Method for removing sodium oxalate from industrial sodium aluminate solution

A technology for industrial sodium aluminate and sodium oxalate, applied in the field of impurity sodium oxalate, can solve the problems of calcium oxalate crystal seed being easy to lose activity, unfavorable sodium oxalate crystallization precipitation, sodium oxalate easy to lose activity, etc., achieving low cost, pretreatment Simple process, easy to separate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

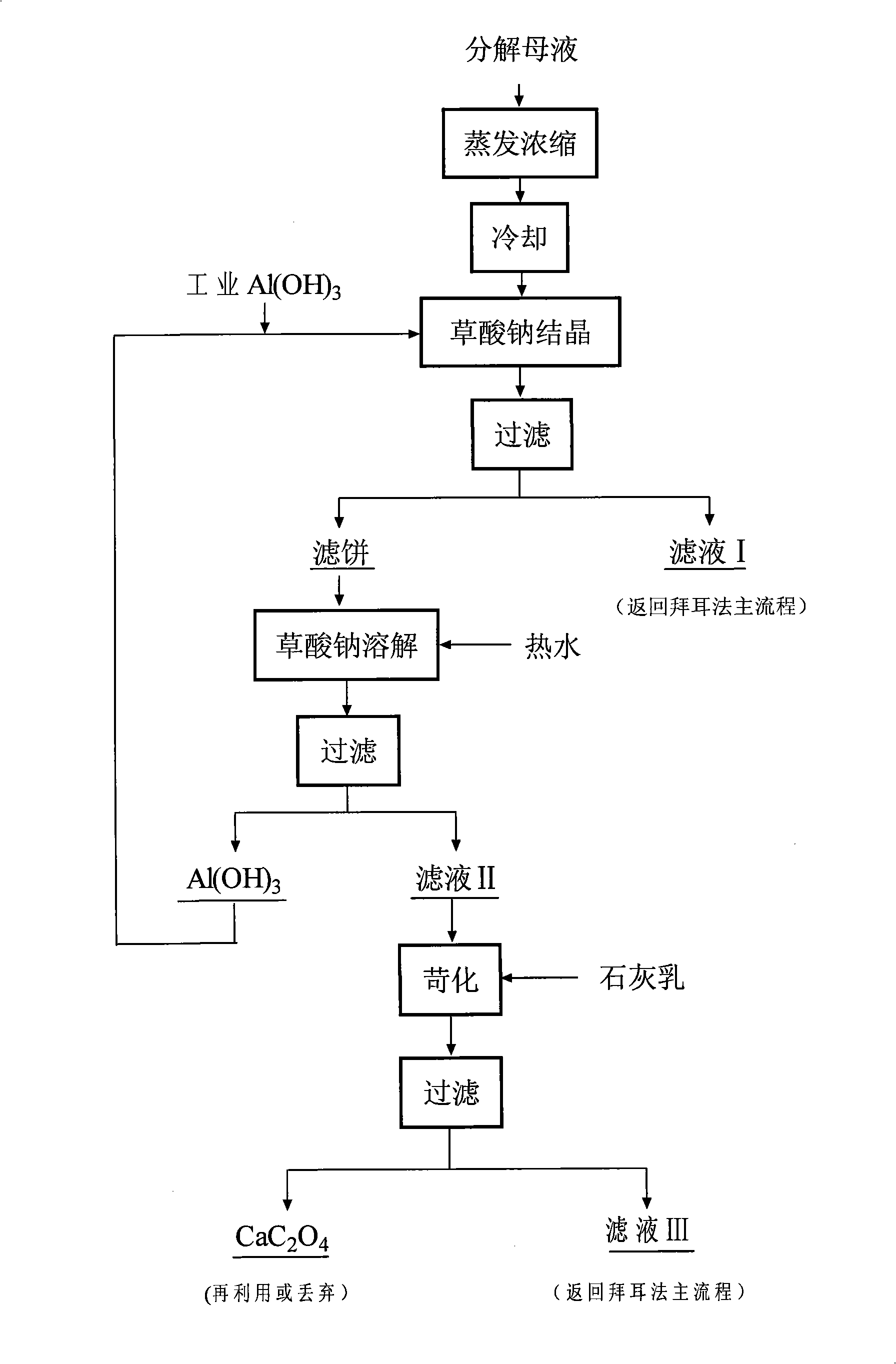

Image

Examples

Embodiment 1

[0046] The caustic alkali concentration of the decomposed mother liquor in an alumina factory is 162g / L. When the concentration of caustic alkali is 243g / L after evaporation and concentration, 20g / L aluminum hydroxide seed crystals are added at a constant temperature of 40°C, and the rotation speed is 100r / Stir for 12 hours under the condition of min, stop stirring, filter the slurry with a vacuum filter, return the filtrate to the main production process of the Bayer process, wash the filter cake with hot water at 60°C, and filter with a vacuum filter. Aluminum, as the next batch of sodium aluminate solution to crystallize and separate out the sodium oxalate crystal seed, the filtrate mainly contains sodium oxalate, causticizing and recovering caustic. After the above treatment, the content of sodium oxalate in the sodium aluminate solution returned to the main production process of the Bayer process decreased by 0.69g / L.

Embodiment 2

[0048] The caustic alkali concentration of the decomposed mother liquor in an alumina factory is 162g / L. When the concentration of caustic alkali is 180g / L after evaporation and concentration, 10g / L aluminum hydroxide seed crystals are added at a constant temperature of 20°C, and the rotation speed is 100r / Stir for 24 hours under the condition of min, stop stirring, filter the slurry with a vacuum filter, return the filtrate to the main production process of the Bayer process, wash the filter cake with hot water at 60°C, and filter with a vacuum filter. Aluminum, as the next batch of sodium aluminate solution to crystallize and separate out the sodium oxalate crystal seed, the filtrate mainly contains sodium oxalate, causticizing and recovering caustic. After the above treatment, the content of sodium oxalate in the sodium aluminate solution returned to the main production process of the Bayer method decreased by 0.67g / L.

Embodiment 3

[0050] The caustic alkali concentration of the decomposed mother liquor in an alumina plant is 162g / L. When the concentration of caustic alkali is 243g / L after evaporation and concentration, 20g / L aluminum hydroxide seed crystals are added at a constant temperature of 35°C, and the rotation speed is 100r / Stir for 48 hours under the condition of min, stop stirring, filter the slurry with a vacuum filter, return the filtrate to the main production process of the Bayer process, wash the filter cake with hot water at 60°C, and filter with a vacuum filter. Aluminum, as the next batch of sodium aluminate solution to crystallize and separate out the sodium oxalate crystal seed, the filtrate mainly contains sodium oxalate, causticizing and recovering caustic. After the above treatment, the content of sodium oxalate in the sodium aluminate solution returned to the main production process of the Bayer method decreased by 0.80g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com