Production method of fermented milk

A technology for fermented milk and fresh milk, applied in the directions of dairy products, applications, milk preparations, etc., can solve the problems of unacceptable, difficult and convenient manufacture of fermented milk, unable to achieve the probiotic function of various intestinal bacteria, and achieve inhibition of angiotensin The formation of cerebrovascular disease, the prevention of cerebrovascular disease, the effect of excellent health preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Utilize Bacillus natto to make fermented milk

[0057] 1. Prepare Bacillus natto dry powder

[0058] In this embodiment, a dried Bacillus natto powder is used to provide Bacillus natto. The dry bacillus natto powder is dried commercially available natto and made into powder. One gram (g) of Bacillus natto dry powder includes 10 9 The colony forming unit (CFU), that is, the concentration of Bacillus natto dry powder that Bacillus natto adopts in the present embodiment is 1 * 10 9 CFU / g.

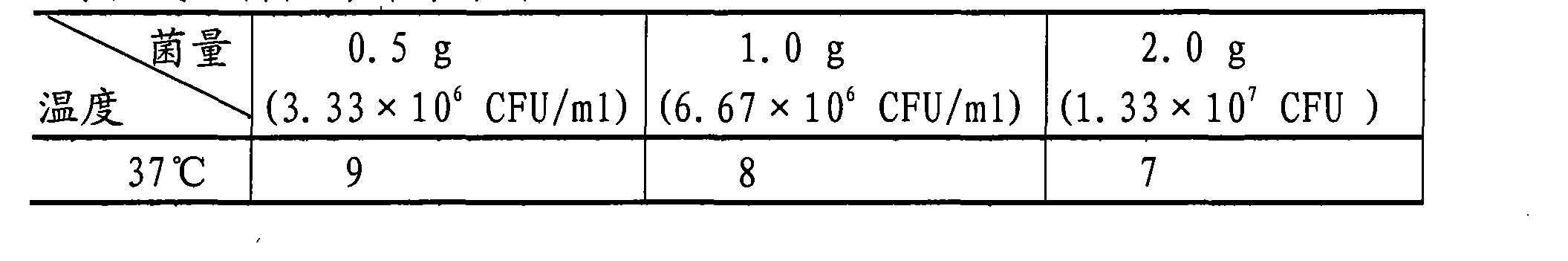

[0059] 2. Fermented low-fat fresh milk

[0060] Take 150 public pinches (ml) of commercially available low-fat fresh milk in an appropriate container, add one gram of the aforementioned dried Bacillus natto powder to prepare a Bacillus natto content of 6.67×10 6 CFU / ml of low-fat fresh milk. After stirring evenly, place at 37°C. Curdled milk is produced in the process of forming Bacillus natto fermented milk, and light green whey (whey or milk plasma) is produced. ...

Embodiment 2

[0062] Example 2: Making Bacillus natto fermented milk with different dosages of Bacillus natto and different temperatures

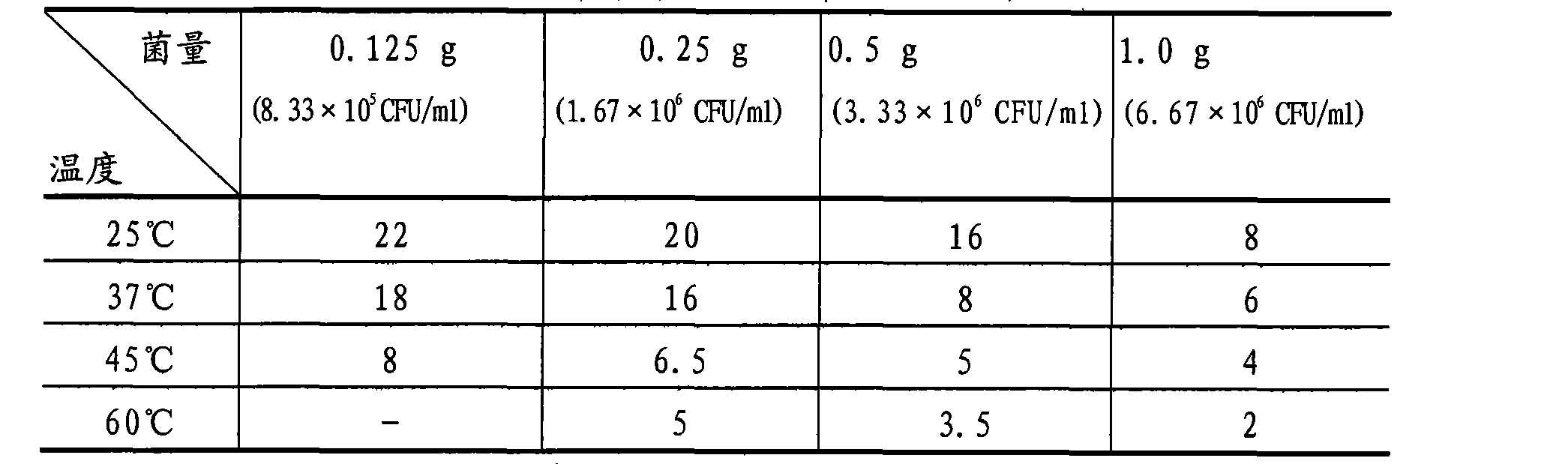

[0063] Put 150ml of low-fat fresh milk in a suitable container as one serving of low-fat fresh milk, with four servings of low-fat fresh milk as a group, and prepare four groups of 0.125 grams, 0.25 grams, 0.5 grams and 1.0 grams. In each serving of low-fat fresh milk in the 0.125-gram group, 0.125 grams of dry Bacillus natto powder was added. The remaining 0.25 g, 0.5 g, and 1.0 g groups were also added in the same manner to each portion of low-fat fresh milk with dry Bacillus natto powder.

[0064] By adding dried Bacillus natto powder, the concentration of Bacillus natto in a portion of low-fat fresh milk of the aforementioned four groups was adjusted to 8.33×10 5 CFU / ml, 1.67×10 6 CFU / ml, 3.33×10 6 CFU / ml and 6.67×10 6 CFU / ml. Next, place four parts of low-fat fresh milk in each group at 25°C (room temperature), 37°C, 45°C, and 60°C respectively...

Embodiment 3

[0070] Embodiment three: utilize skimmed milk powder to make natto fermented milk

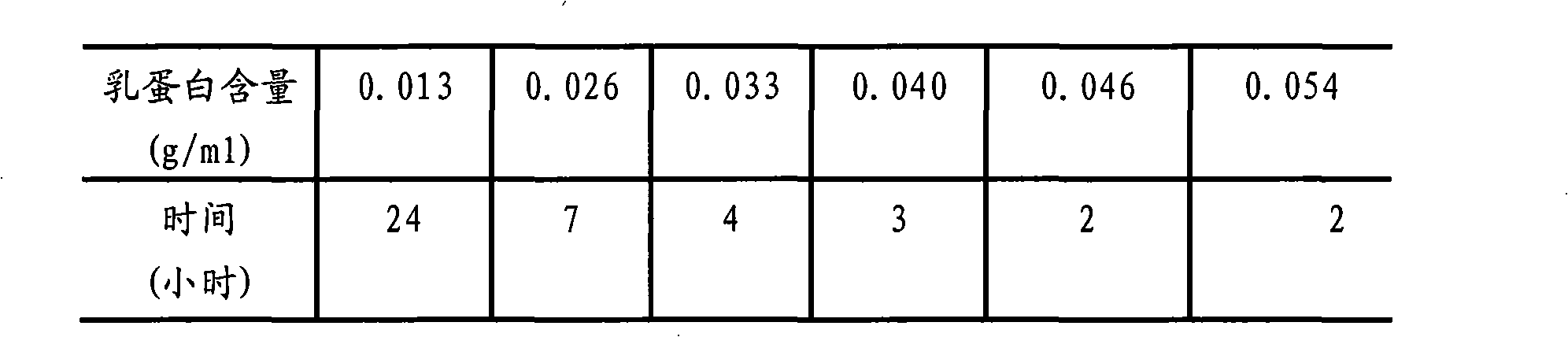

[0071] Since many commercially available fermented milks mostly use skim milk powder as a raw material, this example uses skim milk powder to make skim fermented milk, and thereby explores the influence of different milk protein contents on the production of Bacillus natto fermented milk.

[0072] Please refer to Table 2, take 6g (milk protein 0.013g / ml), 12g (milk protein 0.026g / ml), 15g (milk protein 0.033g / ml), 18g (milk protein 0.040g / ml) of commercially available skim milk powder respectively , 21g (milk protein 0.046g / ml) and 24g (milk protein 0.054g / ml) were stirred evenly with warm boiled water and quantified to 150ml. 9 CFU), stirred evenly, placed at 37°C for cultivation, observed every hour, and recorded the time required for coagulation, the termination time was as in the aforementioned second embodiment, subject to the visual observation of whey. It has been observed that the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com