Micro-cavity optical amplifier structure of 980 nanometer semiconductor with high gain and low noise

A 980nm, optical amplifier technology, applied in semiconductor lasers, the structure of optical resonators, lasers, etc., can solve the problems of large number of longitudinal modes, suppression of signal gain, and small interval of longitudinal modes, and achieve the effect of low noise and high gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

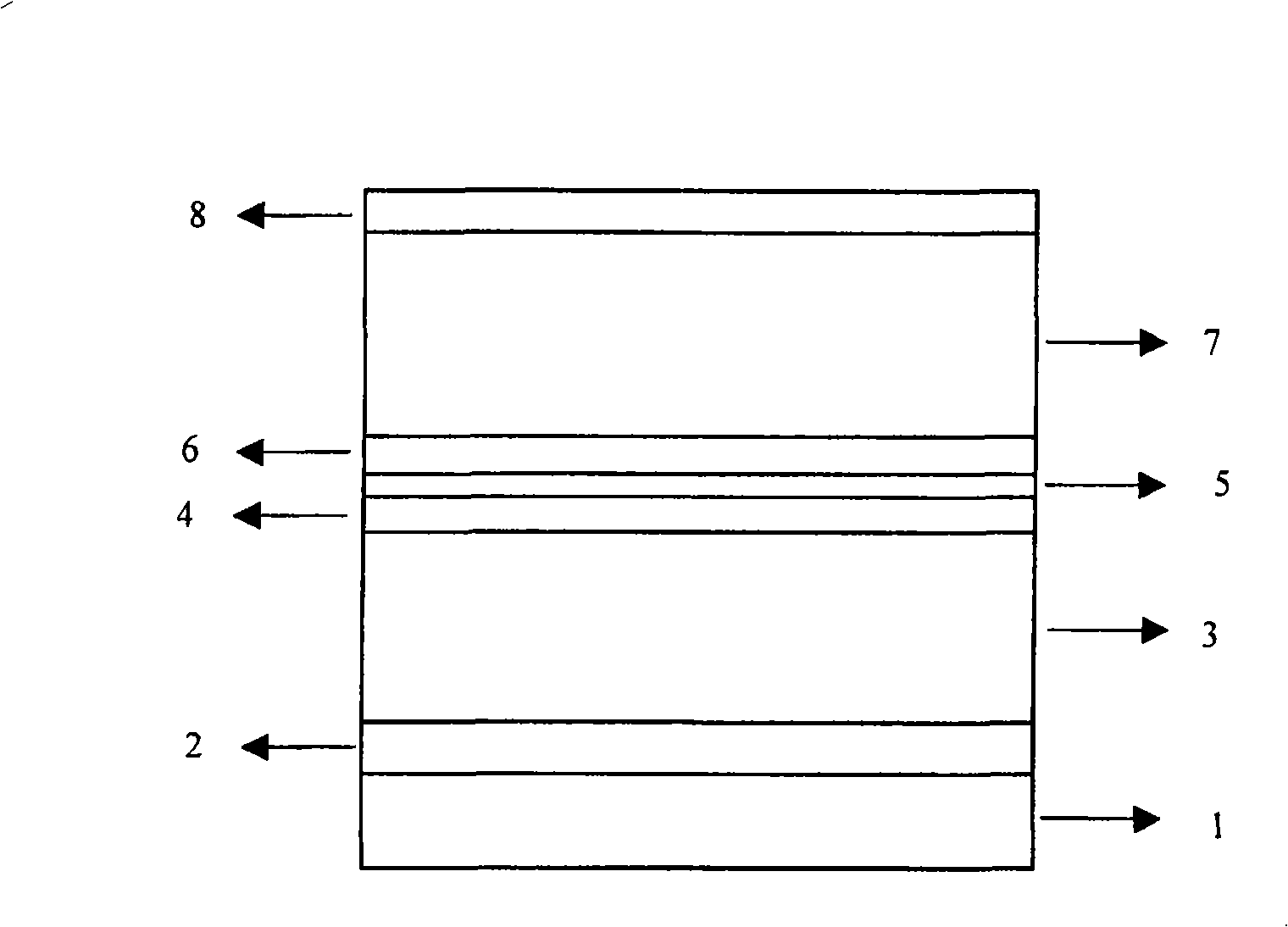

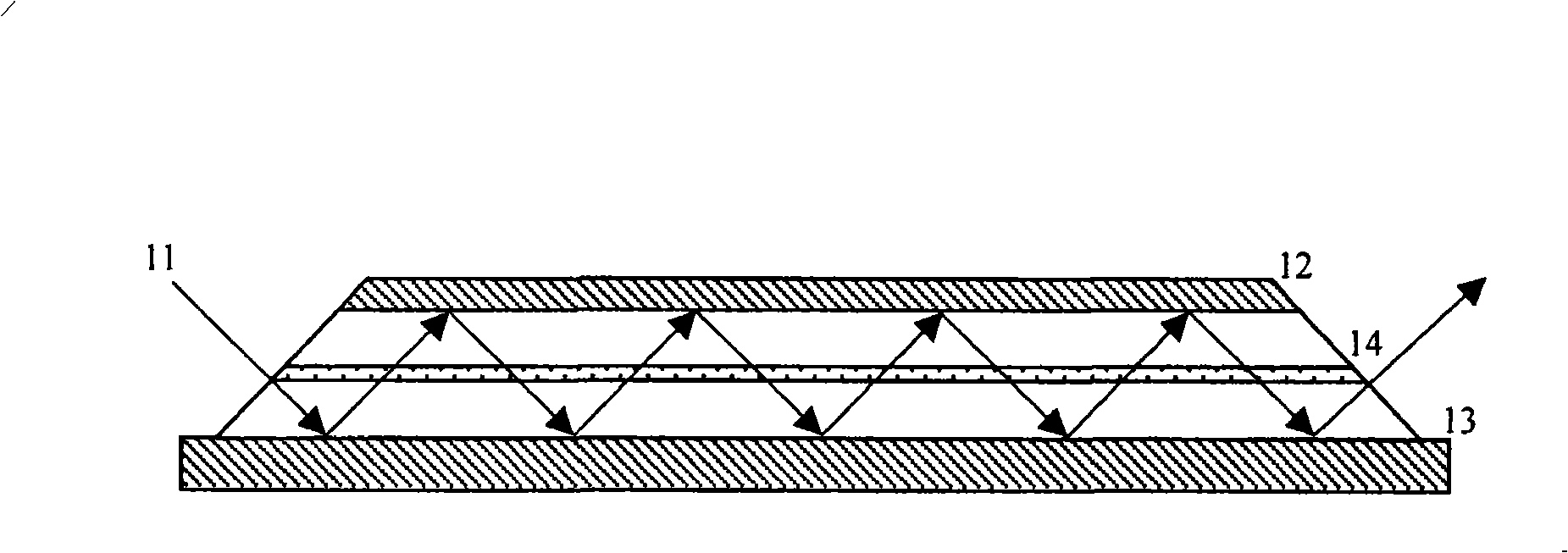

[0028] Combine below figure 1 and figure 2 Describe in detail the structure and working principle of a high-gain, low-noise 980nm semiconductor microcavity optical amplifier according to a specific embodiment of the present invention.

[0029] see figure 1 , a high-gain, low-noise 980nm semiconductor microcavity optical amplifier structure of the present invention, is characterized in that, comprises:

[0030] A substrate 1, the substrate 1 is used to make different epitaxial material layers required for growing optical amplifiers, and the substrate 1 is N-gallium arsenide material;

[0031] A buffer layer 2, the buffer layer 2 is fabricated on the substrate 1, and the buffer layer 2 is N-gallium arsenide material;

[0032] A lower Bragg reflector 3, the lower Bragg reflector 3 is made on the buffer layer 2, and the lower Bragg reflector 3 is made up of 19 cycles, N-gallium arsenide and N-aluminum arsenide layers; each cycle Both gallium arsenide and aluminum arsenide lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com