Method for producing cement clinker from paper manufacture waste slag mud

A technology for cement clinker and paper-making waste residue, applied in cement production and other directions, can solve problems such as land occupation and environmental pollution, and achieve the effects of less land occupation, simple process method and quick start-up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

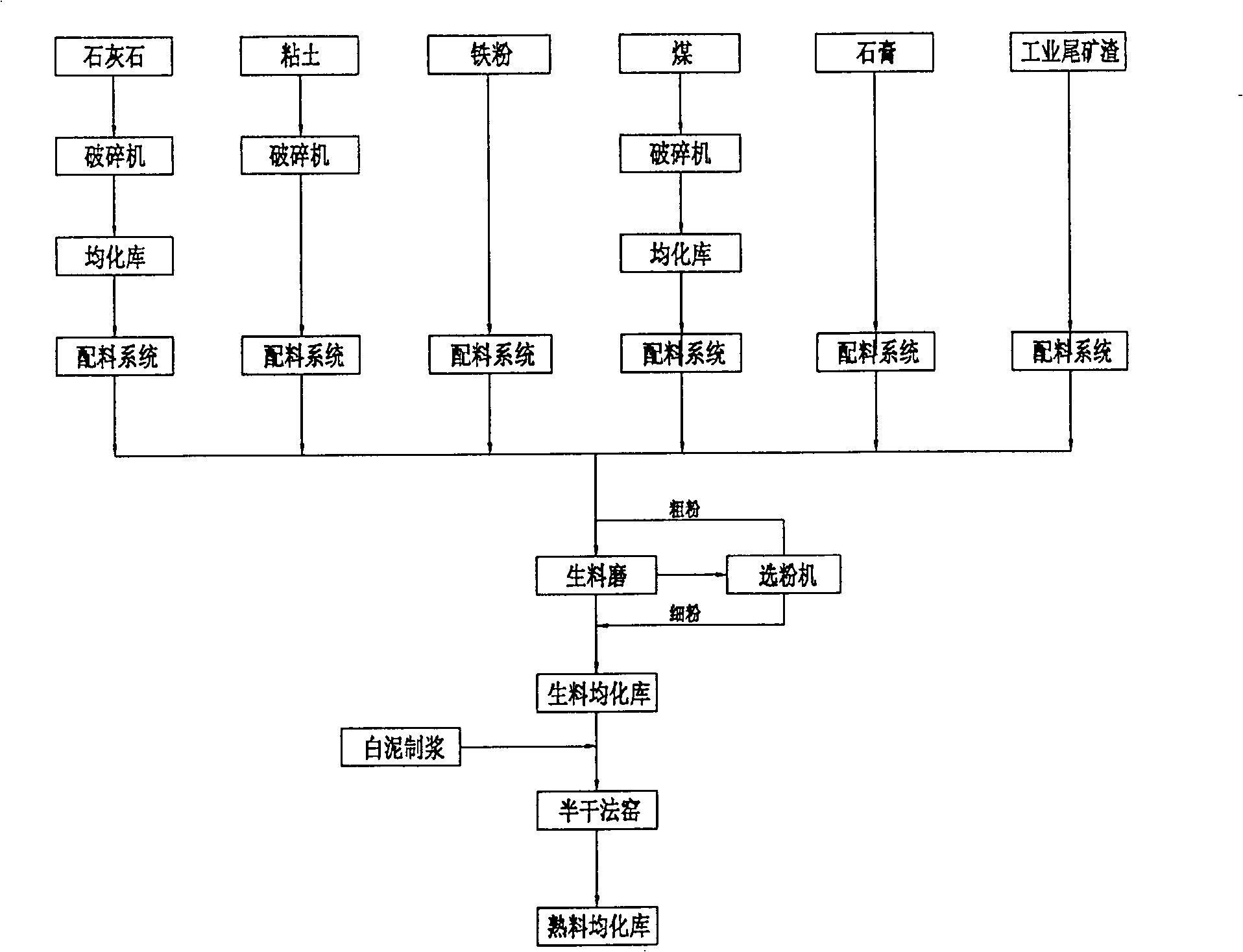

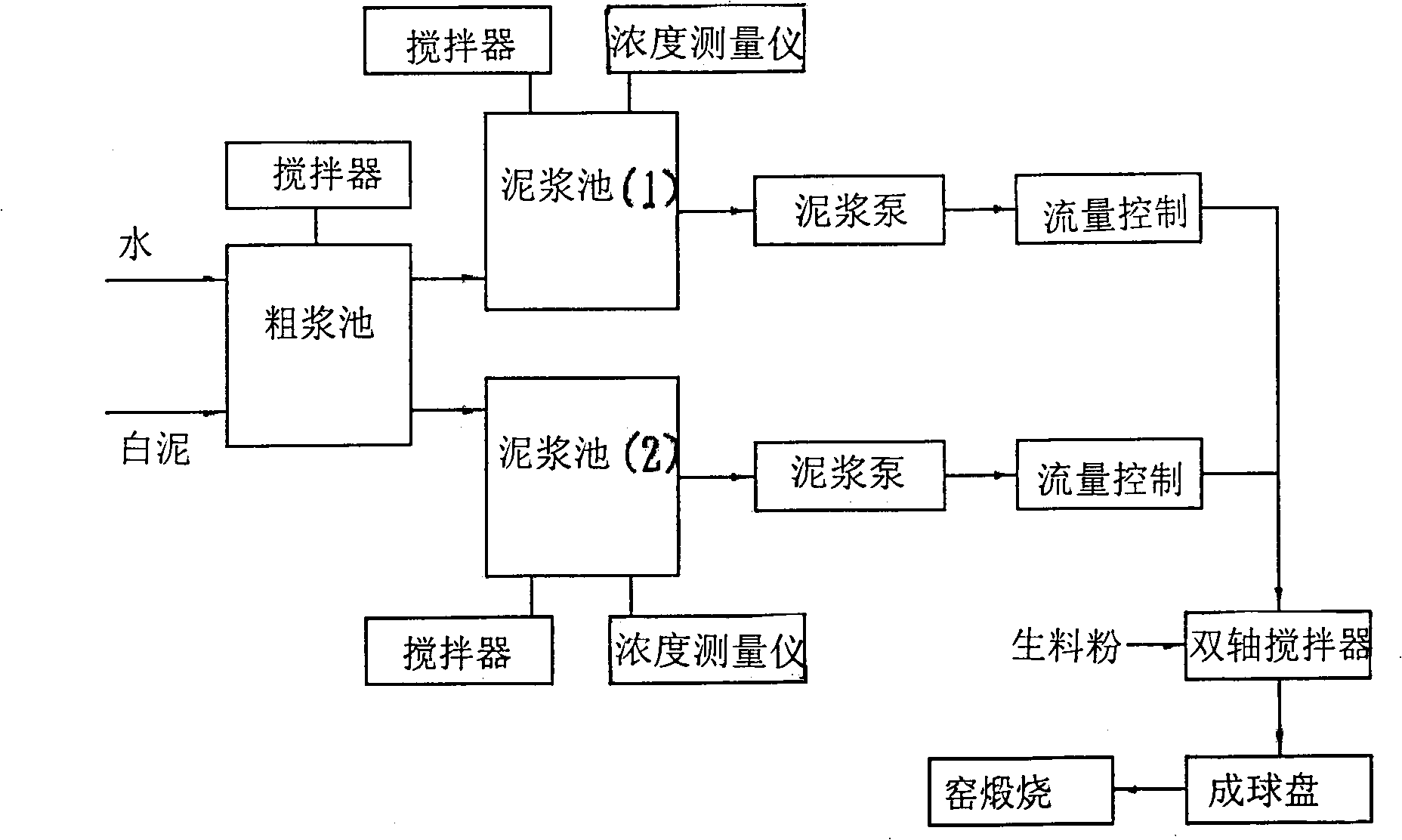

[0011] 1. Raw meal preparation: Based on the annual output of 360,000 tons of clinker, 576,000 tons of raw meal will be consumed; 100,000 tons of lime mud (with a moisture content of about 50% and a CaO content of about 40%) will be mixed into the 576,000 tons of raw meal , the amount of limestone mixed is 284,300 tons; the moisture content of the limestone is about 50%, after being diluted with water, it is replaced by water for ball formation, the limestone is stirred, and then it is calcined in the kiln after being balled into balls; 0.125 tons of water / ton of raw meal, 7.2 tons of water;

[0012] 11% clay, 9% white coal, 3% iron material, 1% gypsum, 3% water slag, one or more combinations of them can also be added to the raw meal.

[0013] Two, clinker calcining (prior art): after the raw material is formed into balls, it is calcined in a cement kiln until it is partially melted to obtain tricalcium silicate, dicalcium silicate, tricalcium aluminate, and tetracalcium alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com