Method for measuring trace amount calcium in steel

A trace and microwave digestion technology, used in the field of trace calcium determination in steel, can solve the problems of high blank value, large amount of reagents, unstable measurement results, etc., to achieve accurate measurement results, reduce measurement blanks, and good consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1 using the instrument

[0028] IRIS Advantage full-spectrum direct-reading plasma emission spectrometer (Thermo Electric Company of the United States); microwave digestion system, MILESTONE ETHOS TC high-pressure microwave digestion furnace (Italy);

[0029] 2. Using Reagents

[0030] All reagents used were of superior grade;

[0031] The 1.000mg / mL Ca standard working solution was prepared with calcium carbonate (99.99%). During the measurement, dilute with aqua regia step by step to form a standard working solution with a calcium concentration of 0.0ug / mL, 0.1ug / Ml, 0.2ug / mL, 0.5ug / mL, and 1.0ug / mL.

[0032] 3. Calibration curve drawing

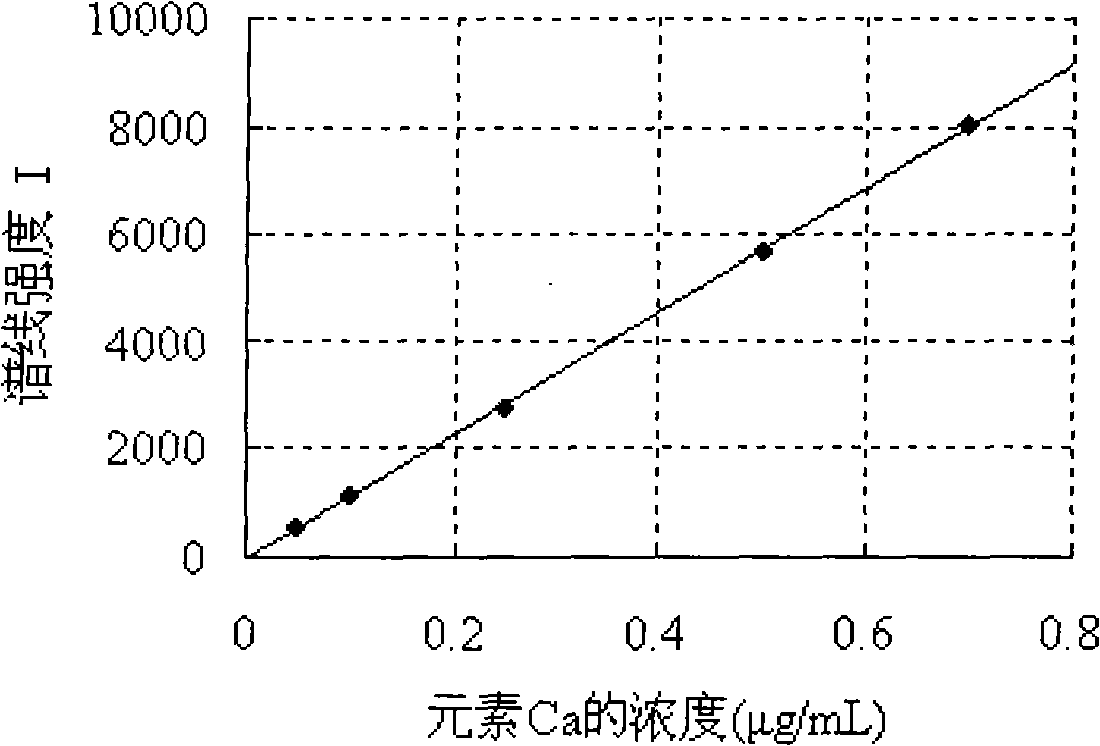

[0033] Use the standard working solution of calcium, measure under the working conditions of the instrument in Table 1, and the computer automatically draws the calibration curve, see figure 1 .

[0034] Table 1 Working conditions of the spectrometer

[0035]

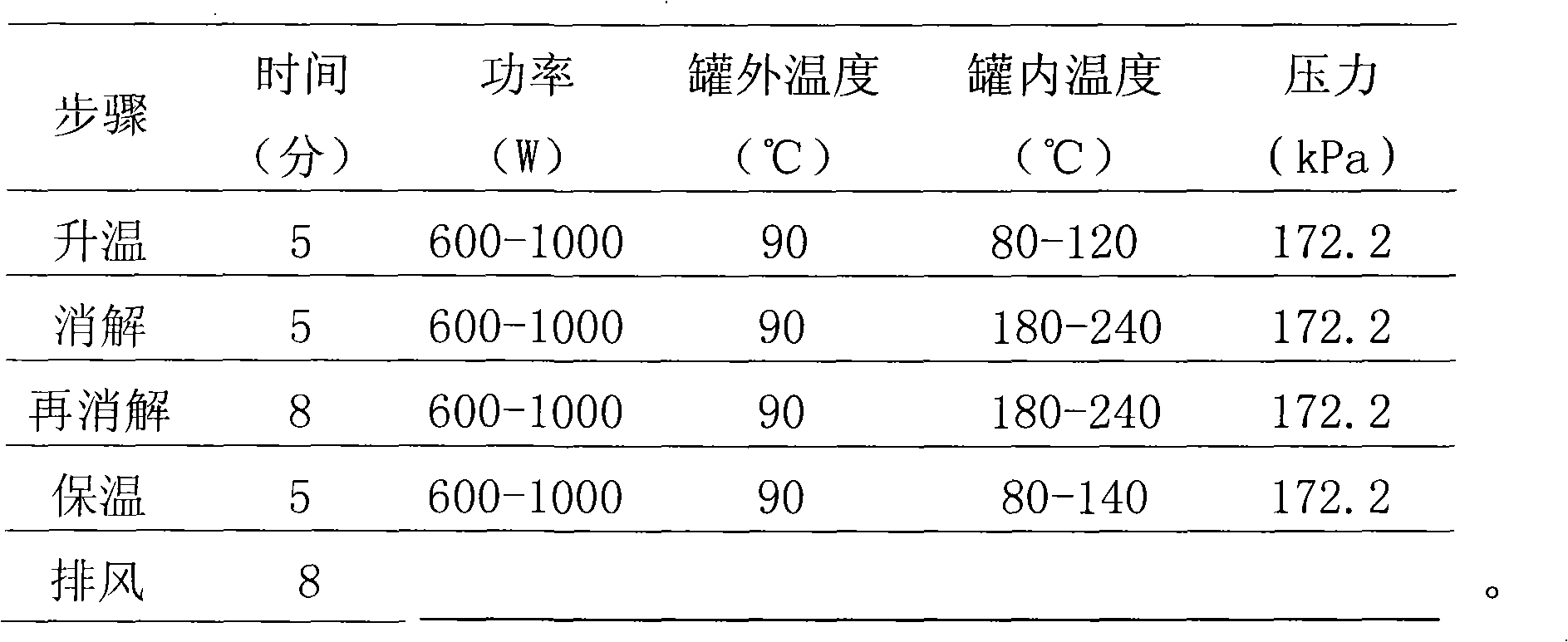

[0036] Table 2 Conditions of microwave digestion

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com