Polypropylene acid imide foam material and preparation thereof

A technology of polyacrylimide and foam materials, which is applied in the field of polyacrylimide foam materials and its preparation, and can solve the problems of decreased foam performance stability, increased foam brittleness, and difficulty in the uniformity of free radical polymerization reaction systems, etc. problems, to achieve the effect of improving heat resistance, increasing strength and modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

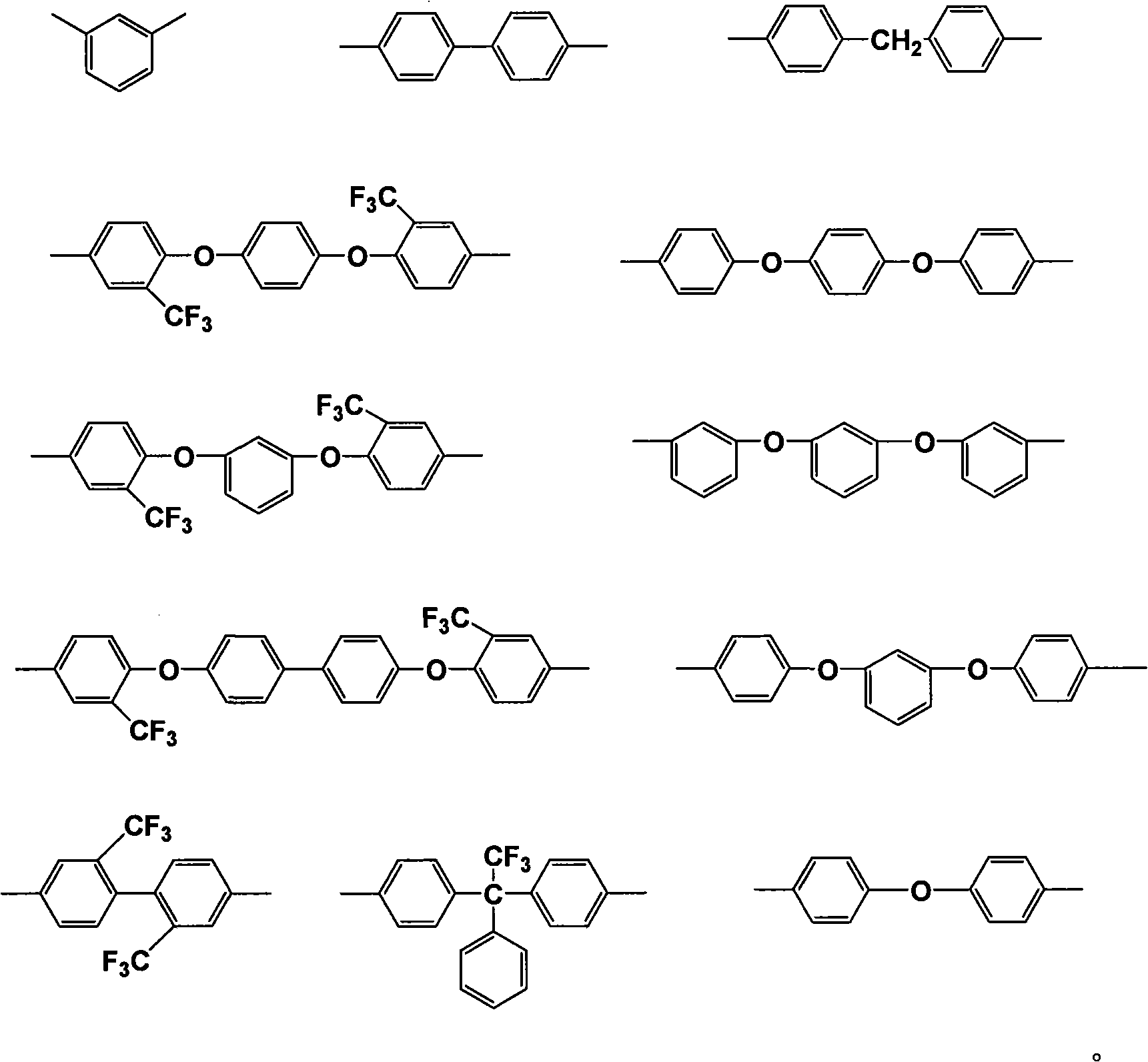

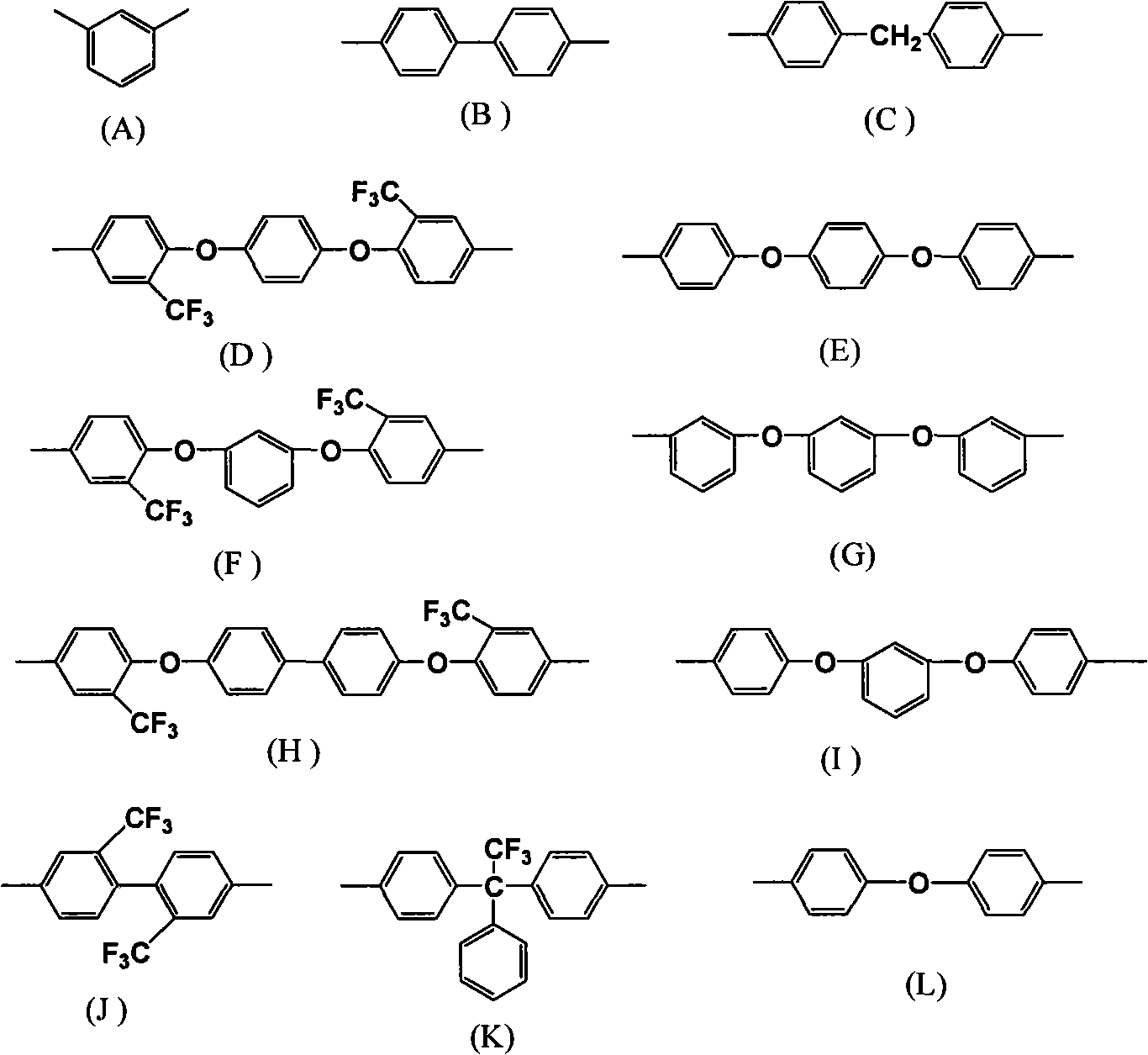

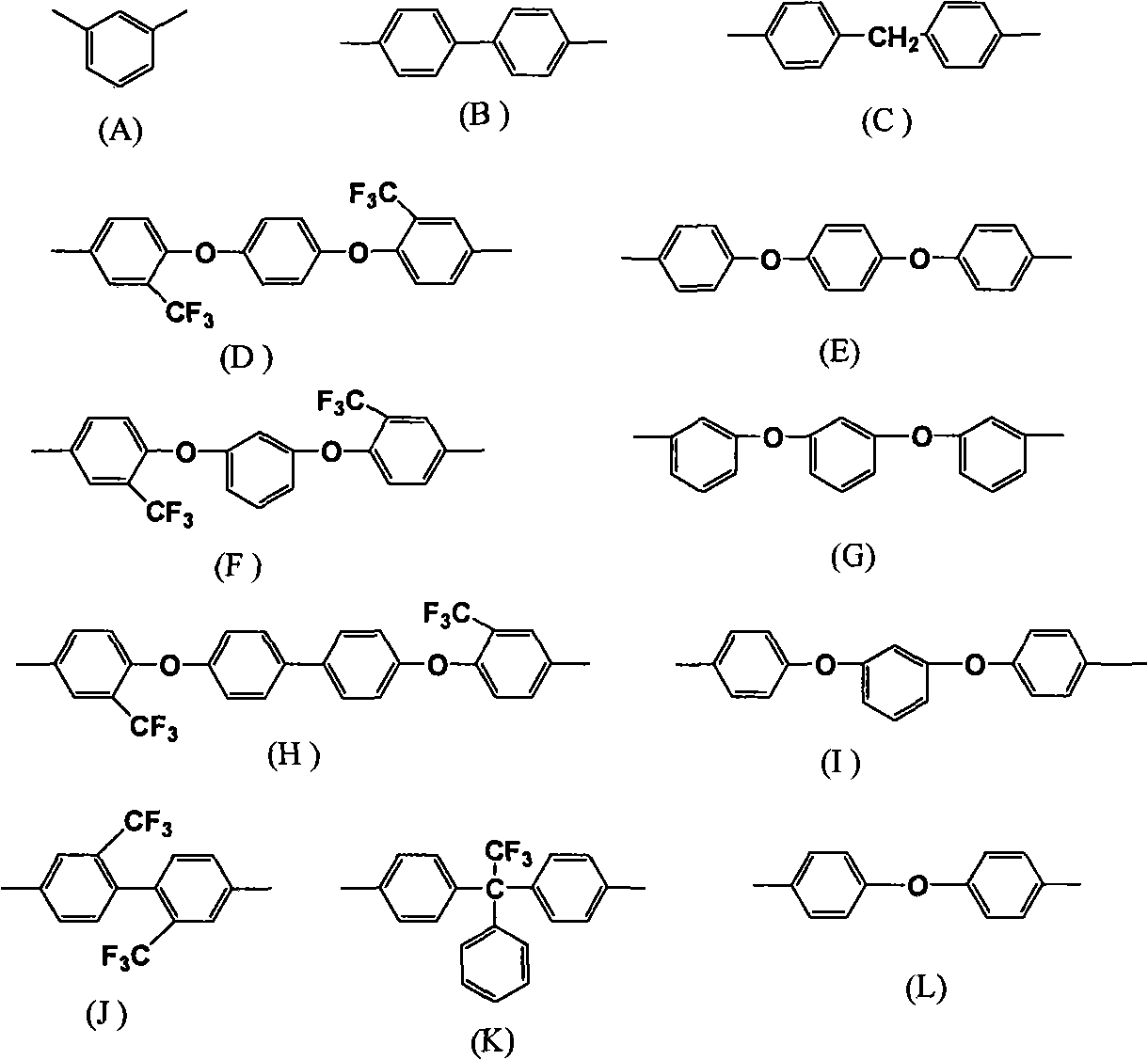

[0034] The preparation method reference of maleimide (Zhu Yulong etc., the synthesis of novel bismaleimide containing ether bond, insulating material, No.5, 2005) is carried out: aromatic diamine is dissolved in electric stirring In the three-neck flask of the device, thermometer and condenser tube, after it is completely dissolved, add maleic anhydride and stir at room temperature for 4 to 5 hours to obtain a bismaleimide solution. In the above-mentioned bismaleimide solution, add a certain amount of acetic anhydride and sodium acetate respectively, stir at room temperature for about 15 minutes, then heat to 60-65°C, continue to react for about 3 hours, after cooling, pour into water , a large number of yellow precipitates were produced, filtered, soaked in acetone, rinsed several times, and dried to obtain maleimide resin powder. The reaction formula is as follows:

[0035]

[0036] Among them, some fluorine-containing diamines can be synthesized according to the method ...

Embodiment 1

[0040]50 parts of methacrylic acid, 50 parts of methacrylonitrile, 25 parts of methacrylamide, 25 parts of bismaleimide resin whose -R- group is a C structure, 10 parts of allyl methacrylate, 10 parts Add formamide, 5 parts of dibenzoyl peroxide, 5 parts of tert-butyl peroxypivalate, 15 parts of isopropanol, 5 parts of INT-PS125, and 3 parts of benzoquinone into a 3000mL three-necked glass flask, Under stirring at room temperature for 2 hours, a homogeneous solution was formed.

[0041] Transfer the above homogeneous solution to a closed system formed by two glass plates and a sealed frame, and polymerize under the following conditions: 50°C / 24h, 60°C~90°C / 58h, 100°C / 1h to obtain the foam precursor Copolymer resin sheet.

[0042] The foam precursor copolymer resin sheet obtained above was foamed at 185°C / 1h to obtain a polymethacrylimide foam sheet blank.

[0043] The polymethacrylimide foam plate blank obtained above is machined to obtain a polymethacrylimide foam material ...

Embodiment 2

[0045] 55 parts of methacrylic acid, 45 parts of methacrylonitrile, 5 parts of bismaleimide resin with C structure in the -R- group, 1.5 parts of formamide, 3 parts of tert-butyl peroxypivalate, 2 parts tert-butyl peroxybenzoate, 1 part of tert-butyl peroxy 2-ethylhexanoate, 5 parts of isopropanol, 3 parts of INT-PS125, and 0.3 part of benzoquinone were sequentially added to a 3000 mL three-necked glass flask, and the Under nitrogen protection, stir at room temperature for 2 hours to form a homogeneous solution.

[0046] Transfer the above homogeneous solution to a closed system formed by two glass plates and a sealed frame, and polymerize under the following conditions: 50°C / 24h, 60°C~90°C / 96h, 100°C~120°C / 3h, to obtain Foam precursor copolymer resin sheet.

[0047] The foam precursor copolymer resin sheet obtained above was foamed at 190° C. / 1 h to obtain a polymethacrylimide foam sheet blank.

[0048] The polymethacrylimide foam plate blank obtained above is machined to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com