Drying method for reducing oxidation of water-bearing articles

A drying method and food technology, which is applied in the direction of drying machines for static materials, drying solid materials, drying gas arrangement, etc., can solve the problems that vacuum equipment is unfavorable for large-scale food processing, mildew preservation effect, etc., and achieve food preservation and anti-oxidation Time-extended, easy-to-master, simple-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

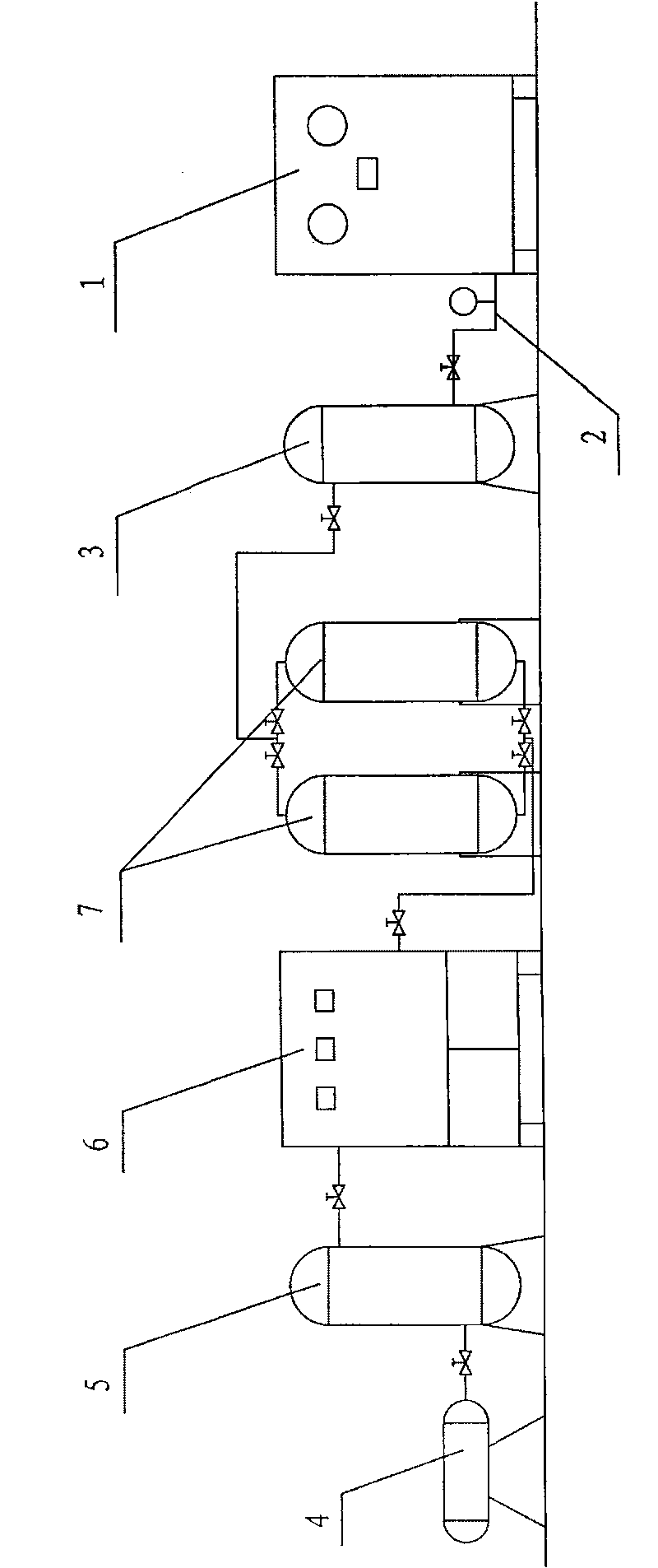

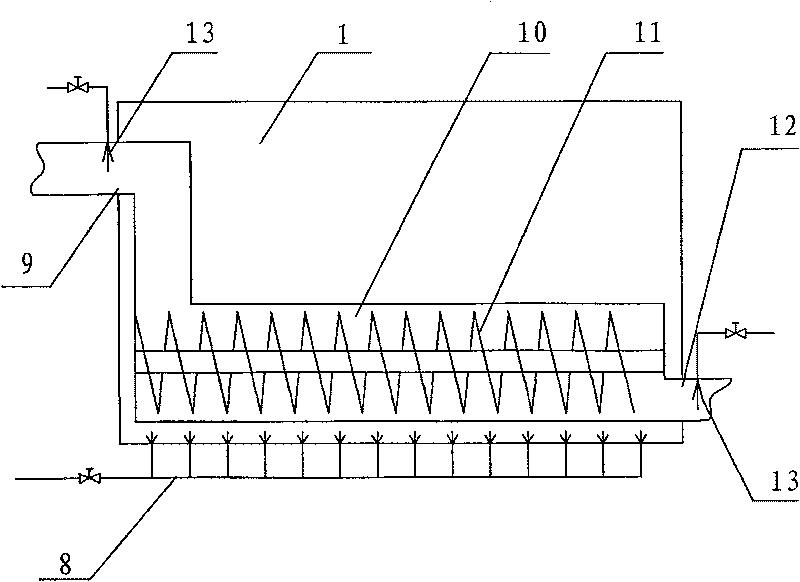

[0018] This embodiment is a drying method for reducing the oxidation of water-containing items, see figure 1 , the dry processing equipment of this method comprises drier 1, is provided with nitrogen inlet pipe 2 on drier, and nitrogen inlet pipe is connected with a nitrogen storage tank 3, and equipment also includes a set of nitrogen making system, and this system includes air compressor 4 , air storage tank 5, cooling dryer 6, pressure swing adsorption nitrogen generator 7; the compressed air of the air compressor is pressed into the air storage tank, and the cooling dryer connected to the air storage tank cools and dehumidifies the air, and is connected with the cooling dryer The pressure swing adsorption nitrogen generator realizes the separation of nitrogen and oxygen in the air and provides nitrogen with a purity of 90% to 99.9% to the nitrogen storage tank; the temperature and humidity control in the dehydration and drying process of the items in the dryer adopts differ...

Embodiment 2

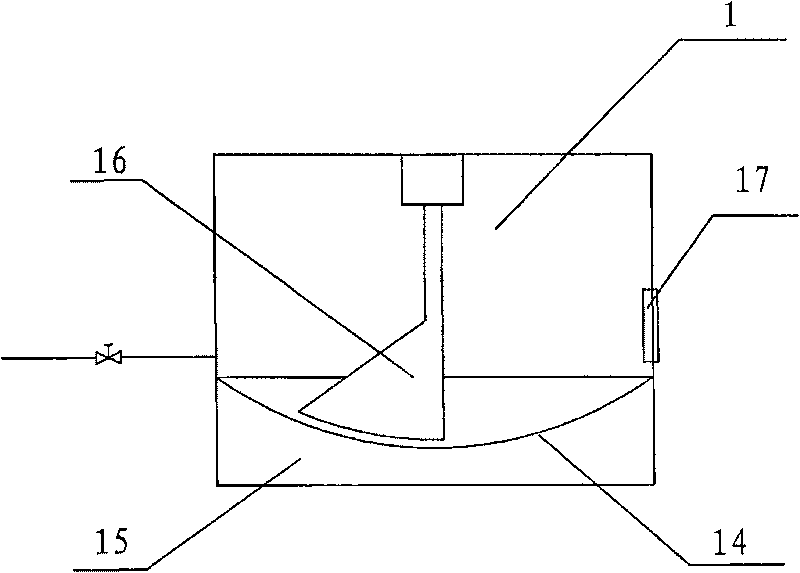

[0025] Referring to Embodiment 1, the drier described in this embodiment is a container, such as a room for placing articles (such as a wood drying treatment room), or a container for storing articles (such as a bag or box for filling food), or a In the drying box on the production line (such as the drying box section on the instant noodle production line, the drying section on the pharmaceutical production line), the container is equipped with a nitrogen gas input port and a nitrogen gas output port, and the effective area of the nitrogen gas input port can be greater than The effective area of the nitrogen output port, the article is put into the container, and the nitrogen is continuously sent into the container from the nitrogen input port of the container after being heated to ensure that the container is always under positive pressure. The nitrogen temperature after the heating is Item drying process temperature, the moisture content of the item is controlled within t...

Embodiment 3

[0031] Referring to Embodiment 1 and Embodiment 2, the desiccator described in this embodiment is a closed container. After the article is placed in the desiccator container, the airtight container is first vacuumed, and then nitrogen is charged into the desiccator container. The airtight container is always under positive pressure, usually the pressure in the container is kept between 0.001MPa and 0.002MPa, and then it is operated according to the traditional drying, heating and dehumidification process.

[0032] Since the whole process of drying the items is completed in an environment filled with nitrogen, the possibility of contact with oxygen-containing air in the initial stage of dehumidification and drying of the items is avoided, and the storage time and freshness of the items such as food after drying are improved. sex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com