Synthesizing and using method of coal water slurry additive agent

A synthesis method and additive technology are applied in the field of preparing coal-water slurry with excellent performance, which can solve the problems of poor slurry stability and high price, and achieve the effects of good stability, improved performance and improved dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

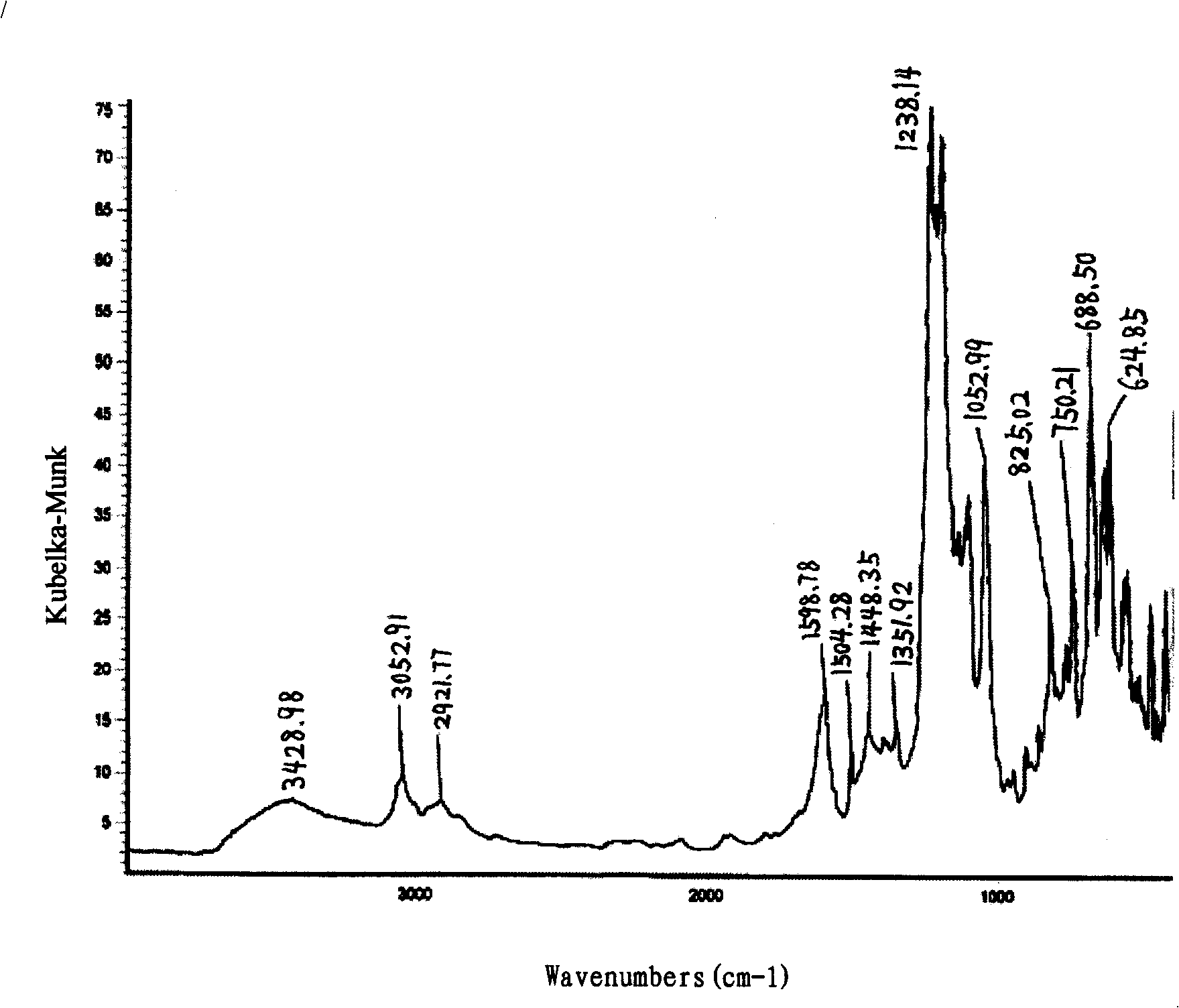

Image

Examples

Embodiment 1

[0016] The synthetic method of coal water slurry additive, step is as follows:

[0017] A Synthesis of anthracene-based additives: first sulfonate crude anthracene, wherein the mass ratio of crude anthracene to concentrated sulfuric acid is 1:0.25-1, the sulfonation temperature is controlled at 90-150°C, the sulfonation reaction time is 2-4h, and then After hydrolysis for 0.5~1h, adjust the pH of the reaction solution to make the pH<3, and then condense with formaldehyde. The mass ratio of crude anthracene to formaldehyde is 1:0.05~0.2, and the condensation temperature is controlled at 100~120°C. and the anthracene-based additives are obtained; B, the polycondensation of sodium naphthalenesulfonate formaldehyde with a degree of polymerization of 10-15 and an average molecular weight of 2000-3500 and the anthracene-based additives prepared in step A are compounded according to a mass ratio of 1:0.2-2 Additives for coal water slurry.

[0018] The mass ratio of crude anthracene ...

Embodiment 2

[0020] Add 150g of crude anthracene to a 500ml four-neck flask, stir, heat until the temperature rises to 110°C, slowly add 40ml of concentrated sulfuric acid dropwise, react at 130°C for 3h, then cool to 120°C, and hydrolyze for 0.5h. Slowly add 10ml of formaldehyde solution into the flask at 100°C and react at 110°C for 1.5h. Neutralize the solution with NaOH to make the pH of the solution 7-9, dry and pulverize to obtain the anthracene additive. Use Xuzhou Pangzhuang coal to prepare coal-water slurry, keep the consumption of coal-water slurry additive as 1% of dry base coal powder, wherein the mass ratio of sodium naphthalenesulfonate formaldehyde polycondensate and the above-mentioned prepared anthracene series coal-water slurry additive is 1: 1. At 24°C, the shear rate is 100s -1 , when the viscosity of the slurry was 1200mPa.s, the concentration of the prepared slurry was 68.2%, and the slurry was stored for 7 days without obvious precipitation.

Embodiment 3

[0022] Substantially the same as in Example 2, by using the sulfonation reaction temperature and the sulfonation reaction time of changing the crude anthracene, concentrated H 2 SO 4 The amount of HCHO, the amount of HCHO and the condensation temperature synthesized anthracene additives for pulping, the concentration of the slurry is 65.5% to 67.4%, and some hard precipitates appear in the slurry after 7 days of storage.

[0023] Wherein the sulfonation temperature is set to 90°C or 110°C or 150°C, the sulfonation reaction time is shortened to 2h, H 2 SO 4 The consumption of HCHO is 30ml, the consumption of HCHO is 15ml, and the condensation temperature is 120°C.

[0024] Example 3:

[0025] In Example 2, other conditions remained unchanged, but the additive used was only sodium naphthalenesulfonate formaldehyde polycondensate, the concentration of the slurry was 68.4%, and hard precipitation occurred after the slurry was stored for 2 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com