Impulsing power source for spark pinhole processing

A technology of pulse power supply and hole processing, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., and can solve the problems of low power utilization, easy arcing, and large loss of tubular electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

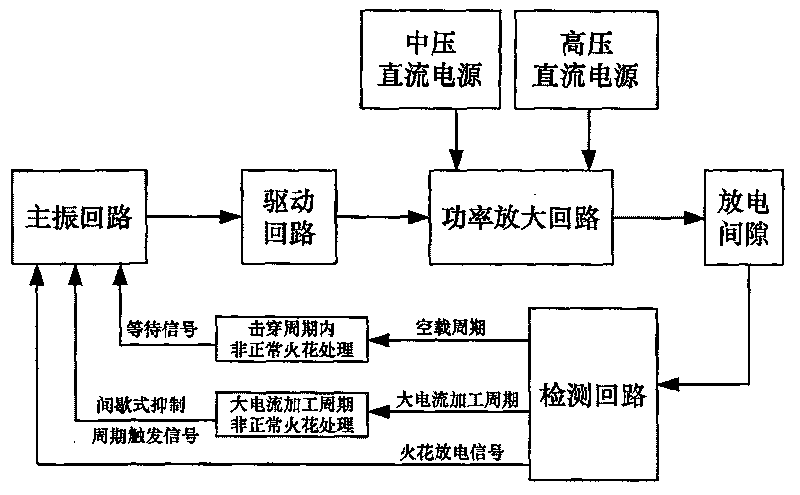

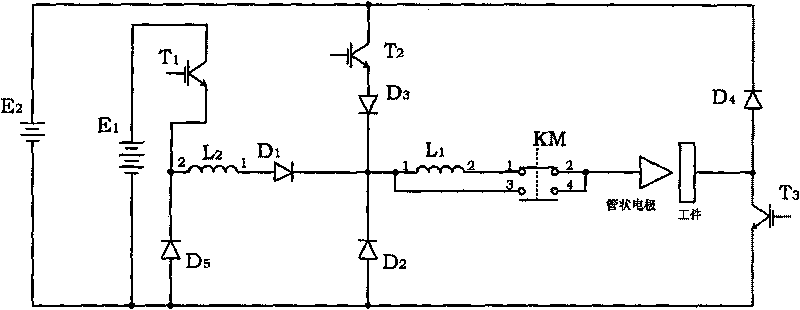

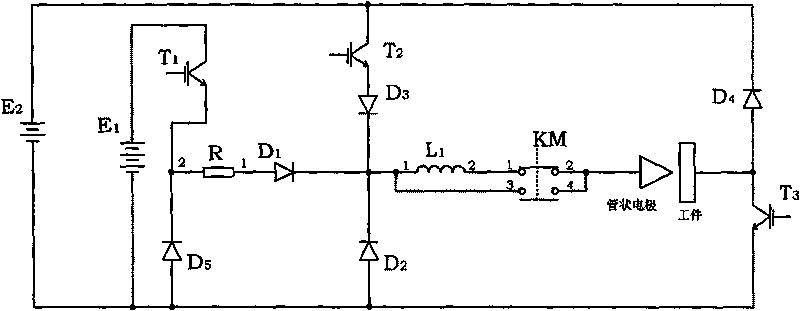

[0022] The present invention is a kind of pulse power supply suitable for electric spark high-speed small hole machining machine tool for machining small holes. Periodic abnormal spark processing module, medium-voltage DC power supply, high-voltage DC power supply and power amplification circuit (see figure 1 shown). The abnormal spark processing module in the breakdown cycle and the abnormal spark processing module in the high current processing cycle are arranged between the main vibration circuit and the detection circuit. In the present invention, the main vibration circuit, the drive circuit and the detection circuit are the conventional circuit structures of the existing electric discharge high-speed small hole machining machine tool.

[0023] The detection circuit is used for real-time online detection of the three discharge states of no-load, short ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com