Process for preparing calcium propionate by using japanese pearl oyster conch

A technology of Pinctada martensii and calcium propionate, applied in carboxylate preparation, organic chemistry, etc., can solve the problems of low biological activity of raw materials, hazards of calcium propionate, high production cost, etc., and achieve high-value utilization, Effect of reducing pollution and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

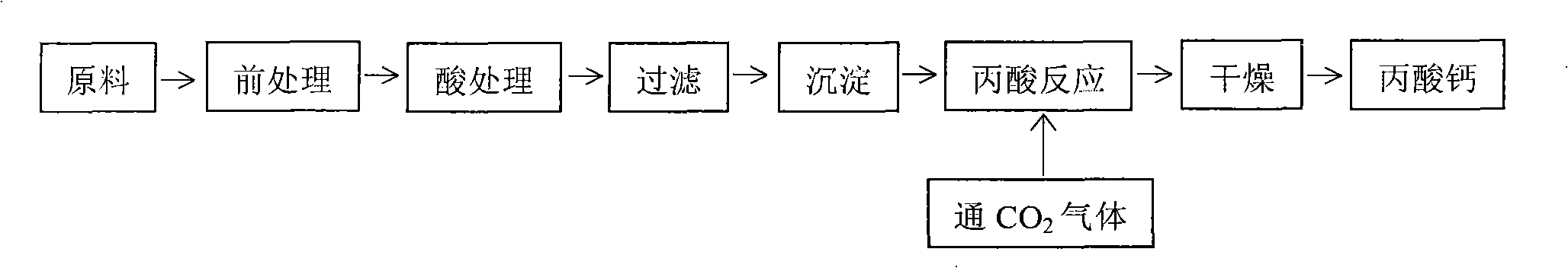

Method used

Image

Examples

Embodiment 1

[0025] Prepare calcium propionate as follows:

[0026] (1) Wash the Pinctada martensii shells after bead opening 3 times with tap water to remove the impurities adhered to the shell surface; add 0.20mol / L hydrochloric acid and stir and soak for 2 minutes, then rinse with clear water to remove the pigment on the shell surface layer and a small amount of soluble organic matter; air-dried, dried at 100°C for 1 hour, then crushed the dried shells, and passed through an 80-mesh sieve to obtain shell powder.

[0027] (2) Take 1000 grams of shell powder, prepare 3mol / L hydrochloric acid, add shell powder to the acid solution at a ratio of 1:15, dissolve at 30°C for 4 hours, and stir occasionally to obtain Mixture.

[0028] (3) The mixed solution after the acid treatment is centrifuged, the supernatant is taken out, and 1.0mol / L sodium carbonate solution is slowly added, wherein the volume ratio of the supernatant solution and the sodium carbonate solution is 9: 4, while constantly s...

Embodiment 2

[0032] Prepare calcium propionate as follows:

[0033] (1) Wash the pearl oyster shells after opening the pearls with tap water 3 times to remove the impurities adhered to the shell surface; add 0.50mol / L hydrochloric acid and stir and soak for 5 minutes, then rinse with clear water to remove the pigment on the shell surface layer and a small amount of soluble organic matter; air-dried, dried at 110° C. for 1.5 hours, then crushed the dried shells, and passed through a 120-mesh sieve to obtain shell powder.

[0034] (2) Take 500 grams of shell powder, prepare 5mol / L hydrochloric acid, add shell powder to the acid solution at a ratio of 1:20, dissolve at 40°C for 2 hours, and stir occasionally to obtain Mixture.

[0035] (3) Centrifuge the mixed solution after the acid treatment, extract the supernatant, slowly add 1.0mol / L sodium carbonate solution, wherein the volume ratio of the supernatant to the sodium carbonate solution is 9:5, and keep stirring , after sufficient preci...

Embodiment 3

[0039] Prepare calcium propionate as follows:

[0040] (1) Wash the Pinctada martensii shells after bead opening 3 times with tap water to remove the impurities adhered to the shell surface; add 0.30mol / L hydrochloric acid and stir and soak for 3 minutes, then rinse with clear water to remove the pigment on the shell surface layer and a small amount of soluble organic matter; air-dried, dried at 105° C. for 2.0 hours, then crushed the dried shells, and passed through a 100-mesh sieve to obtain shell powder.

[0041] (2) Take 500 grams of shell powder, prepare 4mol / L hydrochloric acid, add shell powder to the acid solution at a ratio of 1:25, dissolve at 35°C for 3 hours, and stir occasionally to obtain Mixture.

[0042](3) Centrifuge the mixed solution after the acid treatment, extract the supernatant, slowly add 1.0mol / L sodium carbonate solution, wherein the volume ratio of the supernatant to the sodium carbonate solution is 9:6, and keep stirring , after sufficient precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com