Method for growing high quality nano-diamond membrane with low cost

A nano-diamond, high-quality technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of poor reusability, high preparation cost and limited life of hot wire, and achieve unique field emission advantages , The effect of low preparation cost and large excitation current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

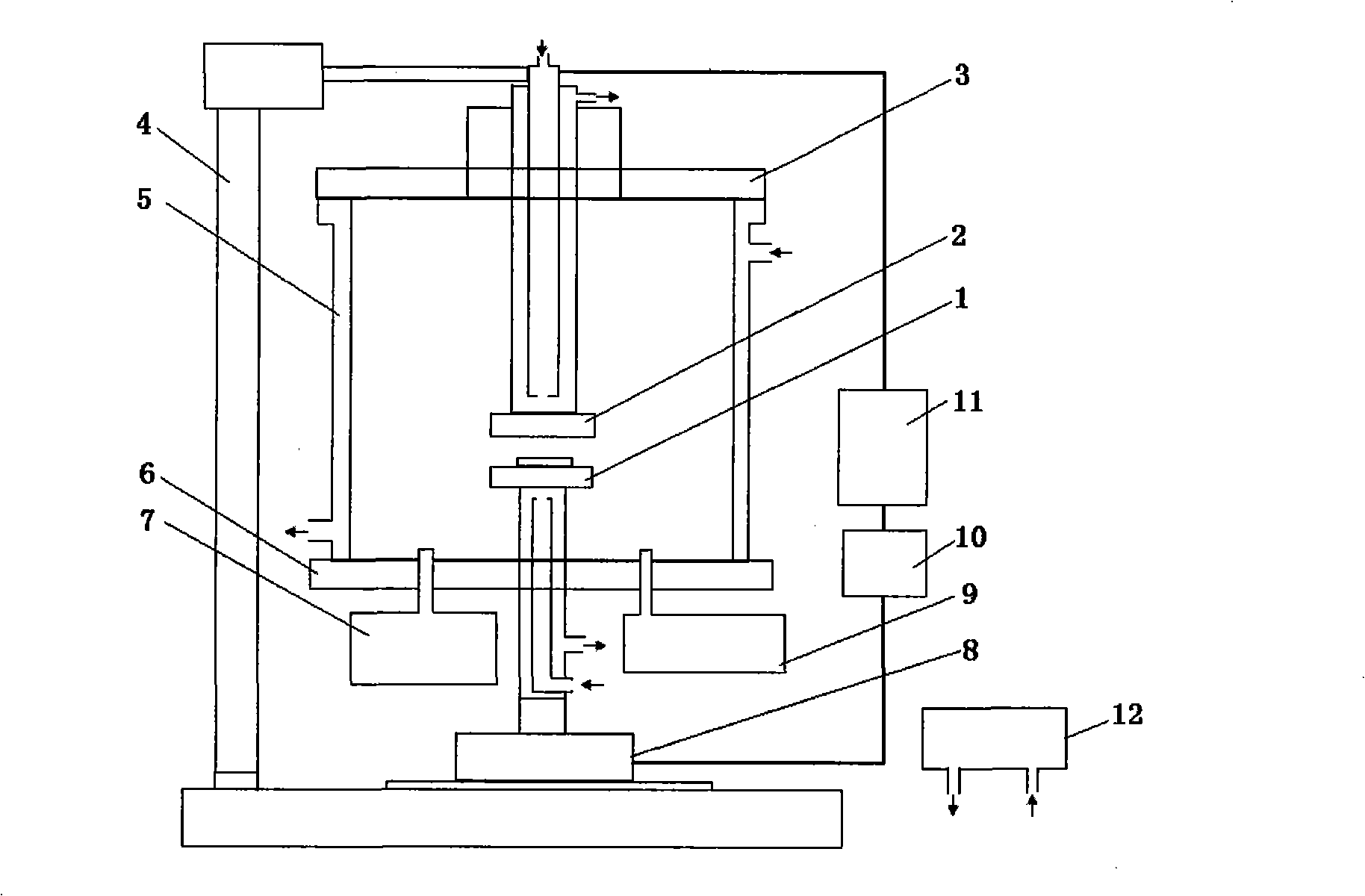

[0014] Specific implementation mode one: as figure 1 As shown, the present embodiment prepares the nano-diamond film in the equipment for growing high-quality nano-diamond film at low cost. System 12. The cathode 2 is fixed at the center position of the end cap 3, and the cathode 2 and the end cap 3 can be raised and lowered under the traction of the end cap lifting device 4, so that the growth chamber 5 is opened or closed; the anode 1 is raised and lowered under the traction of the anode lifting device 8; The air intake device 7 and the vacuum device 9 communicate with the growth chamber at the lower end cover 6 of the growth chamber 5; through the adjustment of the voltage regulator 10, the voltage output from the power supply 11 to the cathode 2 and the anode 1 is changed; the water cooling system 12 is respectively It communicates with the wall of the cathode 2, the anode 1 and the growth chamber 5, and the water cooling channels communicate with each other. The distanc...

specific Embodiment approach 2

[0024] Specific implementation mode 2: In this implementation mode, a low-cost and high-quality nano-diamond film is prepared according to the following method:

[0025] a. Ultrasonic grinding of the Si sheet with diamond powder for 1 h, ultrasonic cleaning with ethanol for 1 h, drying and putting it on the anode platform in the growth chamber. After the descending end cap is sealed, the growth chamber is evacuated to 10 -1 Pa, close the main valve for vacuuming, open the flow meter and fill it with H with a flow rate of 200-300 sccm 2 . Adjust the position of the anode close to the cathode by about 20mm, and wait for the air pressure in the growth chamber to rise to 0.8×10 3 Pa, add voltage, adjust the working voltage, so that the electrode can reach a stable glow discharge state.

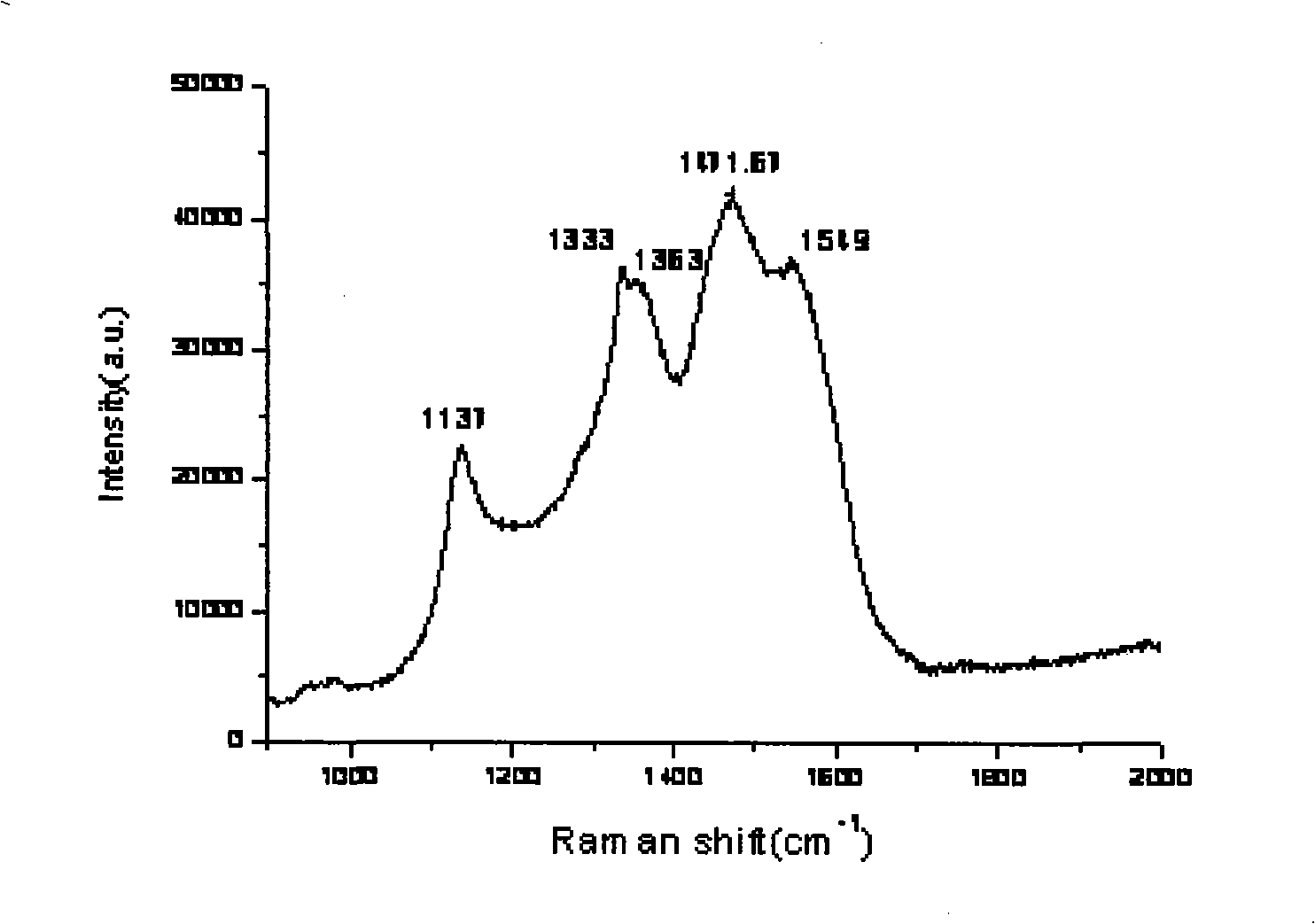

[0026] b. After the discharge is stable, charge H with a flow rate of 200 sccm 2 , CH at 10 sccm 4 , keep the growth chamber pressure at 1.2×10 4 Pa, Si sheet temperature 850°C, excitation v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com