Method for construction of high power LED multilayer gradient material cooling channel

A heat dissipation channel and gradient material technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as failing to meet the high-efficiency heat dissipation requirements of high-power LEDs, reduce package thermal resistance and thermal mismatch, and improve Heat dissipation capacity and stability, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

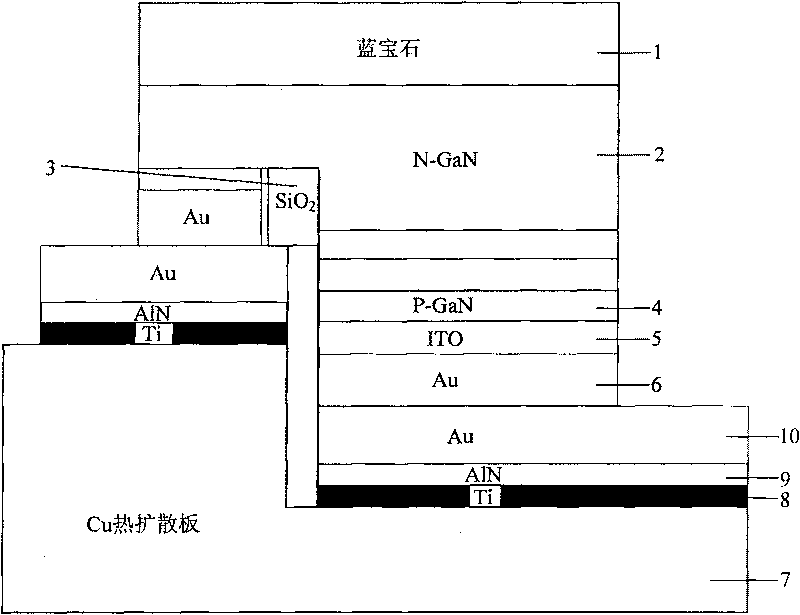

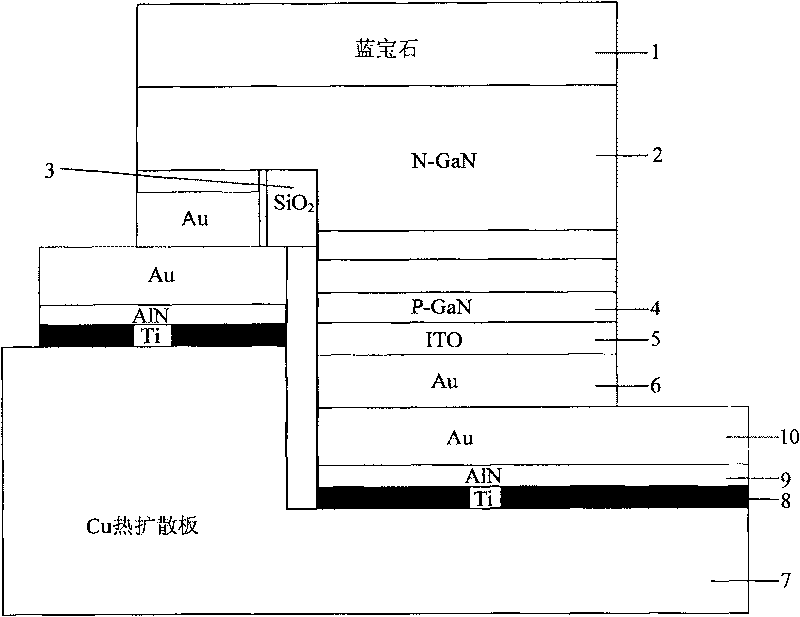

[0018] The invention adopts the Au-Au-AlN-Ti multilayer material with high thermal conductivity and gradient change of thermal expansion coefficient to prepare the heat dissipation channel between the LED and the Cu rapid thermal diffusion plate, which greatly reduces the package thermal resistance and thermal mismatch, and improves the heat dissipation capacity of the device and stability.

[0019] The following is a detailed description of the preparation process of the pure gold bonded flip-chip LED chip:

[0020] First, use ICP (Inductively Coupled Plasma Etching) or IBE (Ion Beam Etching) equipment to dry-etch the GaN-based LED epitaxial wafer to form an L-shape, exposing the N-GaN layer 2 mesa, in which the etching mask layer 3 is photoresist or SiO 2 .

[0021] After the mesa of the N-GaN layer 2 is exposed, a layer of ITO (indium tin oxide) current spreading layer 5 is evaporated on the surface of the P-GaN layer 4; then the P and N electrodes are evaporated by magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com