Surface passivation treating liquid for organic-inorganic composite metals

A technology of composite metal surface and passivation treatment, applied in the field of metal material surface treatment, can solve problems such as performance gap, and achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The main components of the organic and inorganic composite passivation solution in which manganate is the main inorganic salt are:

[0022] Potassium permanganate 6g

[0023] Dipotassium hydrogen phosphate 20g

[0024] Thiourea 5g

[0025] Phosphoric acid 5g

[0026] Waterborne Polyurethane 150g

[0027] Deionized water 750g

[0028] Curing agent (aliphatic polyisocyanate) 3g

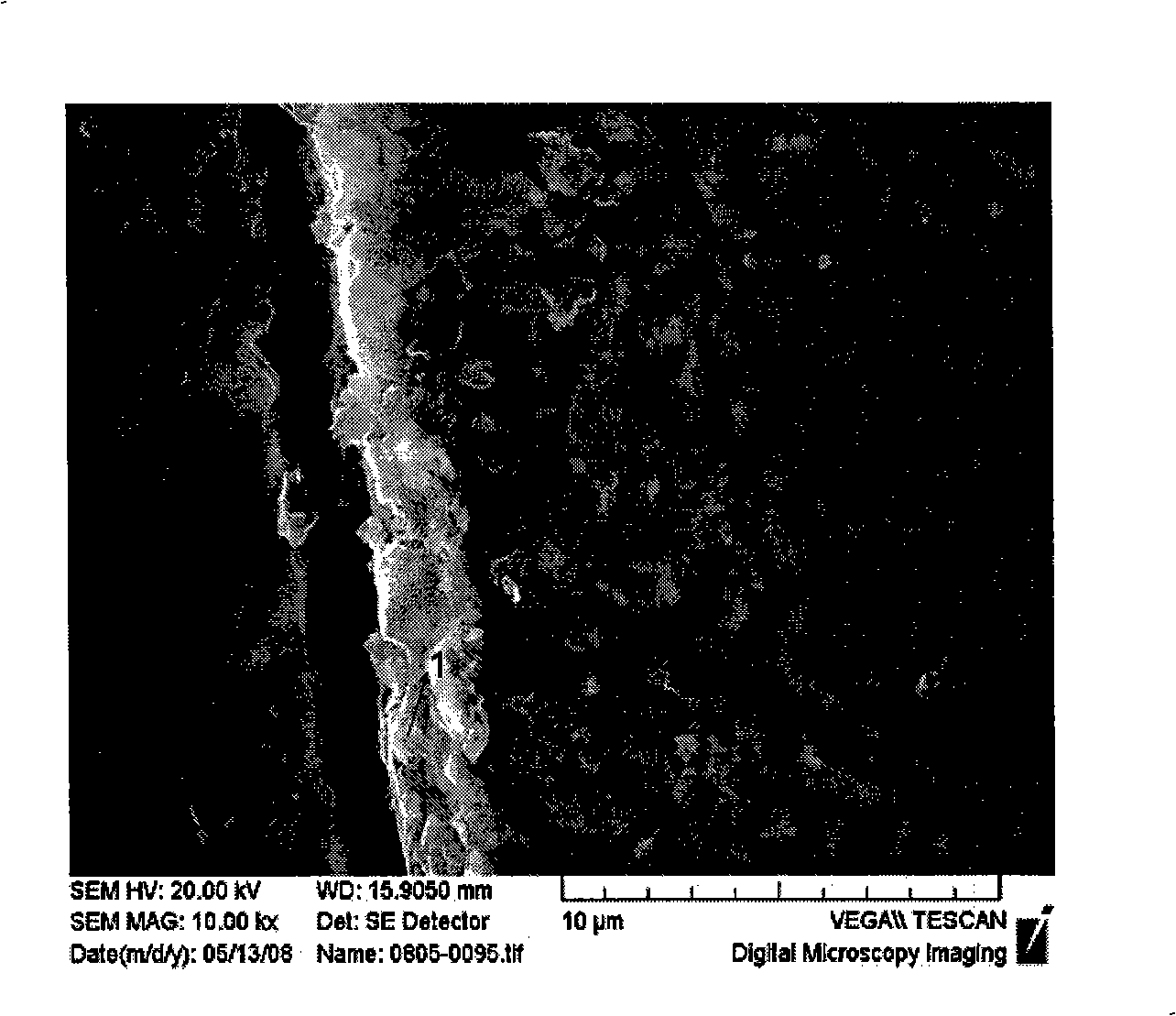

[0029] 3 is a cross-sectional scanning electron micrograph of Example 1. It can be seen from Figure 3 that the thickness of the passivation film is about 2 μm.

Embodiment 2

[0031] The main components of the organic and inorganic composite passivation solution with titanium salt as the main inorganic salt are:

[0032] Titanyl Sulfate 5g

[0034] Fluorosilicate 30g

[0035] Thiourea 4g

[0036] Phosphoric acid 12g

[0037] Waterborne Polyurethane 150g

[0038] Deionized water 760g

[0039] Curing agent (aliphatic polyisocyanate) 3g

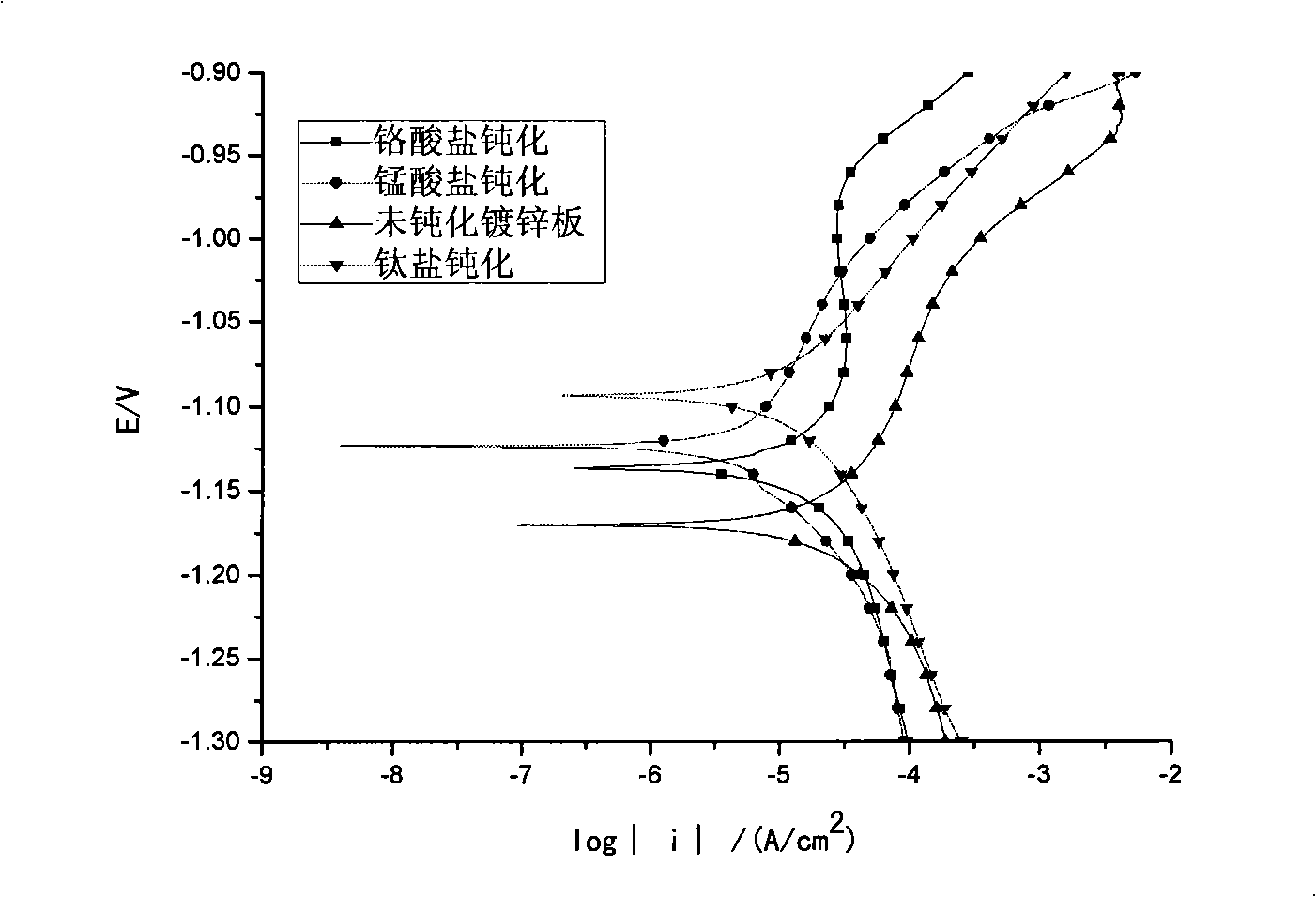

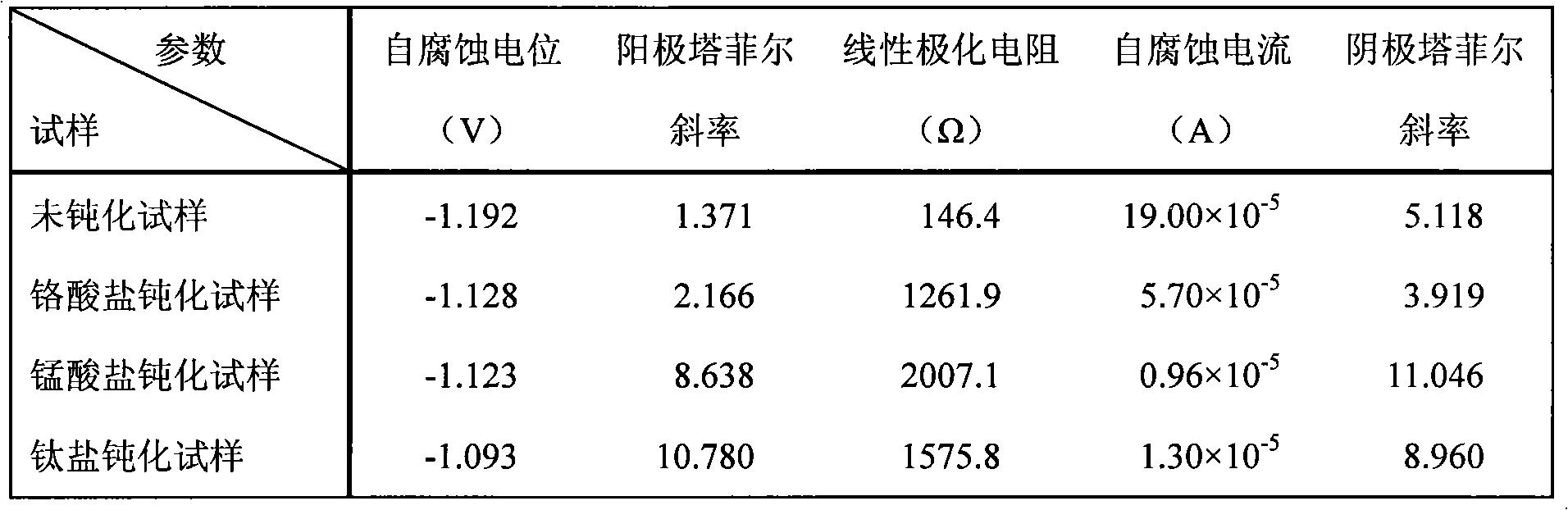

[0040] In order to have a more intuitive understanding of the passivation effect, a comparative experiment was carried out to compare with the galvanized sheet without passivation treatment and the galvanized sheet treated with low chromate passivation.

[0041] 1. The main components of low chromate passivation solution are:

[0043] Sulfuric acid 0.3g

[0044] Nitric acid 3g

[0045] Glacial acetic acid 5g

[0046] Deionized water 950g

[0047] Treatment conditions: pH value is 2, at room temperature Coating method: soak in passivation solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com