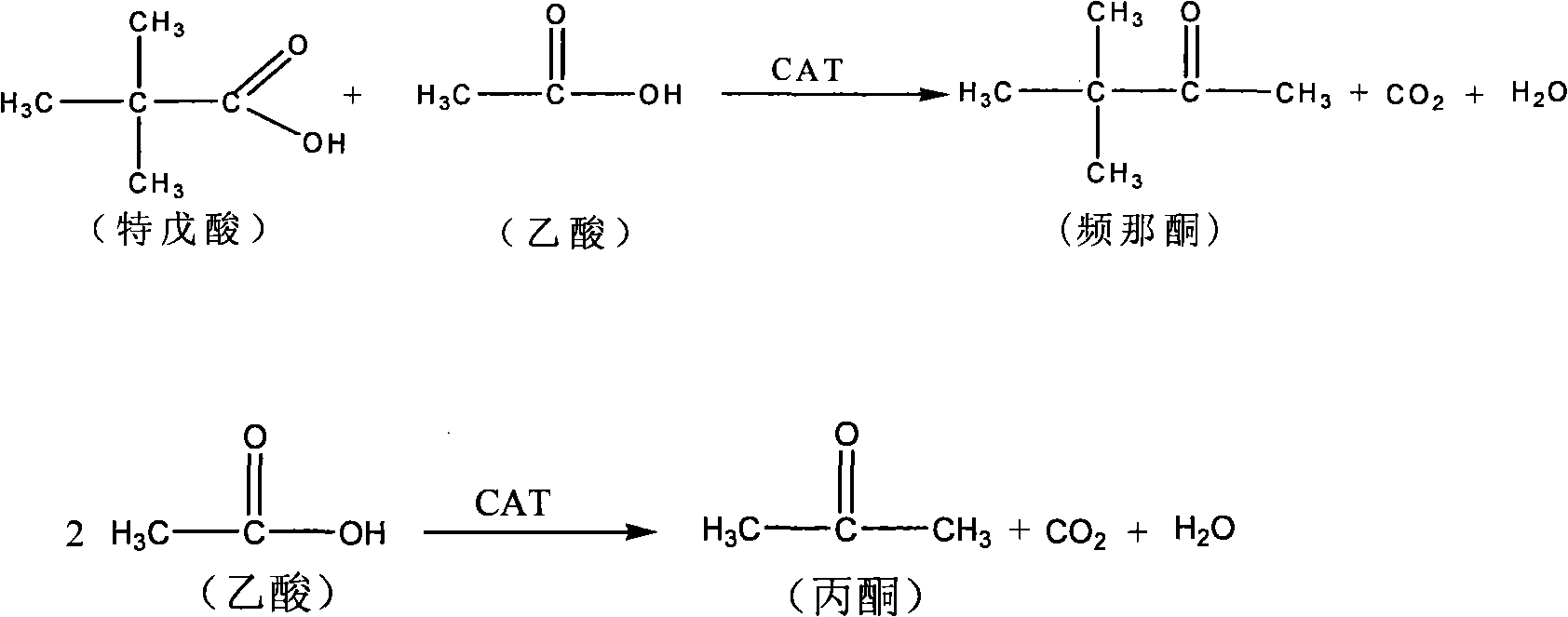

Process for synthesizing 3,3-dimethyl-2-butanone

A technology of dimethyl and butanone, applied in the direction of condensation to prepare carbonyl compounds, organic chemistry, etc., to achieve the effects of simple refining operation, lower reaction temperature, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 114 g of lanthanum nitrate into the dipping kettle, add 100 g of deionized water to prepare a lanthanum nitrate solution for later use. Weigh the specific surface as 150m 2 / g, φ1.5mm strip Al with a pore volume of 0.9ml / g 2 o 3 After drying at 120°C for 4 hours and calcining at 700°C for 4 hours, 80 g of the treated carrier was added to the impregnation kettle, immersed at room temperature for 24 hours, and the remaining liquid was filtered off, dried at 120°C and calcined at 550°C for 4 hours to prepare catalyst A. Add 320g of the mixed solution prepared in a certain proportion to the thin jar, and use a metering pump to enter a fixed-bed reactor equipped with 100g of catalyst A under normal pressure for catalytic decarboxylation reaction. The reaction temperature is 400°C and the space velocity For 0.8h-, the gas phase product obtained by the reaction was condensed, the crude product was collected from the bottom of the condensing device, and a sample was taken...

Embodiment 2-5

[0026] Adopt neodymium nitrate, cerium nitrate, lanthanum nitrate-neodymium nitrate and lanthanum nitrate-cerium nitrate to prepare respectively catalyst B, C, D, E according to the catalyst preparation method of embodiment 1;

[0027] Table 1

[0028] Reality

Embodiment 6

[0030] The test process is the same as in Example 1, adopting a catalyst A 100g fixed-bed reactor to carry out the catalytic decarboxylation reaction, the temperature of reaction is 380°C, and the space velocity is 0.8h-, pivalic acid: acetic acid: water=1: 1.4: 3 , the gas phase product obtained by the reaction is condensed, the crude product is collected from the bottom of the condensing device, and the sample is analyzed. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com