Trimetazidine hydrochloride dispersible tablet and preparation method thereof

A technology of trimetazidine hydrochloride and dispersible tablets, which is applied in the field of trimetazidine hydrochloride dispersible tablets and its preparation, can solve problems such as difficulty in swallowing drugs, sudden onset of angina pectoris, etc., and achieve rapid disintegration, improved bioavailability, The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

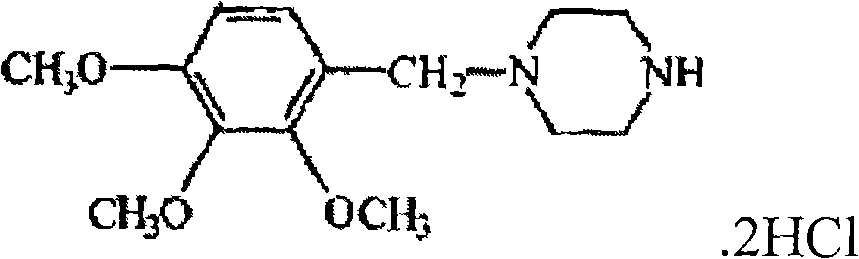

Image

Examples

Embodiment 1

[0024] Embodiment 1: trimetazidine hydrochloride dispersible tablet

[0025] Trimetazidine Hydrochloride 20g

[0026] Microcrystalline Cellulose 100g

[0027] 20g pregelatinized starch

[0028] Hypromellose (additional) 10g

[0029] Stevia 6.0g

[0030] 2% (w / v) hypromellose solution (prepared with 50% ethanol) appropriate amount

[0031] Crospovidone (additional) 10g

[0032] Magnesium Stearate 1.5g

[0033]

[0034] A total of 1000 trimetazidine hydrochloride dispersible tablets were made

[0035] Preparation process: pass the trimetazidine hydrochloride raw material through a 100-mesh sieve, pass the rest of the auxiliary materials through a 80-mesh sieve, take the formula amount of trimetazidine hydrochloride, filler microcrystalline cellulose and pregelatinized starch, flavoring agent steviol and The added part of the disintegrating agent hypromellose is fully mixed evenly; wet granulation with 2% hypromell...

Embodiment 2

[0036] Embodiment 2: trimetazidine hydrochloride dispersible tablet

[0037] Trimetazidine Hydrochloride 20g

[0038] Microcrystalline Cellulose 115g

[0039] Starch 30g

[0040] Hypromellose (additional) 15g

[0041] Aspartame 2.0g

[0042] 2% (w / v) hypromellose solution (prepared with 50% ethanol) appropriate amount

[0043] Croscarmellose sodium (extra) 15g

[0045]

[0046] A total of 1000 trimetazidine hydrochloride dispersible tablets were made

[0047] The trimetazidine hydrochloride raw material was passed through a 100-mesh sieve, and the rest of the auxiliary materials were passed through a 80-mesh sieve, wet granulated, and compressed into dispersible tablets. The specific preparation process was the same as in Example 1.

Embodiment 3

[0048] Embodiment 3: trimetazidine hydrochloride dispersible tablet

[0049] Trimetazidine Hydrochloride 20g

[0050] Microcrystalline Cellulose 100g

[0051] Lactose 35g

[0052] Hypromellose (additional) 12g

[0053] Stevia 00000000 6.0g

[0054] 2% (w / v) hypromellose solution (prepared with 50% ethanol) appropriate amount

[0055] Croscarmellose sodium (extra) 15g

[0056] Magnesium Stearate 1.5g

[0057]

[0058] A total of 1000 trimetazidine hydrochloride dispersible tablets were made

[0059] The trimetazidine hydrochloride raw material is passed through a 100 mesh sieve, the rest of the auxiliary materials are passed through an 80 mesh sieve, wet granulated, and compressed into dispersible tablets, the specific preparation process is the same as in Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com