Functional nano Ti2O/Cu2O heterophase Fenton thin film and preparation method as well as use

A functional nano and heterogeneous technology, applied in chemical instruments and methods, anti-fouling/underwater coatings, chemical/physical processes, etc., can solve problems such as easy recombination, accelerated oxidation, and low carrier transport efficiency, and achieve chemical The effect of good stability and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of TiO by Electrochemical Method 2 / Cu 2 O nanocomposites to finally obtain functional nano-TiO 2 / Cu 2 The process of O heterogeneous Fenton composite thin film material:

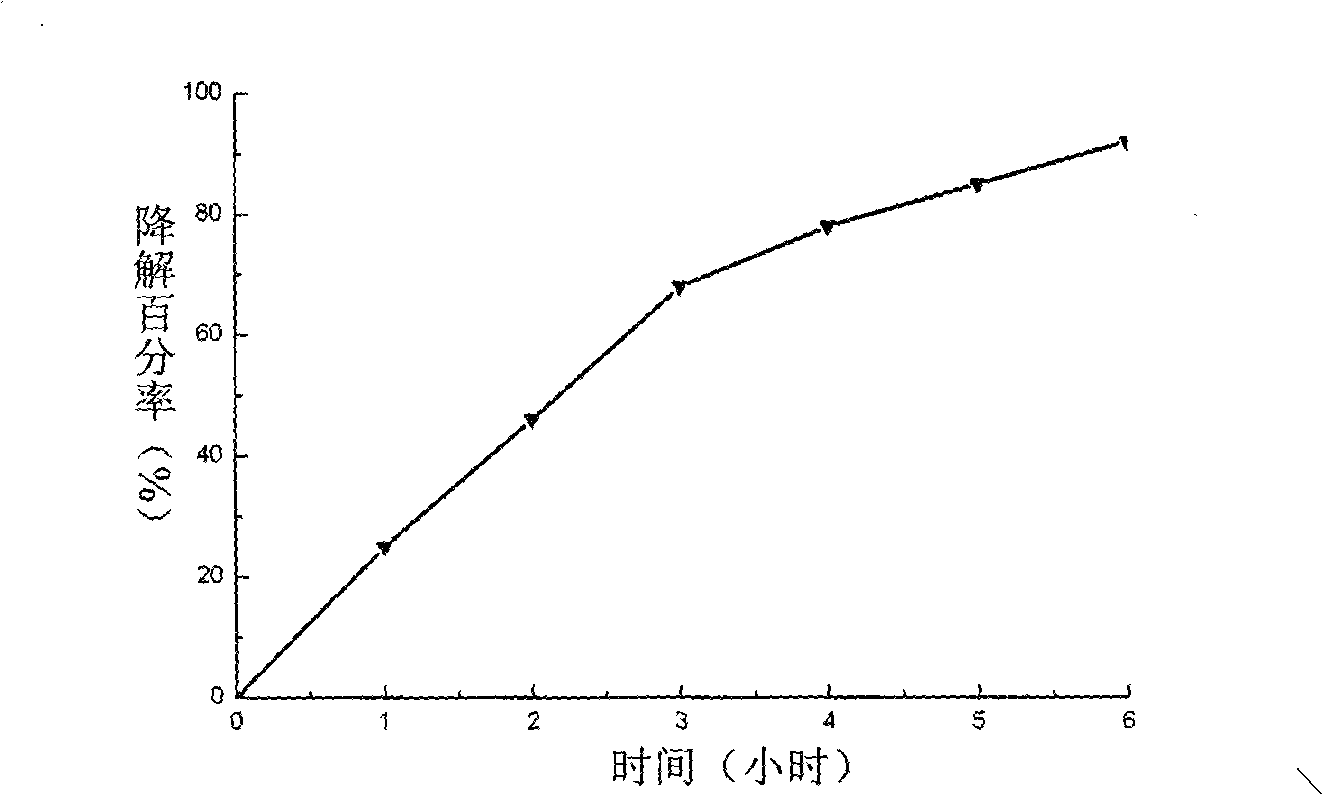

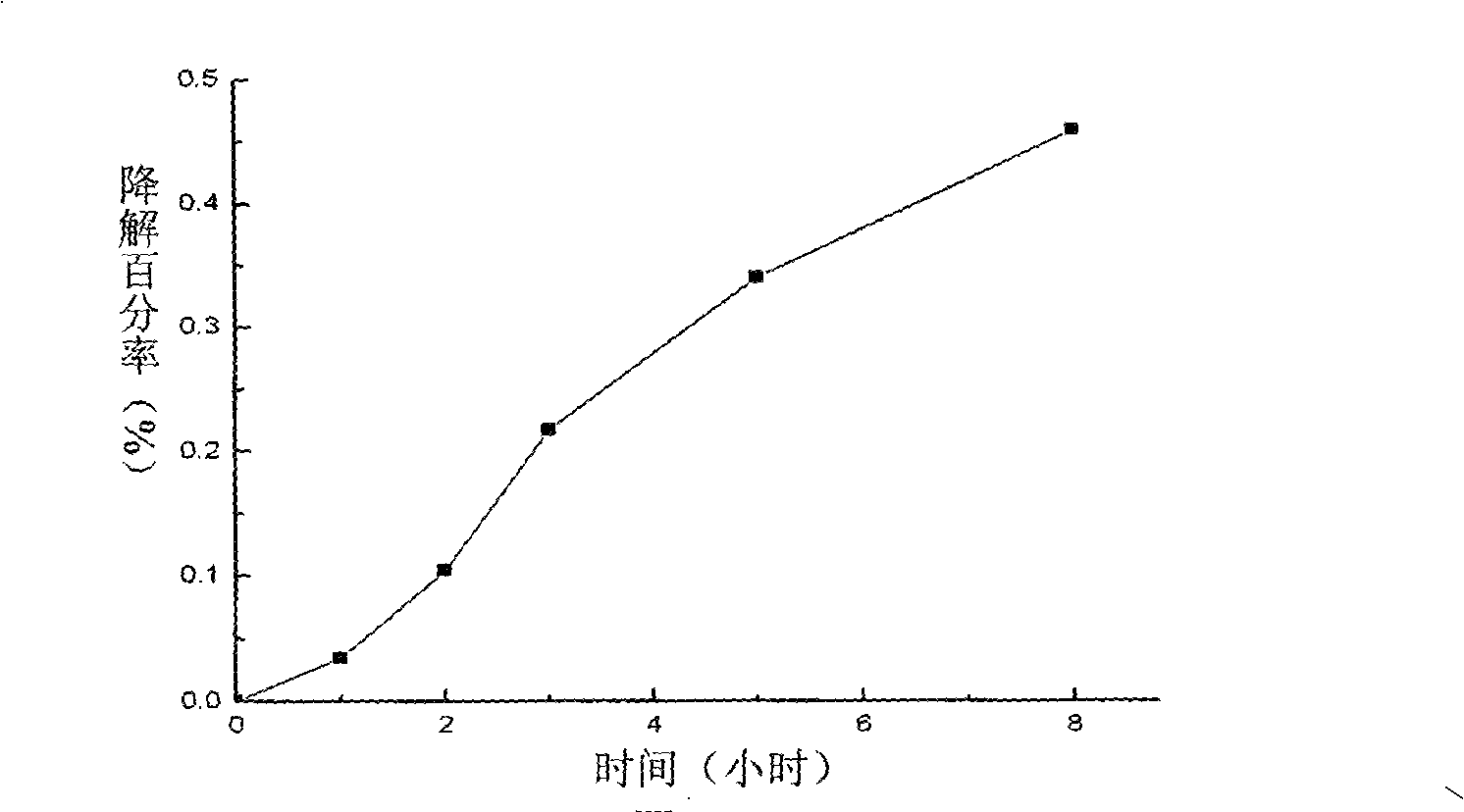

[0039] Add 2g of mechanically ground nano-TiO to the cathode cell before electrolysis 2 (P25, TiO with 80% anatase and 20% rutile 2 , Dessuga Co) The electrolyte is 0.1 mol / L NaOH alkaline solution, titanium is used as the cathode; 1M NaCl salt solution is added to the anode cell, the copper plate is used as the anode, and the copper is reduced to Cu by electrolysis 2 O. During electrolysis, the current is controlled to be 0.5A, the temperature is about 80°C, and the reaction time is 20 minutes. Stirring should be continued during the electrolysis process. The electrolysis product was separated by centrifugation, washed three times with ethanol and distilled water, and dried in vacuum at 60°C to obtain TiO 2 / Cu 2 O (mass ratio of 1:1) nanocomposites. The prepared 1g of the abov...

Embodiment 2

[0053] Preparation of TiO by Chemical Deposition 2 / Cu 2 O nanocomposites to finally obtain nano-TiO 2 / Cu 2 The process of O heterogeneous Fenton composite thin film material:

[0054] In 200ml of diethylene glycol solvent, add 4g of mechanically ground nano-TiO 2 (P25, TiO with 80% anatase and 20% rutile 2 , Dessuga Co) and 0.1M copper acetate, and stirred to make TiO 2 Disperse evenly in the system. Raise the temperature to about 180°C, and the reaction time is 3 hours, and the stirring should be continued during the reaction. After the reaction was completed, the product was centrifuged and washed three times with ethanol, and then vacuum-dried at 60°C to obtain TiO 2 / Cu 2 O nanocomposites. The 2g above-mentioned composite material that makes and 15ml lithium water glass (Li 2 SiO 3 , containing 20% SiO 2 , New Material Factory of Central China Normal University) mixed and uniformly coated on the surface of glass fiber cloth (300mm×300mm) to make TiO 2 / Cu ...

Embodiment 3

[0057] Preparation of TiO by hydrothermal (or solvothermal) method 2 / Cu 2 O nanocomposites to finally obtain nano-TiO 2 / Cu 2 The process of O heterogeneous Fenton composite thin film material:

[0058] Before the reaction, add 3 g of mechanically ground nano-TiO in 80 ml of ethanol-water mixed solvent (the volume ratio of ethanol to water is 1:3). 2 (P25, TiO with 80% anatase and 20% rutile 2 , Dessuga Co) and 0.05M copper sulfate, adjust the pH value to 7-9, ultrasonically make TiO 2 Disperse evenly in the system. Transfer the mixed solution to a hydrothermal kettle, put it into a muffle furnace, raise the temperature to 180-200° C., and the reaction time is 18 hours. After the reaction was completed, the product was centrifuged, washed three times with ethanol and distilled water, and dried in vacuum at 60°C to obtain TiO 2 / Cu 2 O nanocomposites. The prepared 3g of the above TiO 2 / Cu 2 O nanocomposites with 15ml lithium water glass (Li 2 SiO 3 , containing 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com