Solid electrolytic capacitor and method of processing the same

A technology of solid electrolysis and processing method, applied in the field of capacitors, can solve the problems of poor stability, unstable structure and low yield of electrolytic capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

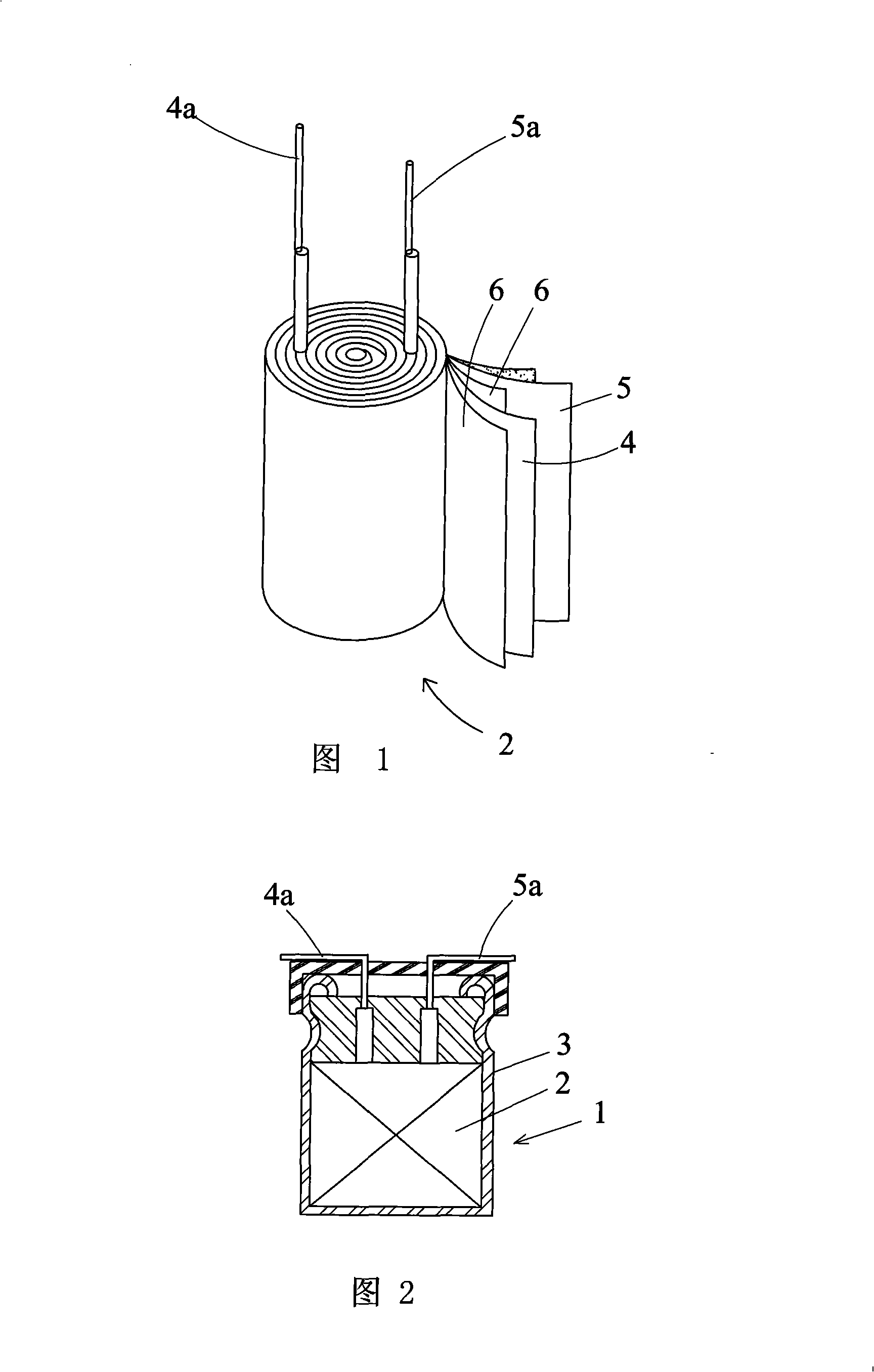

[0017] See Fig. 1, Fig. 2, the present invention comprises anode film 4, anode 4a, cathode film 5, cathode 5a and form conductive polymer electrolyte layer between anode film 4 and cathode film 5, and the surface of anode film 4 is covered with oxide medium The electric surface layer and the carrier of the conductive polymer electrolyte layer are the isolation layer 6; the base material of the isolation layer 6 contains polyacrylonitrile-based carbon fibers, pitch-based carbon fibers or rayon-based carbon fibers. The base material of the anode film 4 is aluminum foil;

[0018] Describe processing method of the present invention below in conjunction with accompanying drawing:

[0019] The etched conductive metal foil is used as the anode film 4, and its surface is anodized to form an oxidized dielectric surface layer, and the anode film 4 is heat-treated at an appropriate temperature (such as 280°C) to stabilize the properties of the oxidized dielectric surface layer , the ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com