Doped graphene and method for preparing same

A graphene and doping element technology is applied in the field of doped graphene and its preparation, and achieves the effects of good quality and convenient operation of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, preparation nitrogen-doped graphene

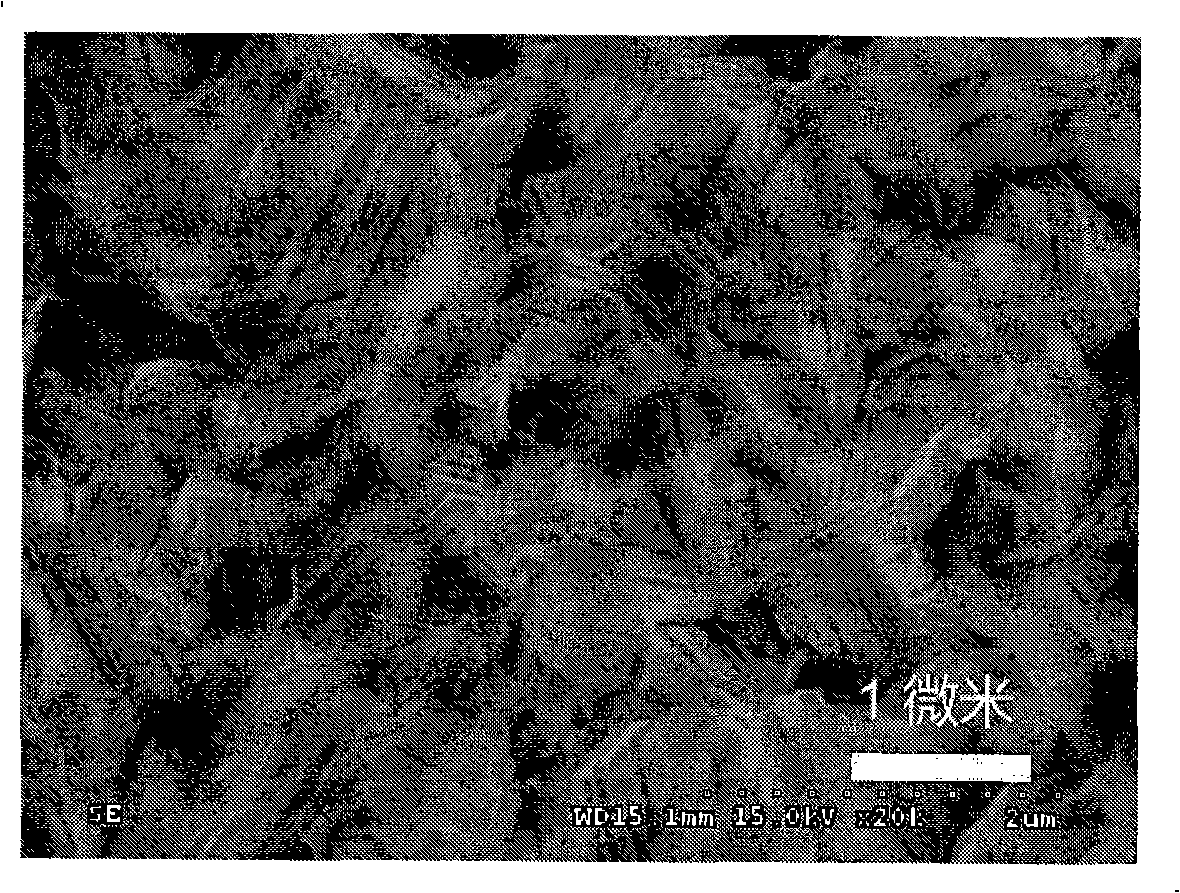

[0036] In the first step, the silicon substrate is ultrasonically cleaned with deionized water, ethanol, and acetone in sequence, and then dried in an oven, and then through physical vapor deposition technology (that is, placing the quartz tube with zinc sulfide powder in a tubular electric furnace and heating it to 950 Celsius, feed 100sccm of argon as a carrier gas, zinc sulfide will be deposited on the silicon chip placed in the low temperature zone) Deposit a layer of zinc sulfide with a thickness of about 100 nanometers on the surface of the silicon substrate as a catalyst (scanning electron microscope photo Such as figure 2 shown);

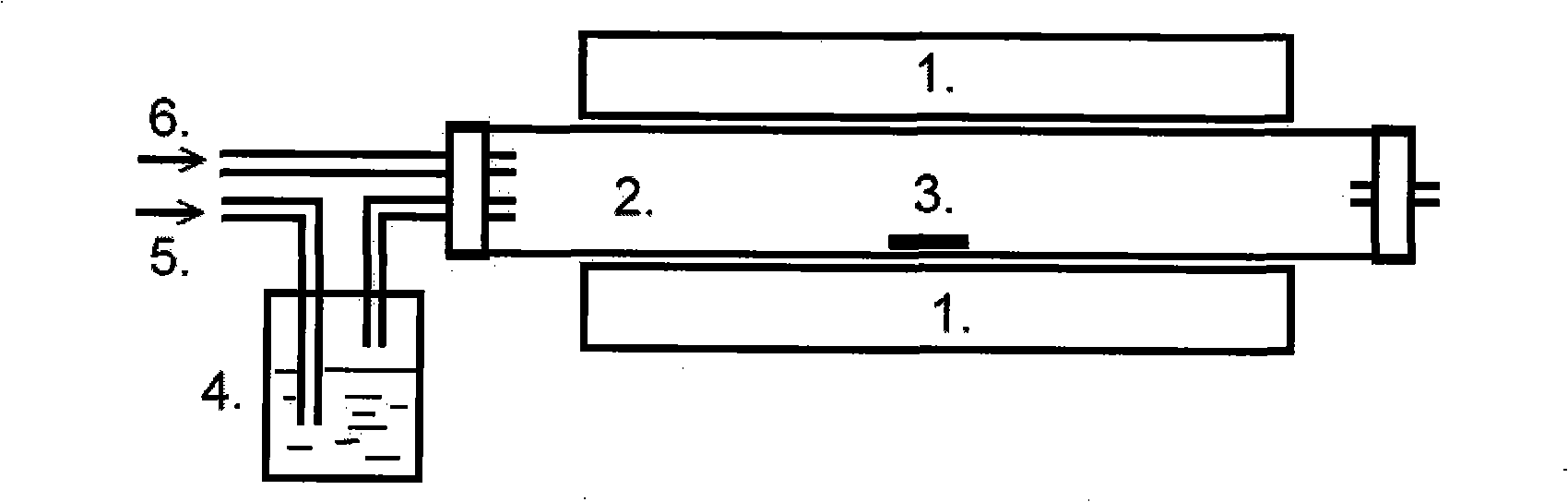

[0037] In the second step, the substrate deposited with zinc sulfide is placed in the middle of a clean quartz tube, and the quartz tube is placed in the electric furnace so that the middle of the quartz tube is located in the central area of the electric furnace, and then 100 sc...

Embodiment 2

[0041] Embodiment 2, prepare nitrogen-doped graphene

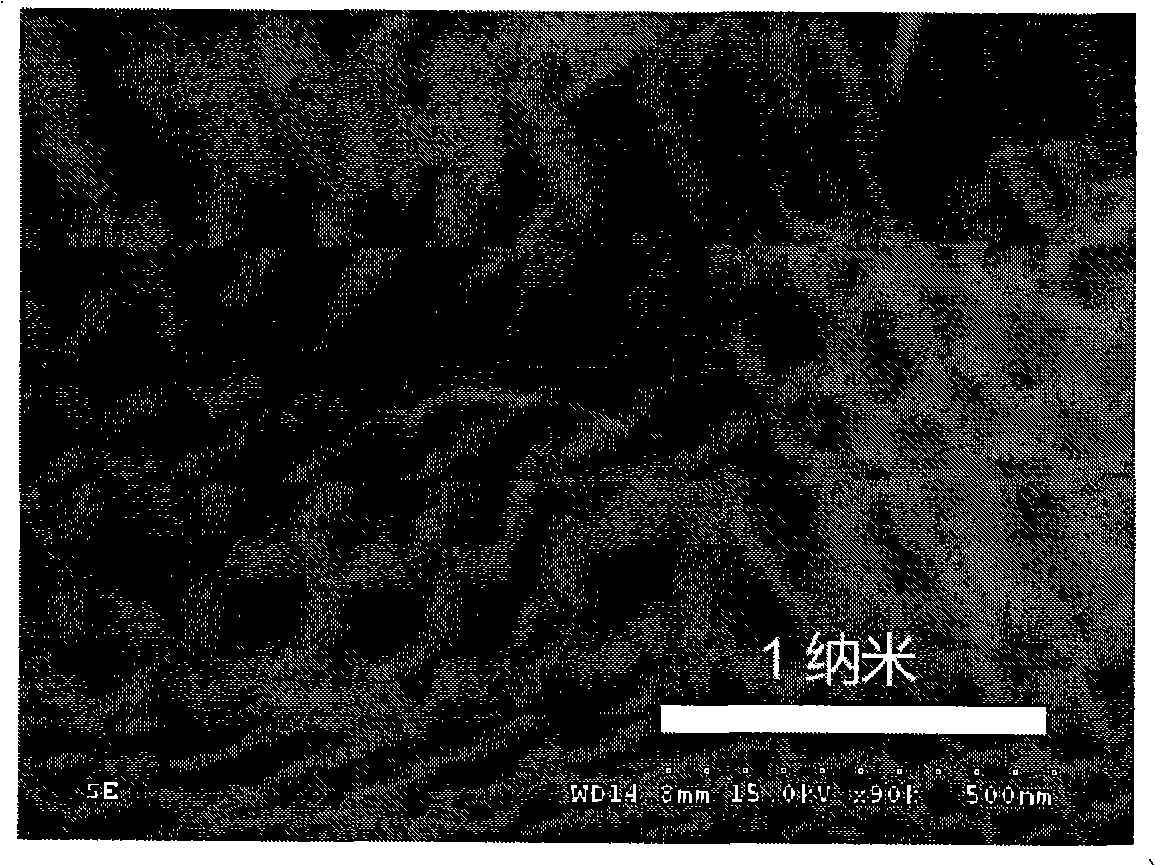

[0042] The preparation method is basically the same as in Example 1, except that the first step adopts the vacuum thermal evaporation method (evaporating by a vacuum coater) to deposit a layer of silver with a thickness of 30 nanometers on the silicon substrate surface as a catalyst; the fifth step Place the substrate deposited with nitrogen-doped graphene in a quartz tube, and evacuate to 0.1 Torr at the same time, raise the temperature of the tube furnace where the quartz tube is placed to 1000°C, close the tube furnace after 30 minutes of treatment, and slowly cool down to room temperature . The scanning electron microscope photo after the fifth step processing is as follows Figure 8 As shown, the formation of two-dimensional film-like doped graphene can be observed from the figure.

Embodiment 3

[0043] Embodiment 3, preparation nitrogen-doped graphene

[0044] The preparation method is basically the same as in Example 1, except that the first step adopts a vacuum thermal evaporation method (evaporation by a vacuum coater) to deposit a layer of 30 nanometer silver on the surface of a silicon substrate as a catalyst; the third step is when When the temperature in the central area of the electric furnace reaches 750°C, at this time, pyridine is passed into the carrier gas as a carbon source and a nitrogen source, and the reaction begins; the fourth step is to stop feeding pyridine after the reaction has been carried out for 10 minutes, and turn off the electric furnace at the same time, and continue A gas mixture of 100 sccm hydrogen and 100 sccm argon was introduced to bring the temperature down to room temperature. The fifth step is to place the substrate deposited with doped graphene in a quartz tube, and at the same time evacuate to 0.1 Torr, raise the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com