Method for carbon supported ultra-low platinum catalytic electrode preparation by indirect galvanic deposit

A catalytic electrode and electrodeposition technology, applied to battery electrodes, fuel cell parts, circuits, etc., to achieve the effect of low platinum loading and high electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1), preparation of microporous layer

[0042] First, soak the carbon paper in an aqueous ethanol solution, vibrate for 30 minutes under ultrasonic conditions, then soak it in a 30% polytetrafluoroethylene emulsion for 30 minutes, and then bake it in a muffle furnace at a temperature of 340 ° C for 40 minutes to obtain a hydrophobic paper. diffusion layer. Weigh polytetrafluoroethylene and Vulcan XC-72 carbon powder according to the mass ratio of PTFE: Vulcan XC-72 carbon powder is 1:1, then use ethanol as solvent to oscillate evenly under ultrasonic conditions, and apply it several times On the surface of the pretreated carbon paper, it was finally placed in a muffle furnace at a temperature of 340° C. and baked for 45 minutes to obtain a microporous layer.

[0043] (2) Preparation of porous carbon electrodes bonded with perfluorosulfonic acid resin

[0044] Perfluorosulfonic acid resin: the mass ratio of Vulcan XC-72 carbon powder is 1: 30 to take perfluorosulfonic ...

Embodiment 2

[0057] Steps (1)-(2) are the same as steps (1)-(2) in Example 1.

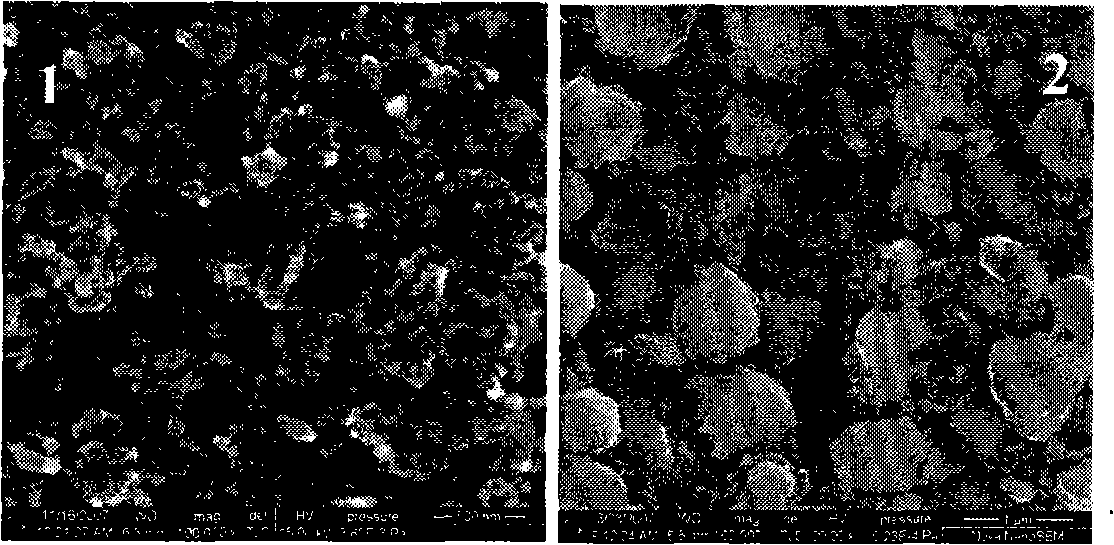

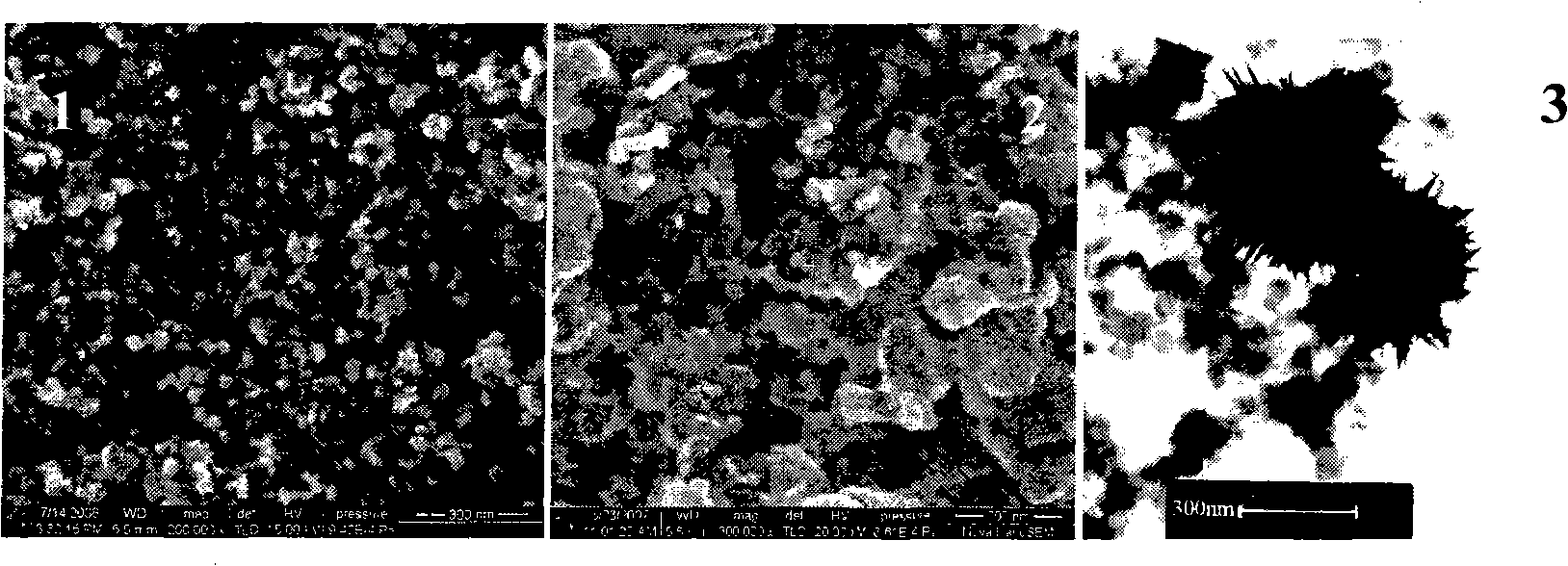

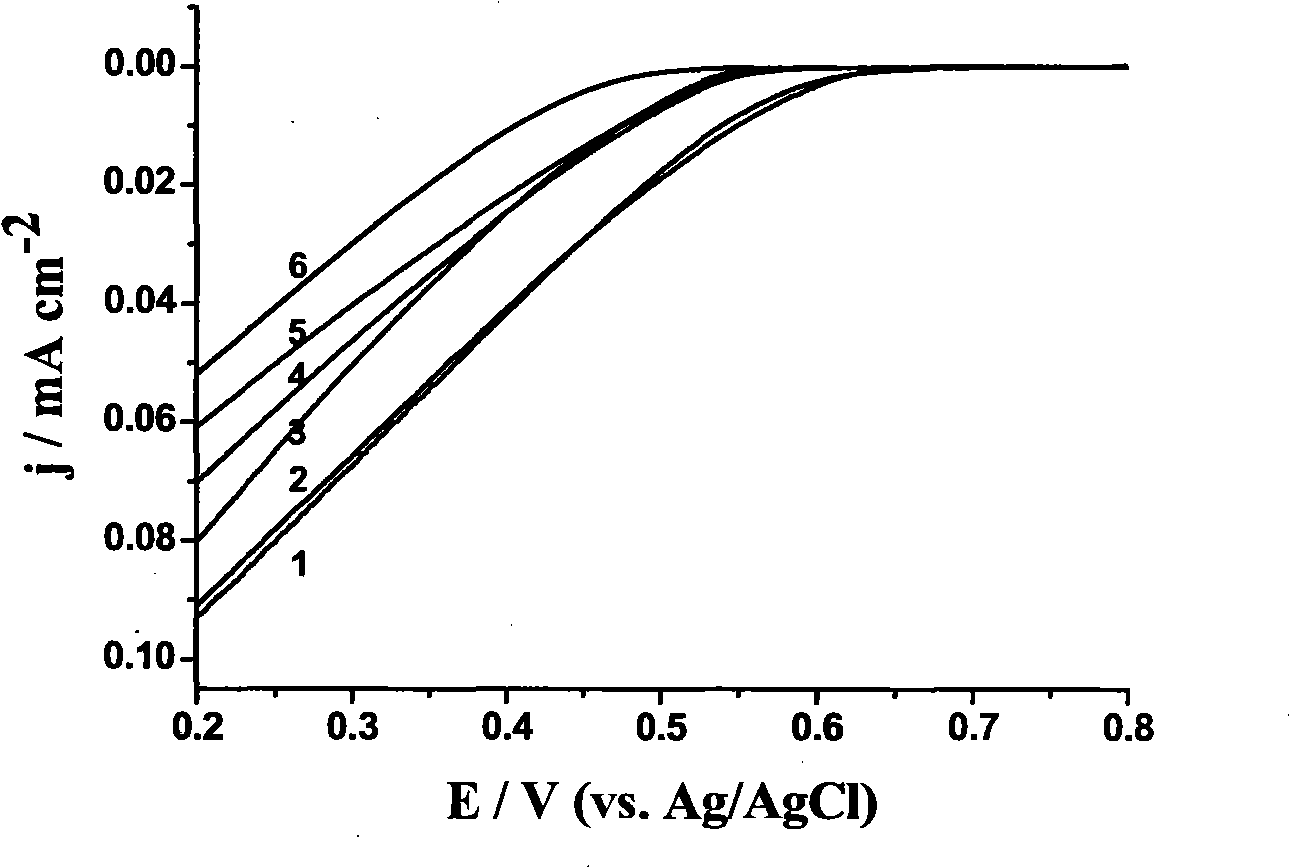

[0058] (3) Four-step electrodeposition method to prepare highly dispersed Cu / PCE electrodes with controllable size

[0059] Adopt two-electrode system, the perfluorosulfonic acid resin bonded porous carbon electrode that makes with the step (2) is cathode, and metal copper is anode; Electrolyte is 0.25g / L copper sulfate and 98g / L sulfuric acid solution, electrodeposition The temperature is 10°C, and a four-step electrodeposition method is used to prepare a highly dispersed Cu / PCE electrode with controllable size on a perfluorosulfonic acid resin-bonded porous carbon electrode. The process parameters of the four-step electrodeposition are:

[0060] The first step: the peak current density is 0.1A / dm 2 , the conduction time is 150s;

[0061] Step 2: The peak current density is 5A / dm 2 , the conduction time is 5s;

[0062] Step 3: The peak current density is 0.1A / dm 2 , the conduction time is 120s;

[0063] ...

Embodiment 3

[0068] Steps (1)-(2) are the same as steps (1)-(2) in Example 1.

[0069] (3) Four-step electrodeposition method to prepare highly dispersed Cu / PCE electrodes with controllable size

[0070] Adopt two-electrode system, the perfluorosulfonic acid resin bonding porous carbon electrode that makes with (2) step is negative electrode, and metal copper is anode; Electrolyte is 188g / L copper nitrate and 196g / L sulfuric acid solution, electrodeposition temperature At 25°C, a four-step electrodeposition method was used to prepare a highly dispersed Cu / PCE electrode with controllable size on a perfluorosulfonic acid resin-bonded porous carbon electrode. The process parameters of the four-step electrodeposition were:

[0071] Step 1: The peak current density is 0.5A / dm 2 , the conduction time is 100s;

[0072] Step 2: The peak current density is 10A / dm 2 , the conduction time is 3s;

[0073] Step 3: The peak current density is 0.5A / dm 2 , the conduction time is 60s;

[0074] Step 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com