Block rare earth gadolinium-based composite amorphous material and preparation thereof

An amorphous material, bulk technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

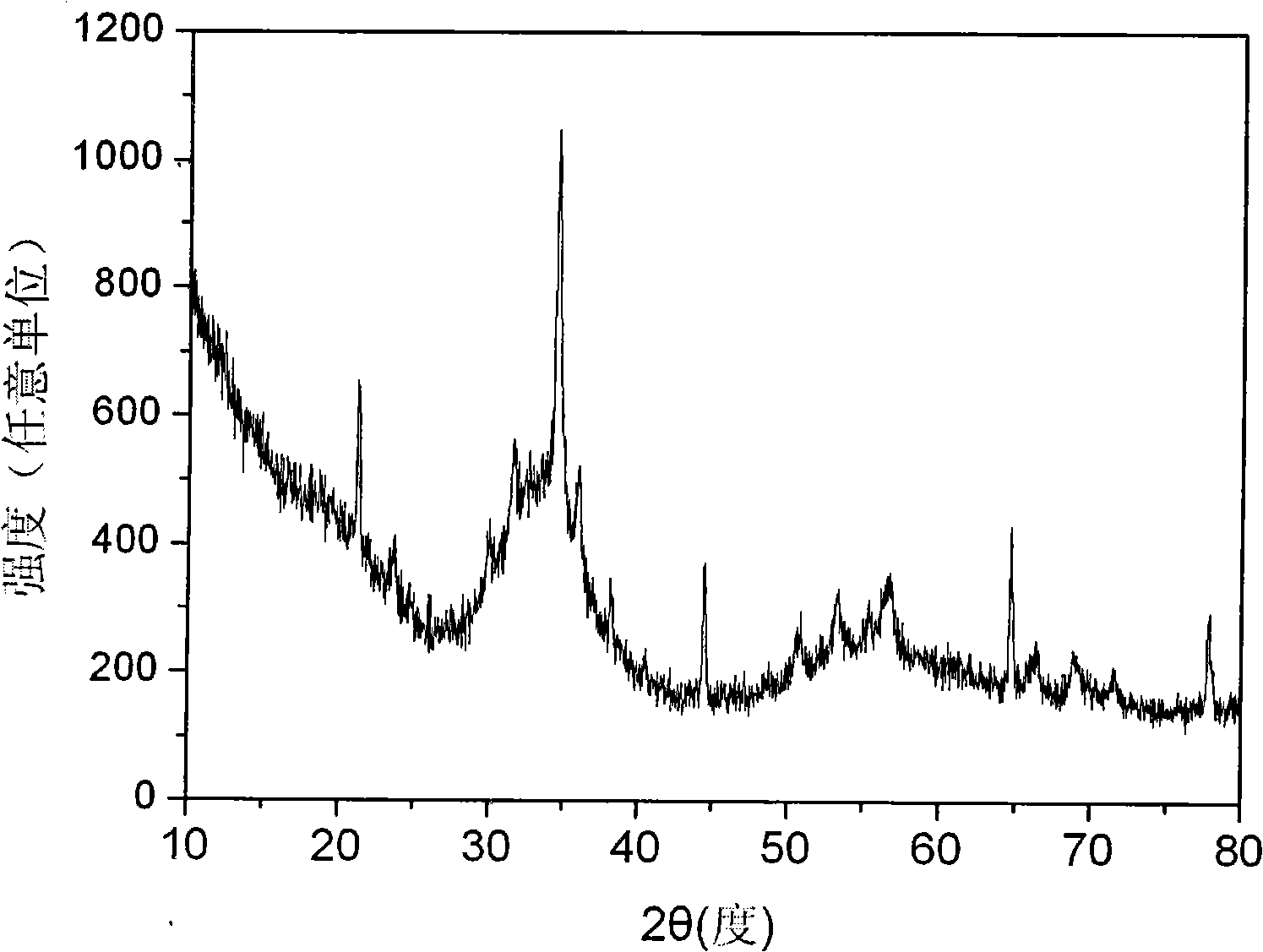

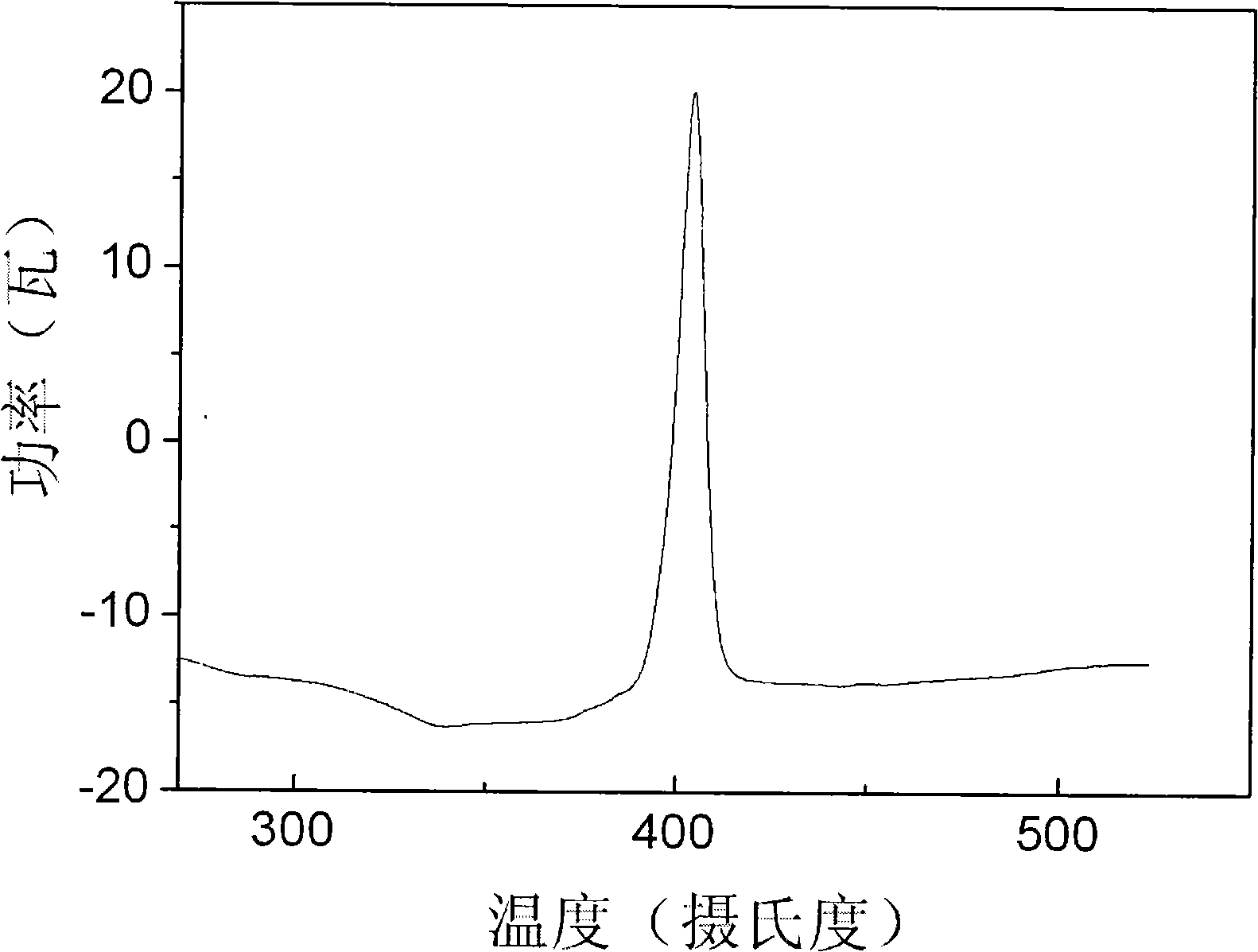

[0030] Example 1Gd 55 co 15 Al 26 Ge 4 Preparation and Thermal Stability of (x=4) Alloy

[0031] The raw materials of gadolinium, cobalt, aluminum and germanium with a purity greater than 99.9% (mass fraction) are classified as Gd 55 co 15 Al 26 Ge 4 Chemical formula weighing, put the prepared raw materials into a non-consumable vacuum electric arc furnace, and evacuate to 3×10 -5 Torr or above; after cleaning 1-2 times with high-purity argon gas cleaning method, under the protection of high-purity argon gas at 1 atmospheric pressure, it is turned over and smelted repeatedly for 4-6 times to make a master alloy; put the master alloy smelted according to the above steps into In the suction-casting copper crucible, the alloy is melted and suction-cast into a columnar sample with a diameter of 10 mm. The metallographic observation shows that the microstructure of the alloy is characterized by a large amorphous matrix and a small amount of primary crystal phase. X-ray diffr...

Embodiment 2

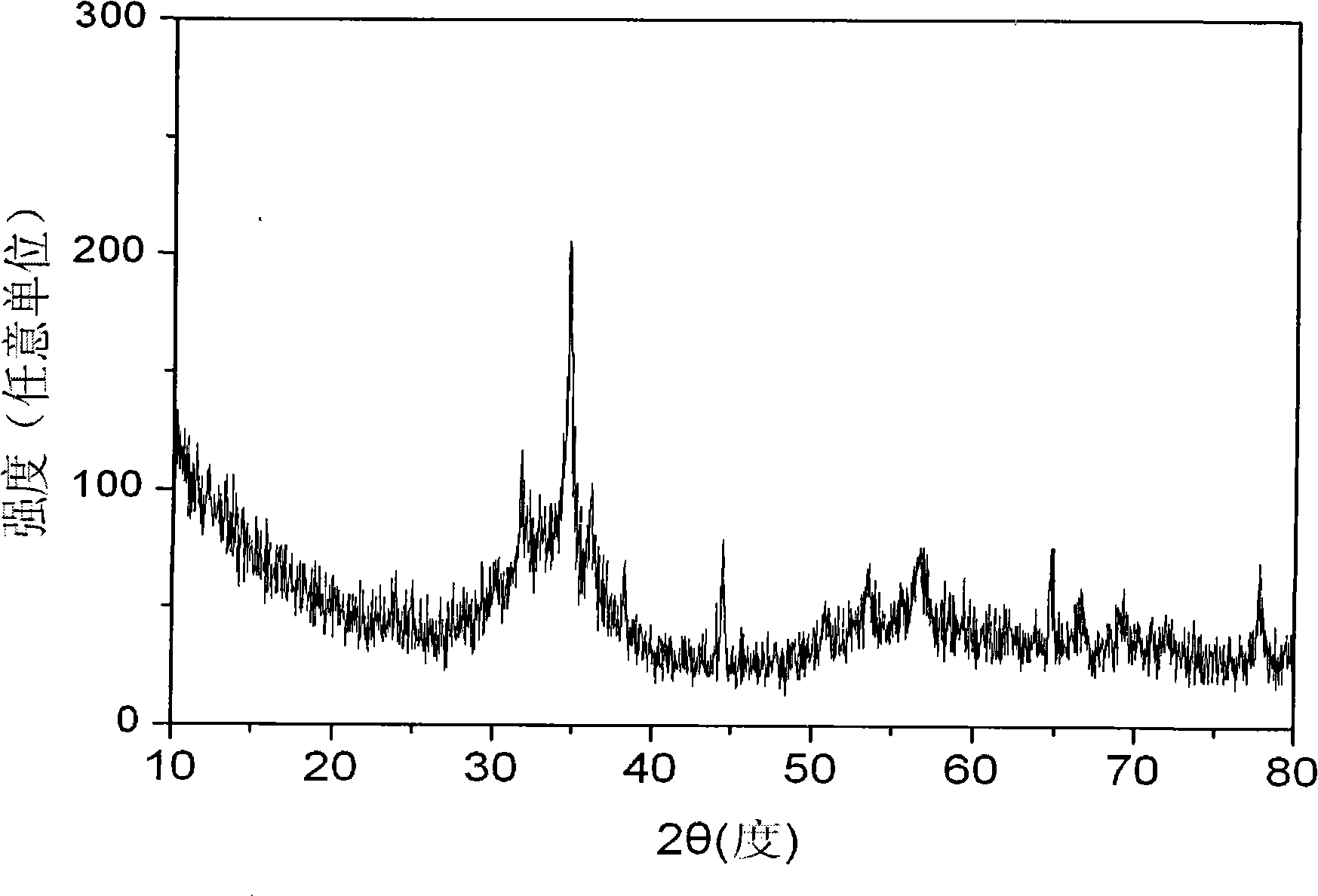

[0032] Example 2Gd 55 co 15 Al 25 Ge 5 Preparation and Thermal Stability of (x=5) Alloy

[0033] The raw materials of gadolinium, cobalt, aluminum and germanium with a purity greater than 99.9% (mass fraction) are classified as Gd 55 co 15 Al 25 Ge 5 Chemical formula weighing, put the prepared raw materials into a non-consumable vacuum electric arc furnace, and evacuate to 3×10 -5 Torr or above; after cleaning 1-2 times with high-purity argon gas cleaning method, under the protection of high-purity argon gas at 1 atmospheric pressure, it is turned over and smelted repeatedly for 4-6 times to make a master alloy; put the master alloy smelted according to the above steps into In the suction-casting copper crucible, the alloy is melted and suction-cast into a columnar sample with a diameter of 10 mm. Metallographic observation shows that the microstructure of the alloy is based on a large amorphous matrix, containing a small amount of primary crystal phase and the primary...

Embodiment 3

[0034] Example 3 Gd 55 co 15 Al 20 Ge 10 Preparation and Thermal Stability of (x=10) Alloy

[0035] The raw materials of gadolinium, cobalt, aluminum and germanium with a purity greater than 99.9% (mass fraction) are classified as Gd 60 co 26 Al 6 Ge 8 Chemical formula weighing, put the prepared raw materials into a non-consumable vacuum electric arc furnace, and evacuate to 3×10 -5 Torr or above; after cleaning 1-2 times with high-purity argon gas cleaning method, under the protection of high-purity argon gas at 1 atmospheric pressure, it is turned over and smelted repeatedly for 4-6 times to make a master alloy; put the master alloy smelted according to the above steps into In the suction-casting copper crucible, the alloy is melted and suction-cast into a columnar sample with a diameter of 10 mm. Metallographic observation shows that the microstructure of the alloy is based on a large amorphous matrix, containing a small amount of primary crystal phase and the prima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Initial crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com