Polyester type hyperbranched polymer pigment dispersant and preparation thereof

A technology of hyperbranched polymer and pigment dispersant, applied in chemical instruments and methods, dyeing polymer organic compound treatment, chemical/physical process, etc., can solve the problem of poor color brightness and vividness, coarse particles and uneven distribution of pigments. and other problems, to achieve the effect of low production cost, simple synthesis method and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

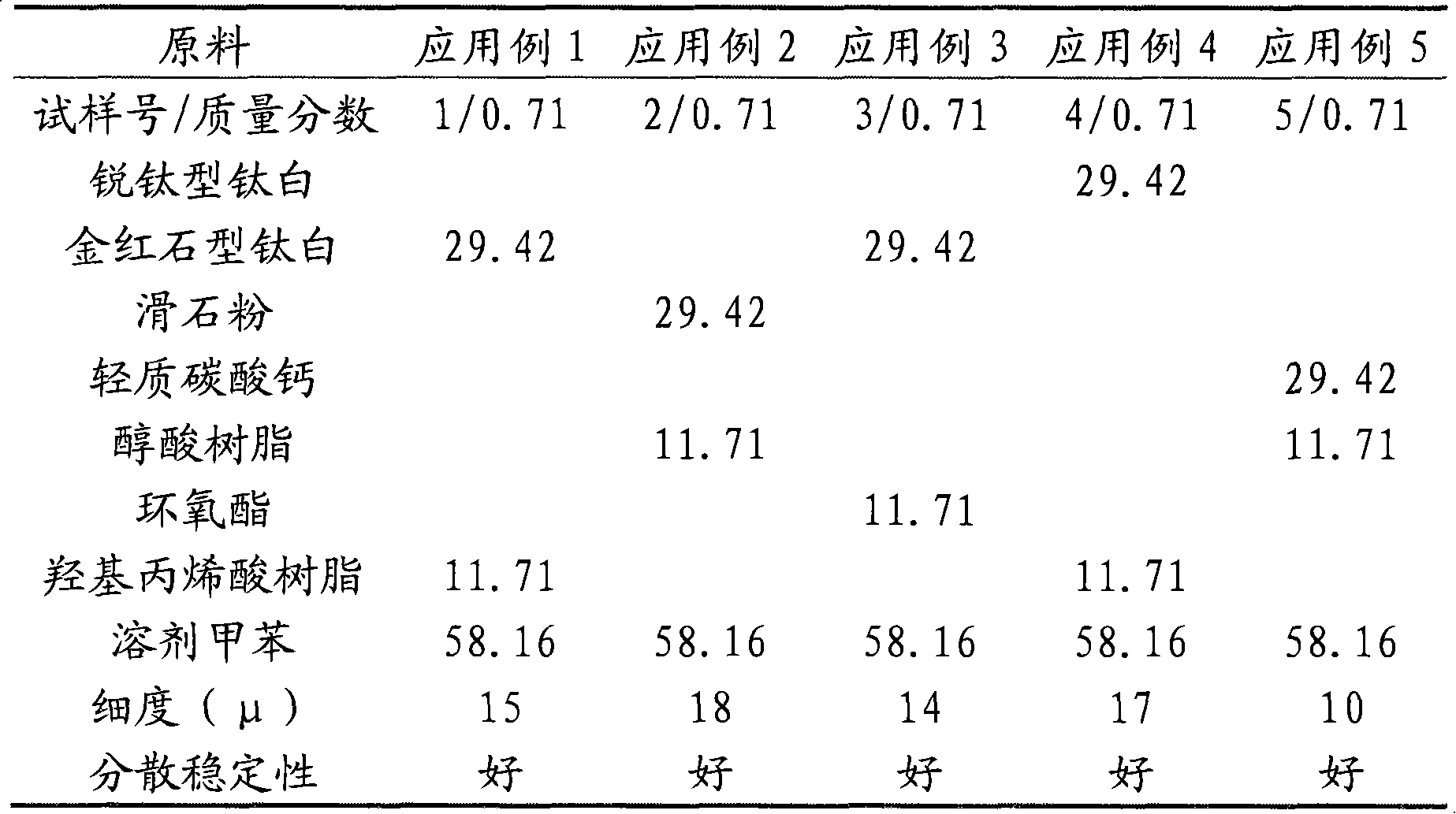

[0013] Example 1: Add 0.1 moles of trimethylolpropane, 2.1 moles of dimethylolbutanoic acid and 1% of the total mass of reactants into a four-necked flask equipped with a stirrer, thermometer and condenser. Acid catalyst, heating, after the material is melted, start stirring and turn on the vacuum pump, control the reaction temperature to 140℃, the vacuum degree is 1000Pa, after 3 hours, the temperature is raised to 180℃, the vacuum degree is controlled at 60Pa, and the measurement is performed every 1 hour after 5 hours. Acid value, until the acid value is stable, it is the end of the reaction, and the yellow solid product is the third-generation hyperbranched polyester; remove the vacuum and stop the operation of the vacuum pump, add 0.6 mol of lauric acid to the flask while it is hot, stir and evacuate , Control the temperature at 180℃, and the vacuum at 60Pa. After 5 hours, measure the acid value every 1 hour until the acid value is stable, which is the end of the reaction. Th...

Embodiment 2

[0014] Example 2: Add 0.1 moles of pentaerythritol, 1.2 moles of dimethylolpropionic acid, and 4.5% of the total mass of the reactant phosphomolybdic acid catalyst into a four-necked flask equipped with a stirrer, a thermometer and a condenser, and heat the material to be After melting, start stirring and turn on the vacuum pump, control the temperature at 140°C and the vacuum degree at 800Pa. After 3 hours, the temperature is raised to 200°C, and the reaction is controlled at 20Pa to continue the reaction. After 5 hours, the acid value is measured every 1 hour until the acid value is reached. Stability is the end of the reaction, and the second-generation hyperbranched polyester is obtained as a light yellow viscous liquid; remove the vacuum and stop the operation of the vacuum pump, add 0.2 moles of stearic acid to the flask while it is hot, stir and vacuum, and control the temperature to 200 ℃, the vacuum degree is 20 Pa, after 5 hours, the acid value is measured every 1 hour u...

Embodiment 3

[0015] Example 3: Add 0.93 moles of diisopropanolamine and 0.93 moles of succinic anhydride into a four-necked flask equipped with a stirrer, thermometer and condenser. After heating and melting, the reaction is continued for 1 hour at the melting temperature, and then to Add 0.01 mole of trimethylolpropane to the reactor, heat it and wait until the materials are all melted, start stirring and turn on the vacuum pump, control the temperature at 140°C and the vacuum degree to proceed with the polycondensation reaction under the conditions of 4kPa, and then heat up to 190°C after 3 hours , The vacuum degree is 120Pa to continue the reaction, and the acid value is measured every 1 hour after 5 hours, until the acid value is stable, it is the end of the reaction, and the yellow solid is obtained as the fifth-generation hyperbranched polyester; the vacuum pump is stopped at the same time as the vacuum pump is removed. , Add 0.45 moles of oleic acid to the four-neck flask while it is ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com