Aluminum alloy for preparing hydrogen by hydrolytic decomposition and preparation thereof

A technology for producing hydrogen and aluminum alloys by hydrolysis, applied in the production of hydrogen and other directions, can solve the problems of strong corrosiveness and slow reaction of lye, and achieve the effects of simple reaction, reduced preparation cost and accelerated hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

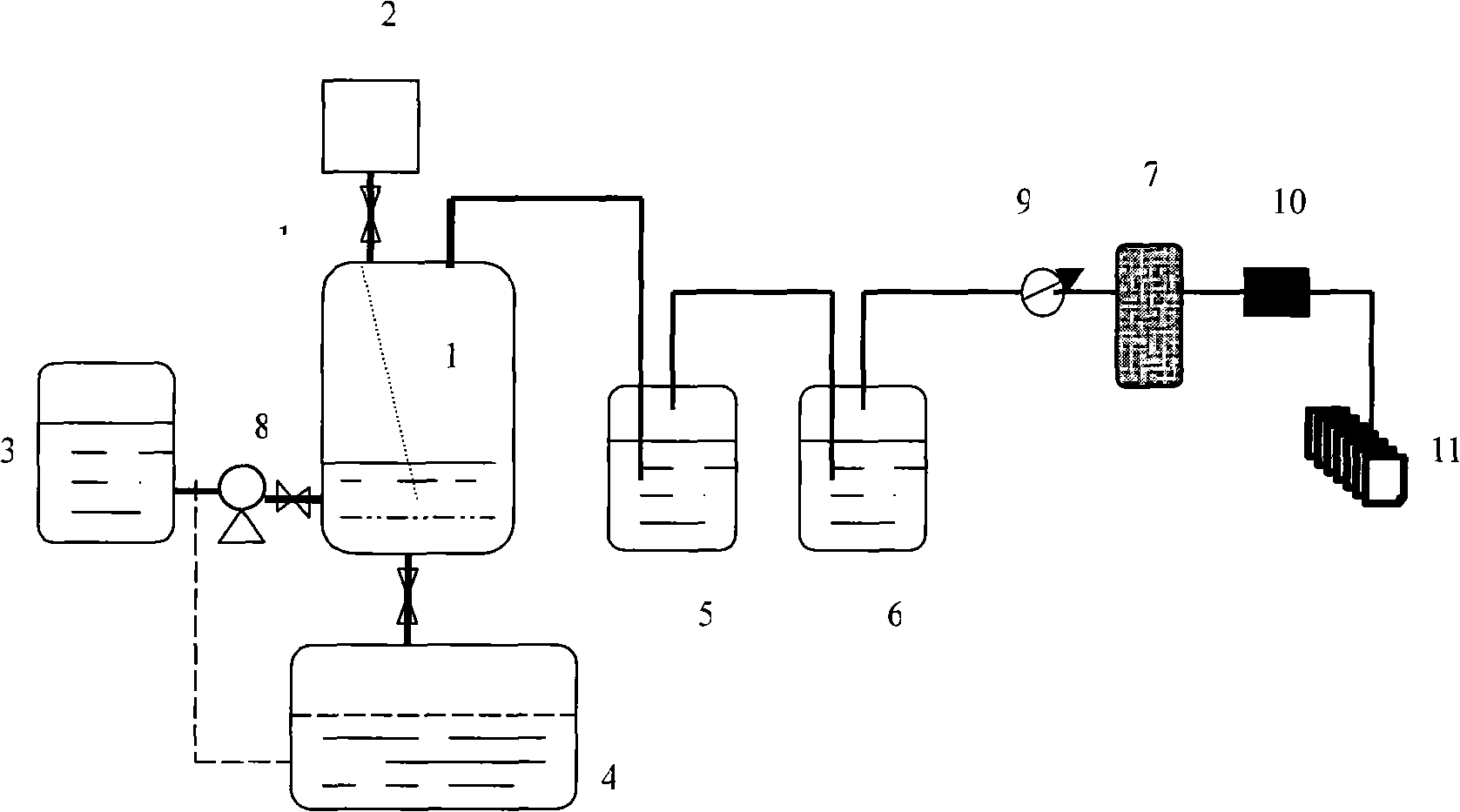

Method used

Image

Examples

Embodiment 1

[0029] The mechanical ball milling method is adopted, the raw material used is powder, the particle size is between 200um-300um, under the protection of argon, the ball-to-material ratio is 15:1, the ball milling time is 12h, and the rotation speed is 450r / min. Two kinds of aluminum alloys were prepared by mixing according to different stoichiometric ratios.

[0030] The composition of aluminum alloy 1 is as follows: aluminum matrix, 80wt%; metal bismuth, 10wt%; low melting point metal material (zinc powder, particle size 200um, 2wt%) and hydride (calcium hydride, 150um, 8wt%)

[0031] The composition of aluminum alloy 2 is as follows: aluminum matrix, 85wt%; Metal bismuth, 8wt%; Low melting point metal material (indium powder, particle diameter 150um, 2wt%; Tin powder, particle diameter 100um, 3wt%) and hydride (magnesium hydride , particle size 100um, 2wt%) total 7wt%.

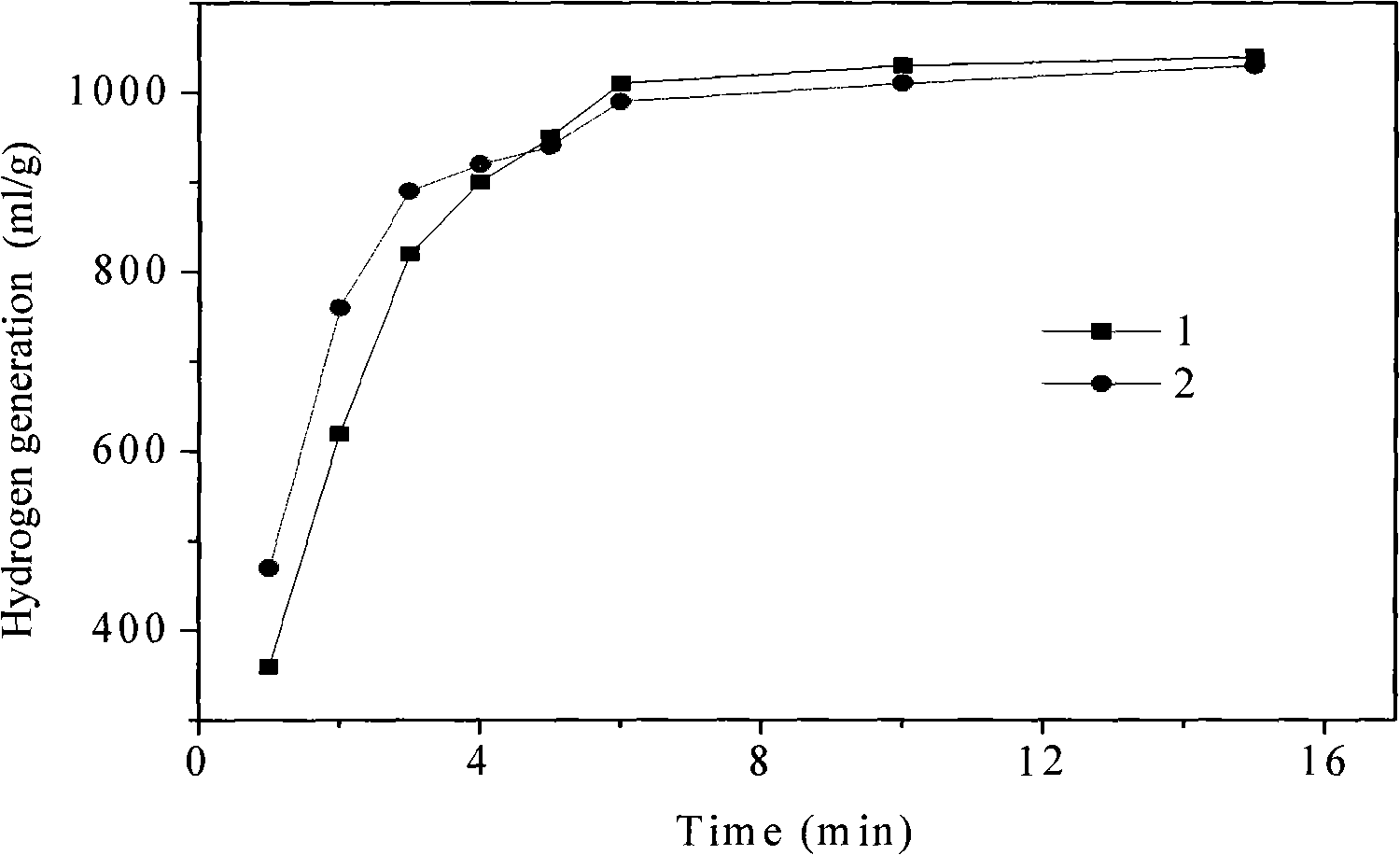

[0032] The prepared aluminum alloy can react with water at normal temperature (such as figure 1 Shown),...

Embodiment 2

[0034] The mechanical ball milling method is adopted, the raw material used is powder, the particle size is between 100um-200um, under the protection of argon, the ball-to-material ratio is 15:1, the ball milling time is 12h, and the rotation speed is 450r / min. Aluminum alloy 3 was prepared by mixing according to different stoichiometric ratios.

[0035] The composition of the aluminum alloy is as follows: aluminum matrix, 80wt%; metal bismuth, 8wt%; low melting point metal material (lead particle, 4wt%; gallium, 2wt%) and soluble salt (salt NaCl, 6wt%) The total is 12wt%.

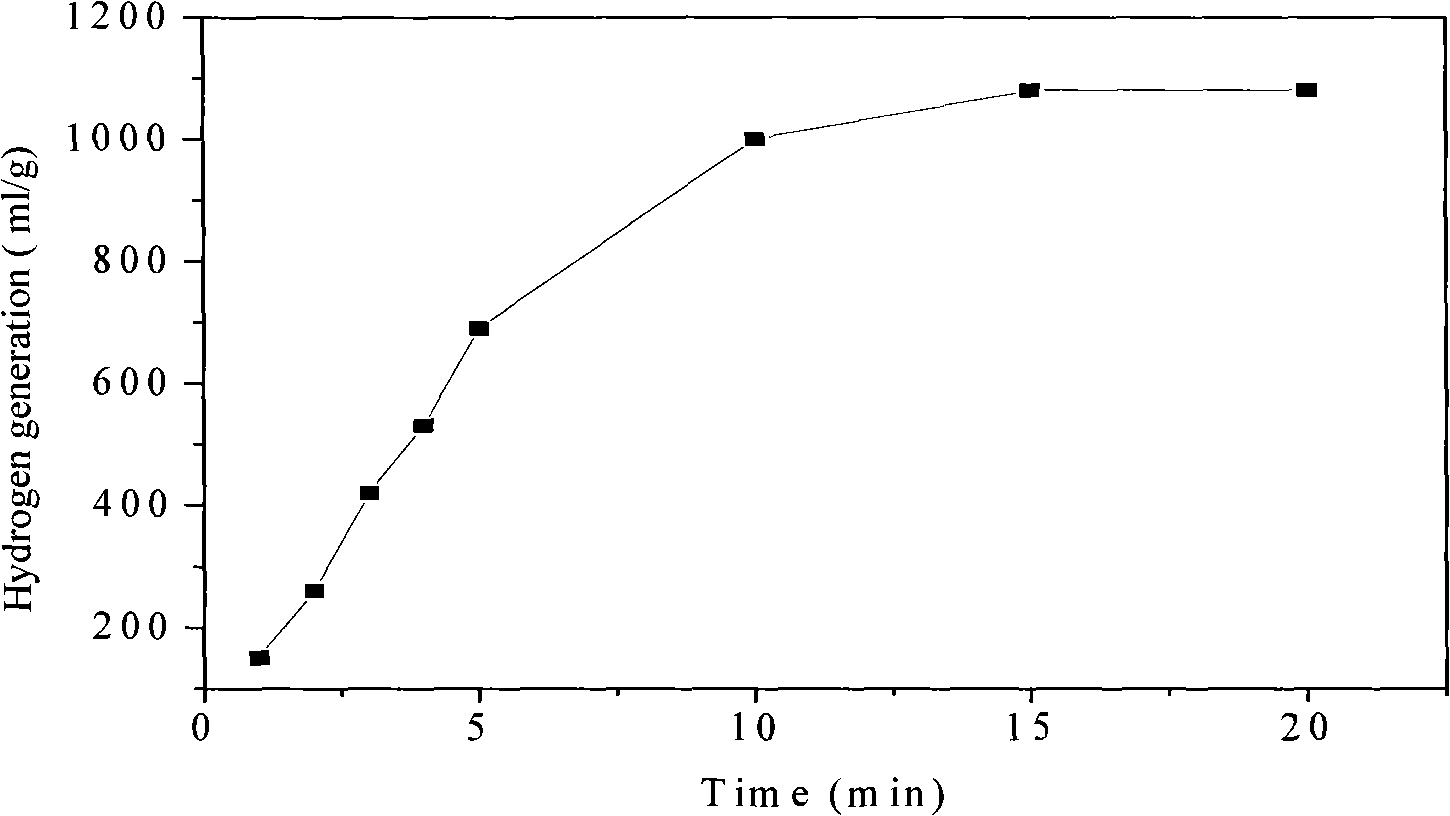

[0036] The prepared aluminum alloy can react with water at normal temperature (such as figure 2 Shown), its reaction rate is very fast, can produce a large amount of hydrogen, and reaches the maximum value in about 15min; The reaction is an exothermic reaction, which can provide moist hydrogen for the fuel cell. The reaction product is black, does not stick to the wall, and is easy to clean.

Embodiment 3

[0038] The difference from Example 1 is that the raw material used is powder, the particle size is between 1um-200um, the mechanical ball milling method is adopted, under the protection of argon, the ball-to-material ratio is 100:1, the ball milling time is 60h, and the rotating speed is 300r / min. Mix according to different stoichiometric ratios to prepare aluminum alloys 4-10.

[0039] The composition of aluminum alloy 4 is as follows: aluminum matrix, 50wt%; metal bismuth, 45wt%; low melting point metal material (tin Sn, 2wt%) and water-soluble compound (barium oxide BaO, 3wt%) total 5wt%.

[0040] The composition of aluminum alloy 5 is as follows: aluminum matrix, 90wt%; metallic bismuth, 8wt%; low melting point metal material (0wt%) and water-soluble compound (potassium hydride KH, 2wt%) totaling 2wt%.

[0041] The composition of aluminum alloy 6 is as follows: aluminum matrix, 70wt%; metal bismuth, 13wt%; low melting point metal material (magnesium powder Mg, 5wt%) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com