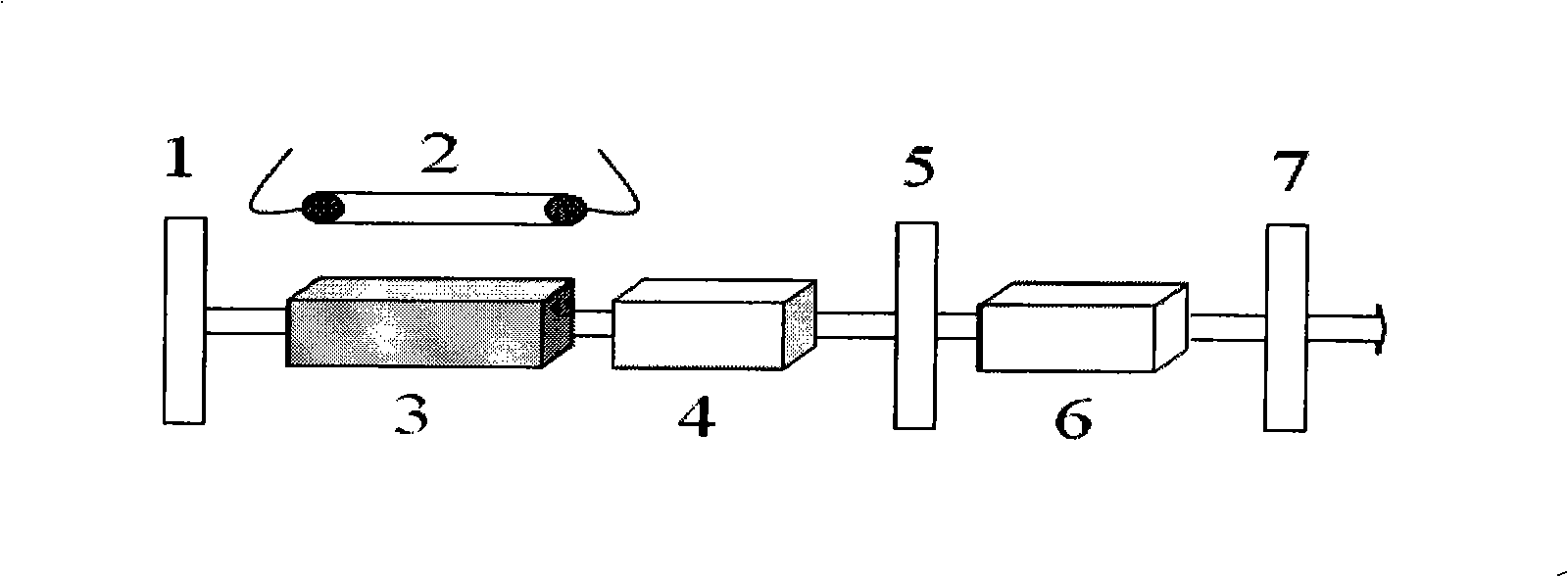

Human eye safe Raman laser based on lanthanum silicate crystal 1.3 mu m electrooptical switch

A Raman laser, eye-safe technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of low light damage threshold, limit the output of eye-safe laser power, etc., and reach the light damage threshold High, high laser output efficiency, high efficiency laser output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: La 3 Ga 5 SiO 14 Preparation of electro-optic crystals.

[0029] La 2 o 3 , Ga 2 o 3 , SiO 2 As the raw material, according to the chemical equation: 3La 2 o 3 +5 Ga 2 o 3 +2 SiO 2 = 2 La 3 Ga 5 SiO 14 According to the stoichiometric ratio or Ga 2 o 3 Excessive 1~2wt.% Weigh the raw materials, mix the prepared raw materials evenly, place them in a platinum crucible, sinter at a temperature of 1100 ° C for 10 hours, then grind the sintered raw materials again, then press them into pieces, and place them in a platinum crucible again , and sintered at 1100°C for 10 hours, you can get La 3 Ga 5 SiO 14 of polycrystalline material. Put the configured La3 Ga 5 SiO 14 The polycrystalline material is placed in the iridium crucible, the single crystal furnace is evacuated, filled with protective gas nitrogen, and heated up; the medium frequency heating method is used, and the La in the c direction is used. 3 Ga 5 SiO 14 Seed crystal, the pullin...

Embodiment 2

[0032] Example 2: BaWO 4 Crystal preparation.

[0033] Using BaCO 3 , WO 3 As the starting material according to the chemical equation: BaCO 3 +WO 3 = BaWO 4 +CO 2 , formulated to grow BaWO in a stoichiometric ratio 4 Crystalline polycrystalline material (WO 3 Excessive 1wt.%), the prepared raw materials are placed in a platinum crucible, sintered at a temperature of 1100 ° C for 10 hours, then the sintered raw materials are ground again, then pressed into pieces, placed in a platinum crucible again, and sintered at 1100 ° C for 10 hours , you can get BaWO 4 of polycrystalline material. Put the configured BaWO 4 The polycrystalline material is placed in the iridium crucible, the single crystal furnace is evacuated, filled with protective gas nitrogen, and heated up; the medium frequency heating method is used, and the BaWO in the a direction is used 4 Seed crystal, the pulling speed of crystal growth is 0.5-2 mm / hour, the rotation speed is 10-30 rpm, and BaWO is obt...

Embodiment 3

[0036] Example 3: SrWO 4 Crystal preparation.

[0037] Using SrCO 3 , WO 3 For the initial raw material according to the chemical equation: SrCO 3 +WO 3 =SrWO 4 +CO 2 , growing SrWO in a stoichiometric configuration 4 Crystalline polycrystalline material (WO 3 Excessive 1wt.%), the configured raw materials are placed in a platinum crucible, sintered at a temperature of 1100 ° C for 10 hours, then the sintered raw materials are ground again, then pressed into pieces, placed in a platinum crucible again, and sintered at 1100 ° C for 10 hours , you can get SrWO 4 of polycrystalline material. Put the configured SrWO 4 The polycrystalline material is placed in the iridium crucible, the single crystal furnace is evacuated, filled with protective gas nitrogen, and heated up; the medium frequency heating method is used, and the SrWO in the c direction is used 4 For the seed crystal, the pulling speed for crystal growth is 0.5-2 mm / hour, and the rotation speed is 10-30 revol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com