Method for preparing plastic wood compound material/rigid foam composite and light weight type wall plate

A wood-plastic composite material and lightweight wallboard technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of low processing efficiency and difficulty in ensuring the strength of foamed materials, and achieve light weight and good mechanical properties. performance, ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

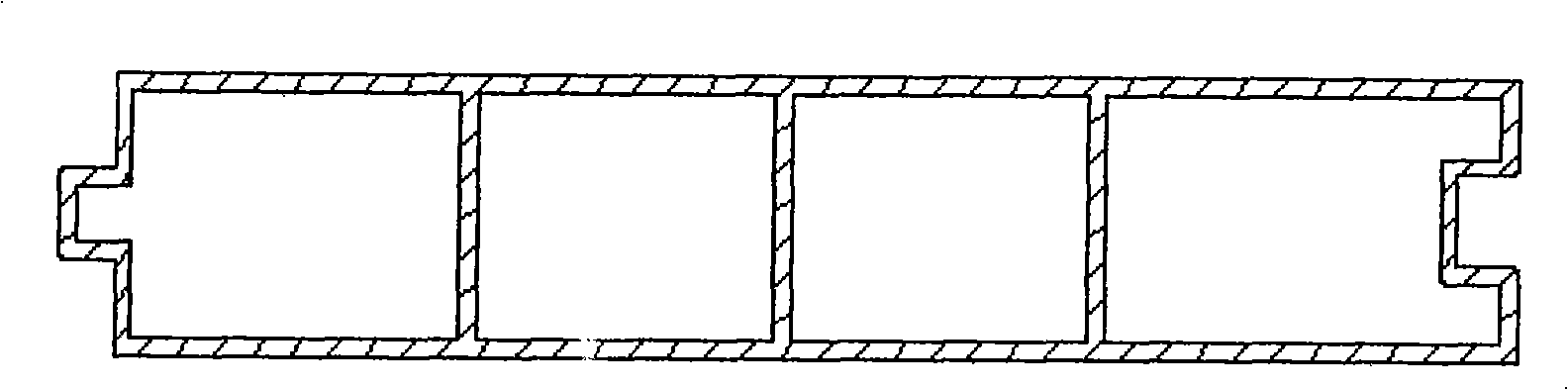

Image

Examples

Embodiment 1

[0020] Example 1: Using 60 mesh hardwood powder 55wt%, high-density polyethylene (HDPE) 35wt%, polyolefin graft compatibilizer 4.0wt%, lubricant polyethylene wax 1.0wt%, crosslinking agent DCP (peroxide Diisopropylbenzene) 0.3wt%, dispersant stearic acid 0.5wt%, PKB-215 composite antioxidant 0.2wt%, inorganic filler calcium carbonate 5.0wt%, and processed according to the following steps,

[0021] a. The wood flour is added to the high-speed mixer, heated and stirred to 110°C to remove the water in the wood flour, and at the same time, the dispersant and inorganic fillers are added to make a dried wood flour raw material;

[0022] b. Continue to add high-density polyethylene, compatibilizer, lubricant, cross-linking agent, and antioxidant to the wood flour raw materials and mix them at high speed to 120°C, and mix the materials thoroughly to make composite raw materials;

[0023] c. The mixed composite raw materials are added to the SJZ-80 / 156 conical twin-screw extruder for blend...

Embodiment 2

[0026] Example 2: The processing steps are the same as in Example 1. The microencapsulated red phosphorus flame retardant is added to the pellet formulation, and the distribution ratio of each component is: 60 mesh wood powder 55wt%, high-density polyethylene (HDPE) 30wt% , Polyolefin grafting compatibilizer 4.0wt%, lubricant polyethylene wax 1.0wt%, crosslinking agent DCP (dicumyl peroxide) 0.3wt%, dispersant stearic acid 0.5wt%, composite PKB-215 Antioxidant 0.2wt%, inorganic filler calcium carbonate 4.0wt%, microencapsulated red phosphorus environmentally friendly flame retardant 5.0wt%. Using the components of this formula and the processing equipment and technology of Example 1, a flame-retardant composite lightweight wallboard was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com