Aluminum-silicon-titanium composite oxide carrier and load type catalytic hydro-dearomatization catalyst

A composite oxide, aluminum silicon titanium technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc., can solve the problem of poor stability, unsatisfactory effect, and unsatisfactory Catalyst long cycle life requirements and other issues, to achieve the effect of simple synthesis conditions and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh a certain amount of pseudo-boehmite, make a slurry with absolute ethanol, the mass of absolute ethanol used is 1.0 to 1.3 times the mass of pseudo-boehmite, and then slowly add concentrated Nitric acid until the precipitate disappears and a uniform slurry is formed to obtain an aluminum sol.

[0036] Dissolve deionized water and nitric acid in absolute ethanol in sequence, the molar ratio of water, nitric acid and ethanol is 1:0.3:10 to obtain solution A; weigh a certain amount of Ti(OC 4 h 9 ) 4 Dissolved in ethanol to make titanium sol, Ti(OC 4 h 9 ) 4 The molar ratio with ethanol is 1:5; slowly add a certain mass of tetraethyl orthosilicate into the above-mentioned titanium sol, and continue to stir to make it fully miscible, and record it as B; after stirring A and B for 20 minutes, in At room temperature, pour solution A into a rate-controlled injector, then control the injection rate to 4mL / min, and add it dropwise to B under vigorous stirring, and cont...

Embodiment 2

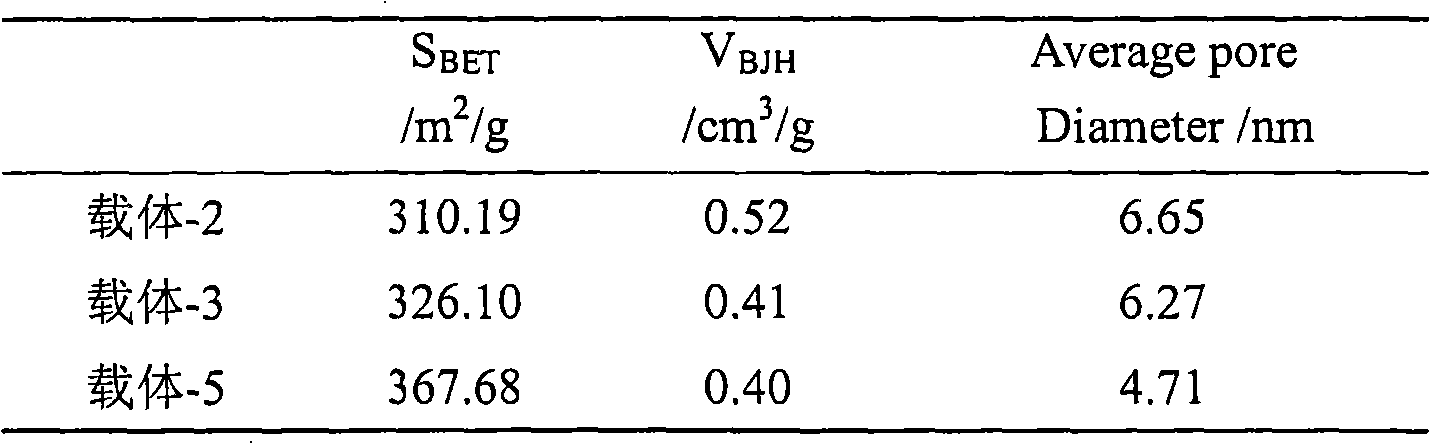

[0046] Prepare the composite carrier according to the method of Example 1, the difference is that the acid uses adipic acid to prepare Al 2 o 3 -SiO 2 -TiO 2 The BET characterization of the series of composite oxides is similar to the result of Example 1.

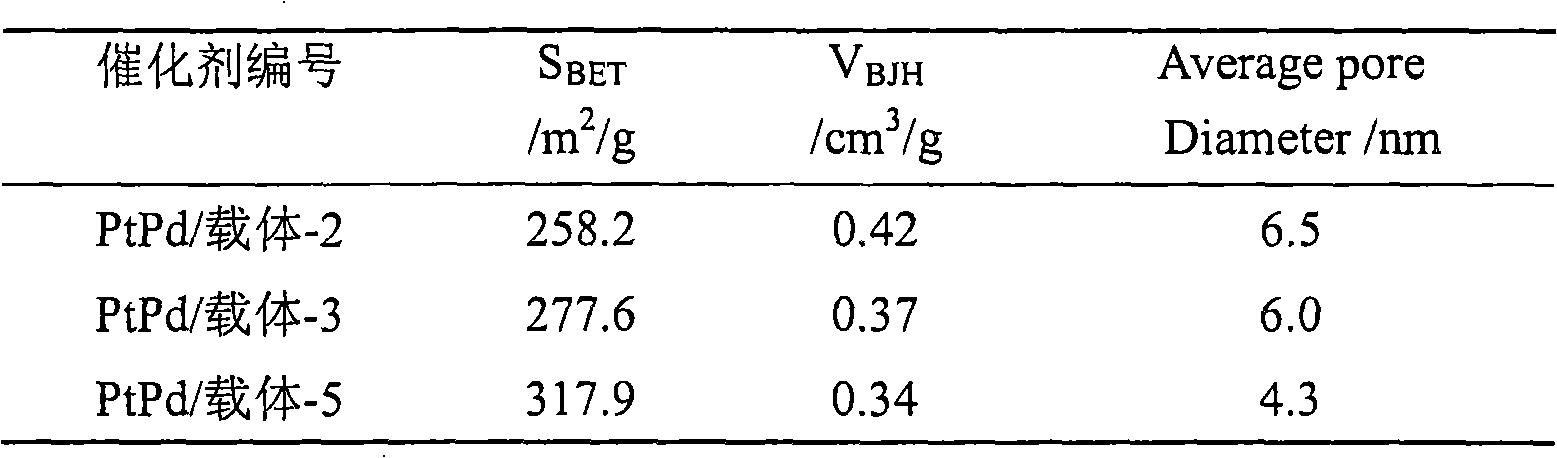

[0047] The support is further impregnated with noble metals Pt and Pd to make PtPd / Al 2 o 3 -SiO 2 -TiO 2 series of catalysts.

Embodiment 3

[0049] With embodiment 1 method, synthesized Al 2 o 3 -SiO 2 -TiO 2 After the composite support, equal volumes of PdPt metal components were co-impregnated on the composite support to prepare PtPd / Al 2 o 3 -SiO 2 -TiO 2 In the catalyst, the mass fraction of Pd is 0.3-0.6%, the mass fraction of Pd is 0.1-0.2%, and the order of impregnation is first Pt and then Pd. The preparation method is: the metal salts used are respectively chloroplatinic acid (H 2 PtCl 6 6H 2 O) and palladium chloride (PdCl 2 ), first a certain amount of chloroplatinic acid (H 2 PtCl 6 6H 2 O) and PdCl 2 Dissolve in 0.2mol / L dilute hydrochloric acid to form a co-impregnation solution, and use the co-impregnation method to obtain PtPd / Al 2 o 3 -SiO 2 -TiO 2 For the double noble metal catalyst precursor, after impregnating the metal active component, put the catalyst precursor into an ultrasonic oscillator for ultrasonic dispersion for 20 minutes, then dry it at 110°C for 12 hours, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com