Early strength polycarboxylic acid high performance dehydragent and method for preparing same

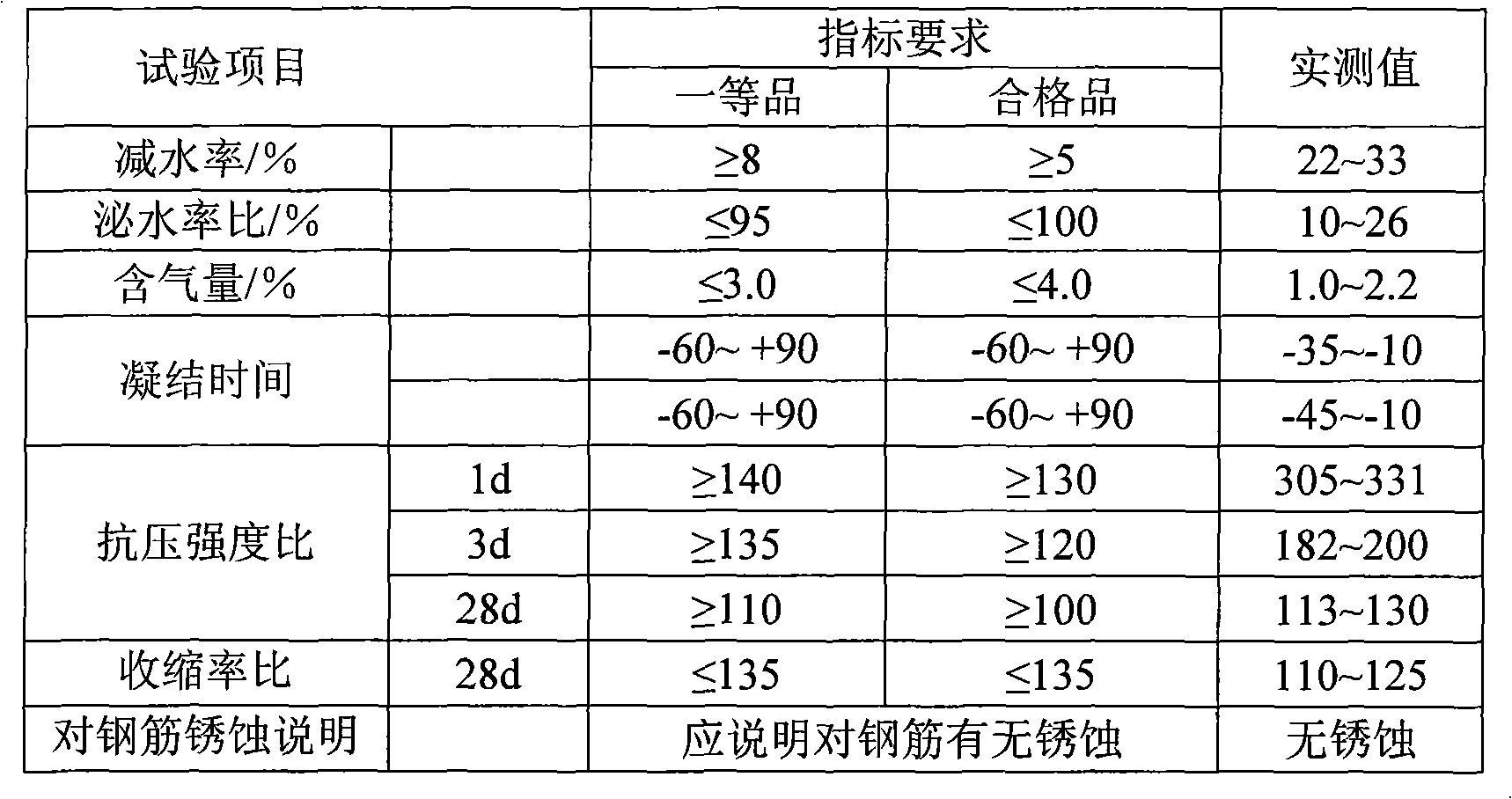

A water-reducing agent and early-strength technology, applied in the field of early-strength polycarboxylate high-performance water-reducing agents, can solve problems such as alkali-aggregate reaction, steel corrosion, etc., and achieve small dosage, high water-reducing rate, and Good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

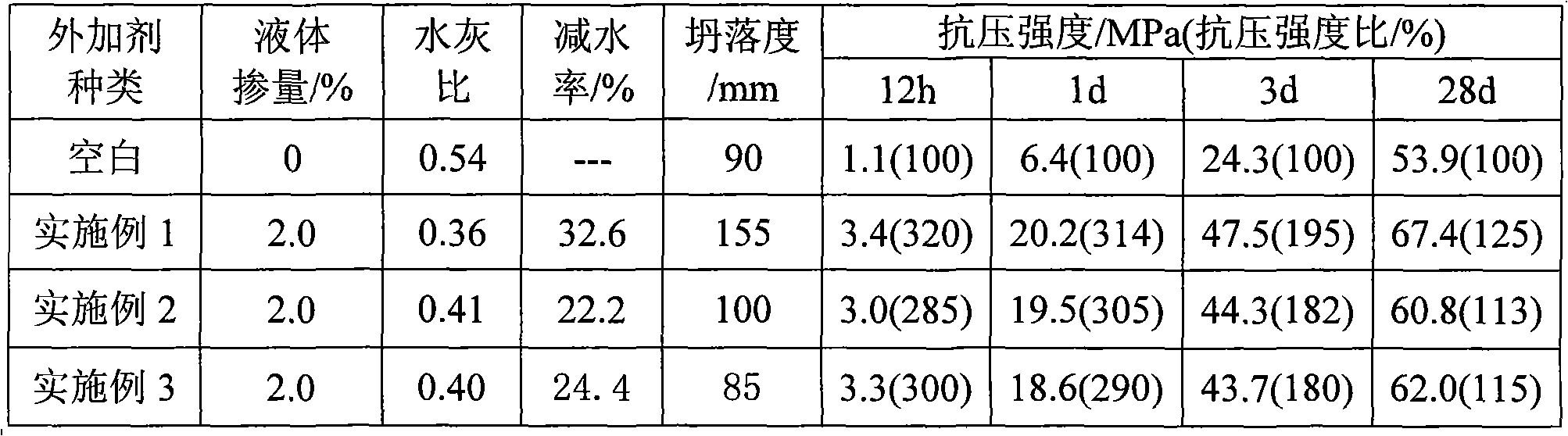

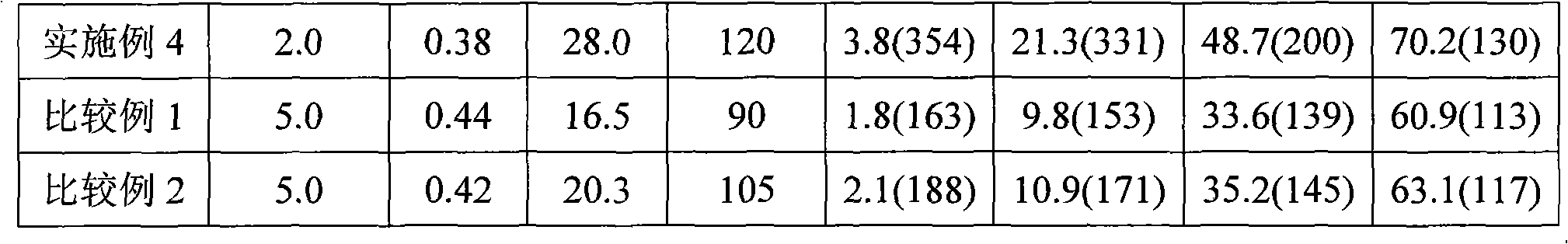

Examples

Embodiment 1

[0017] Carry out the synthesis of acrylic polycarboxylate superplasticizer according to the following steps:

[0018] The first step of esterification reaction: add 100 grams of methoxypolyethylene glycol with a molecular weight of M=1000 in the reaction kettle, heat and stir until fully melted, and control the temperature at 130 ° C, add 0.014 grams of hydroquinone as a polymerization inhibitor, and react After 15 minutes, 14.4 grams of acrylic acid, 1.14 grams of p-toluenesulfonic acid, and 23 grams of cyclohexane were subjected to esterification in sequence; after 4.5 hours of constant temperature reaction, the aqueous agent cyclohexane was removed by vacuuming to obtain a large single Bulk methoxypolyethylene glycol acrylate.

[0019] The second step of polymerization reaction: put the macromonomer obtained in the first step reaction into a four-necked flask, add 150.52 grams of water after heating and melting, raise the temperature to 65°C, stir and dissolve it, and then ...

Embodiment 2

[0022] Synthesize according to Example 1 to obtain an acrylic polycarboxylate superplasticizer, and dilute the resulting 40.0% solution to 20.0%.

[0023] Weigh 40 grams of acrylic polycarboxylate water reducer with a concentration of 20% and place it in a glass container, then add 35.0 grams of water, 1.5 grams of triethanolamine, 2.5 grams of sodium thiocyanate, and 21.0 grams of calcium nitrate in a stirring state. , fully dissolved and left to stand to get early-strength polycarboxylate composite high-efficiency water reducer. Solid content 27%, pH 7.1, clear light brown appearance, dosage 2.0%;

Embodiment 3

[0025] Synthesize according to Example 1 to obtain an acrylic polycarboxylate superplasticizer, and dilute the resulting 40.0% solution to 20.0%.

[0026] Weigh 50 grams of acrylic polycarboxylate water reducer with a concentration of 20% and place it in a stainless steel container, then add 21.5 grams of water, 2.5 grams of triethanolamine, 5 grams of sodium thiocyanate, and 21.0 grams of calcium nitrate in a stirring state. , fully dissolved and left to stand to obtain a light brown and clear early-strength polycarboxylate composite high-efficiency water reducer. Solid content 33.5%, pH 7.2, clear light brown appearance, dosage 2.0%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com