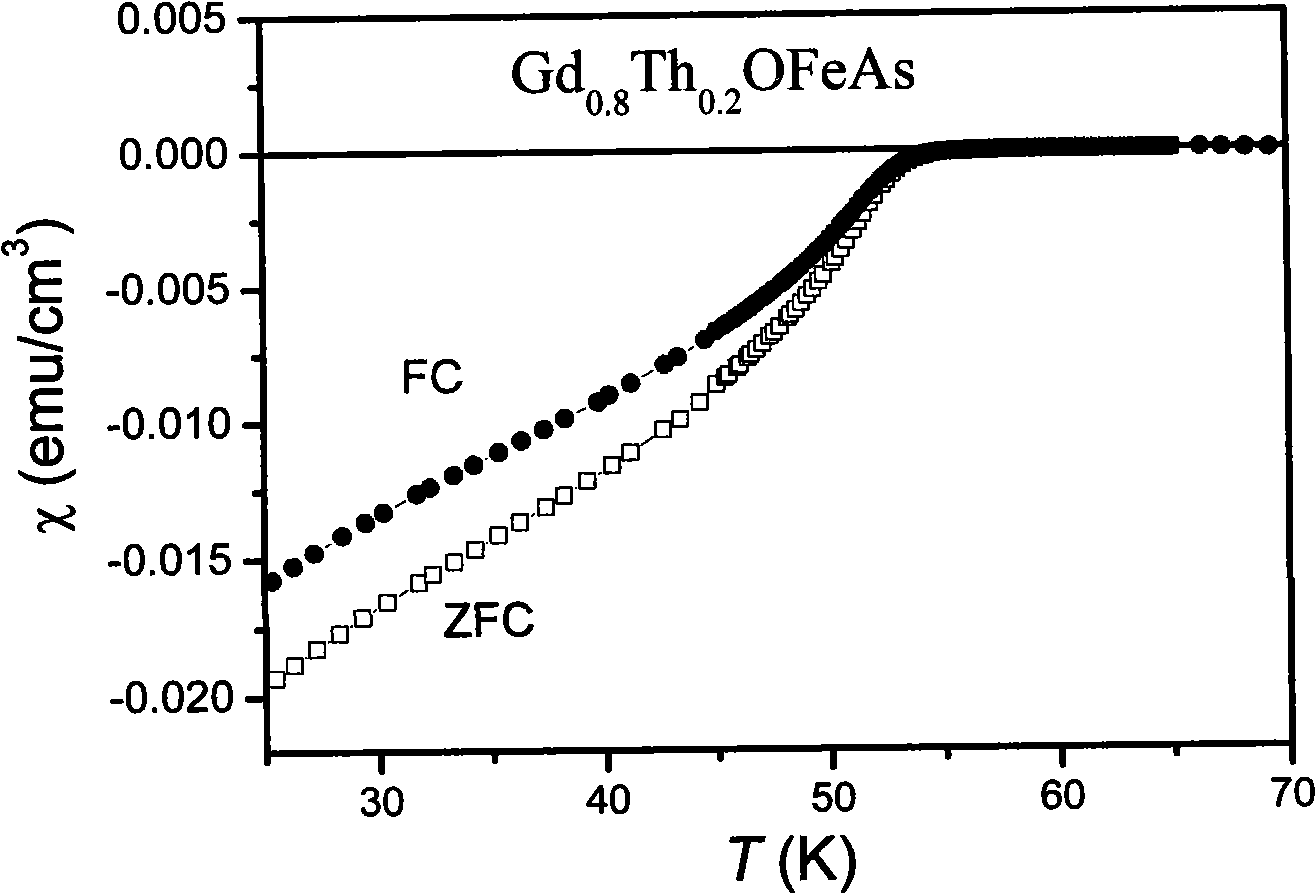

[0027] from figure 1 It can be seen that the main phase of the sample obtained by the above method is a superconductor of gadolinium thorium iron arsenic, and the main impurity phase is ThO 2 , the unit cell parameters of the samples are shown in Table 1; from figure 2 It can be known that the resistivity of the synthesized gadolinium thorium iron arsenic ...

Embodiment 3-6

[0029] Table 1 is Gd 1-x Th x Raw material ratio, sintering temperature, superconducting critical temperature and unit cell parameters of OFeAs(0.05≤x≤0.30) single-phase samples. Table 1

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com